Composite material rectangular tube floating body stand system floating on water for photovoltaic power generation and manufacturing and mounting process for composite material rectangular tube floating body stand system

A composite material and photovoltaic power generation technology, which is applied to floating buildings, transportation and packaging, ship parts, etc., can solve the problems that it is difficult to meet the 25-year life cycle requirements of photovoltaic power plants, achieve mass production and improve service life , The effect of convenient installation and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

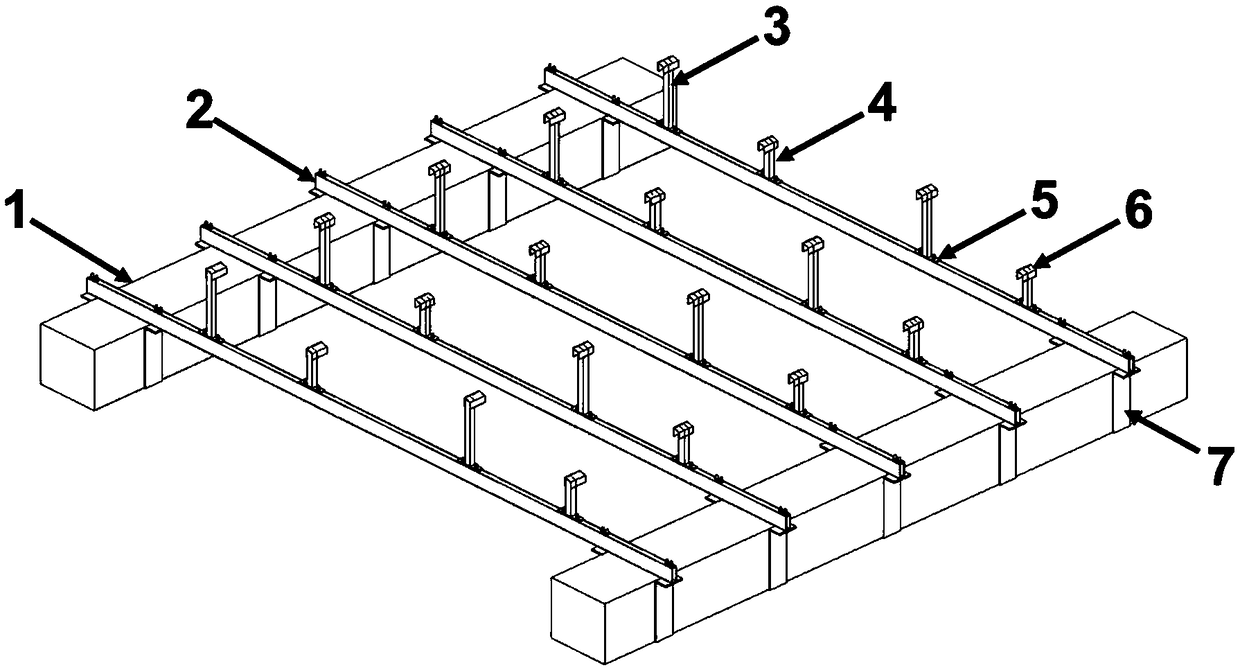

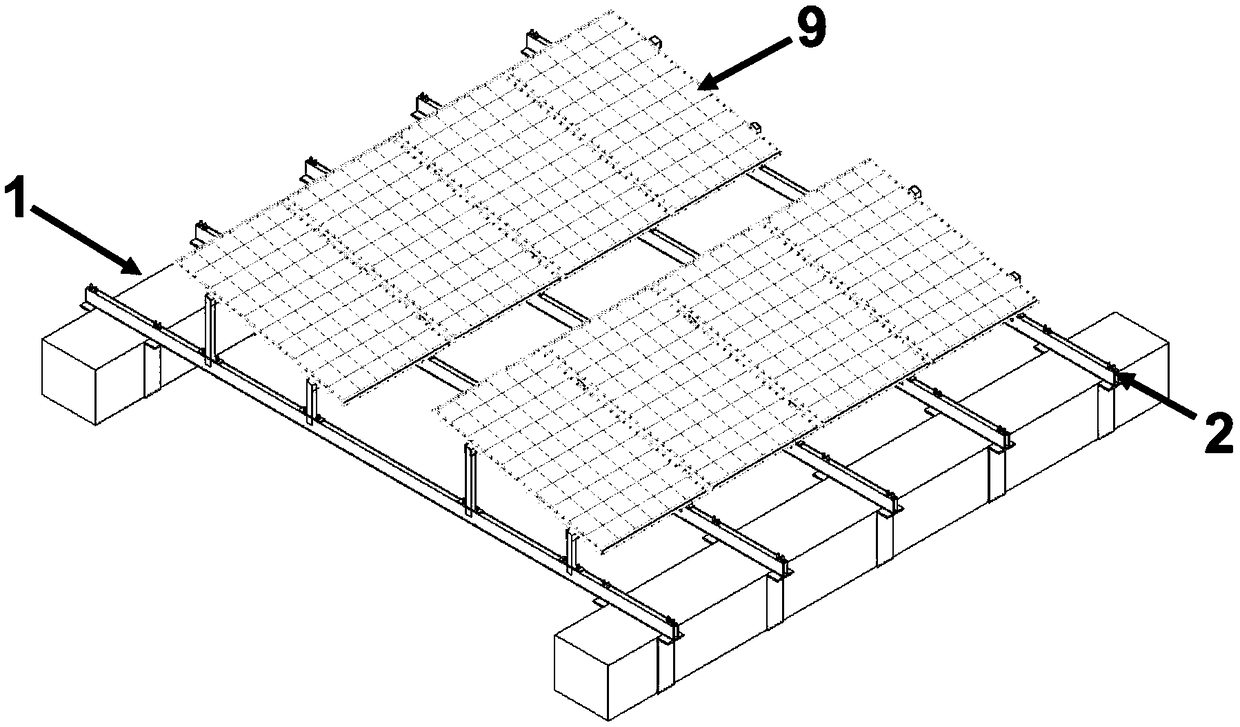

[0035] Such as figure 1As shown in -9, a composite material rectangular tube floating body mounting system for floating photovoltaic power generation on water, the floating body mounting system includes a composite material rectangular tube floating body main beam 1, galvanized steel, composite material or aluminum alloy rectangular tube floating body secondary beam 2 and galvanized steel, composite or aluminum alloy railless brackets.

[0036] The connection between the main girder 1 of the composite rectangular tube floating body and the secondary beam 2 of the rectangular tube floating body made of galvanized steel, composite material or aluminum alloy is divided into two types: 1. along the axial direction of the main girder 1 of the rectangular tube floating body made of composite material The groove-shaped composite material hoops 7 are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap