Powder unloading device

A technology of unloading device and powder, applied in the directions of loading/unloading, transportation and packaging, conveyor, etc., can solve the problems of dispersing the powder that cannot be agglomerated, affecting drug production, etc., so as to reduce the possibility of agglomeration and improve the The effect of looseness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

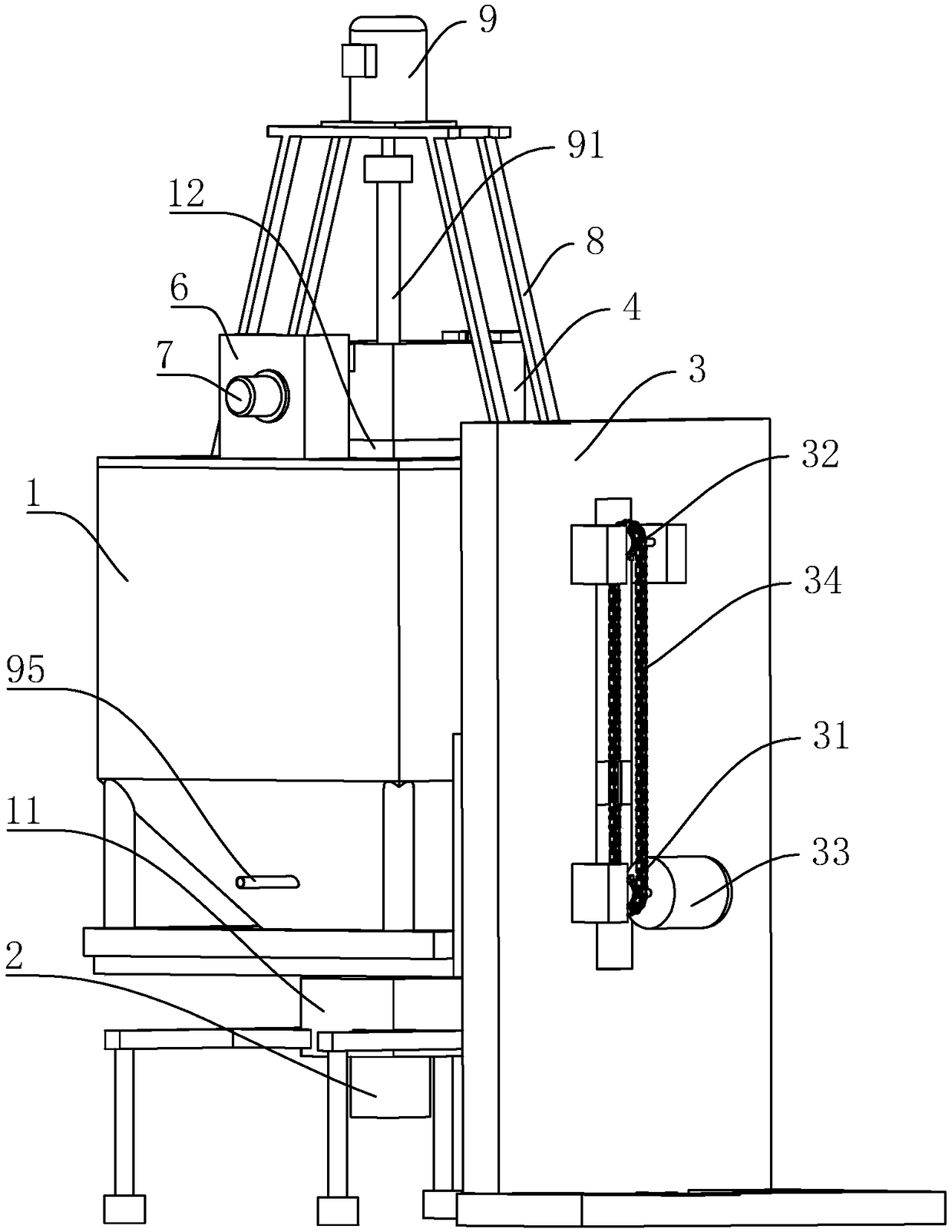

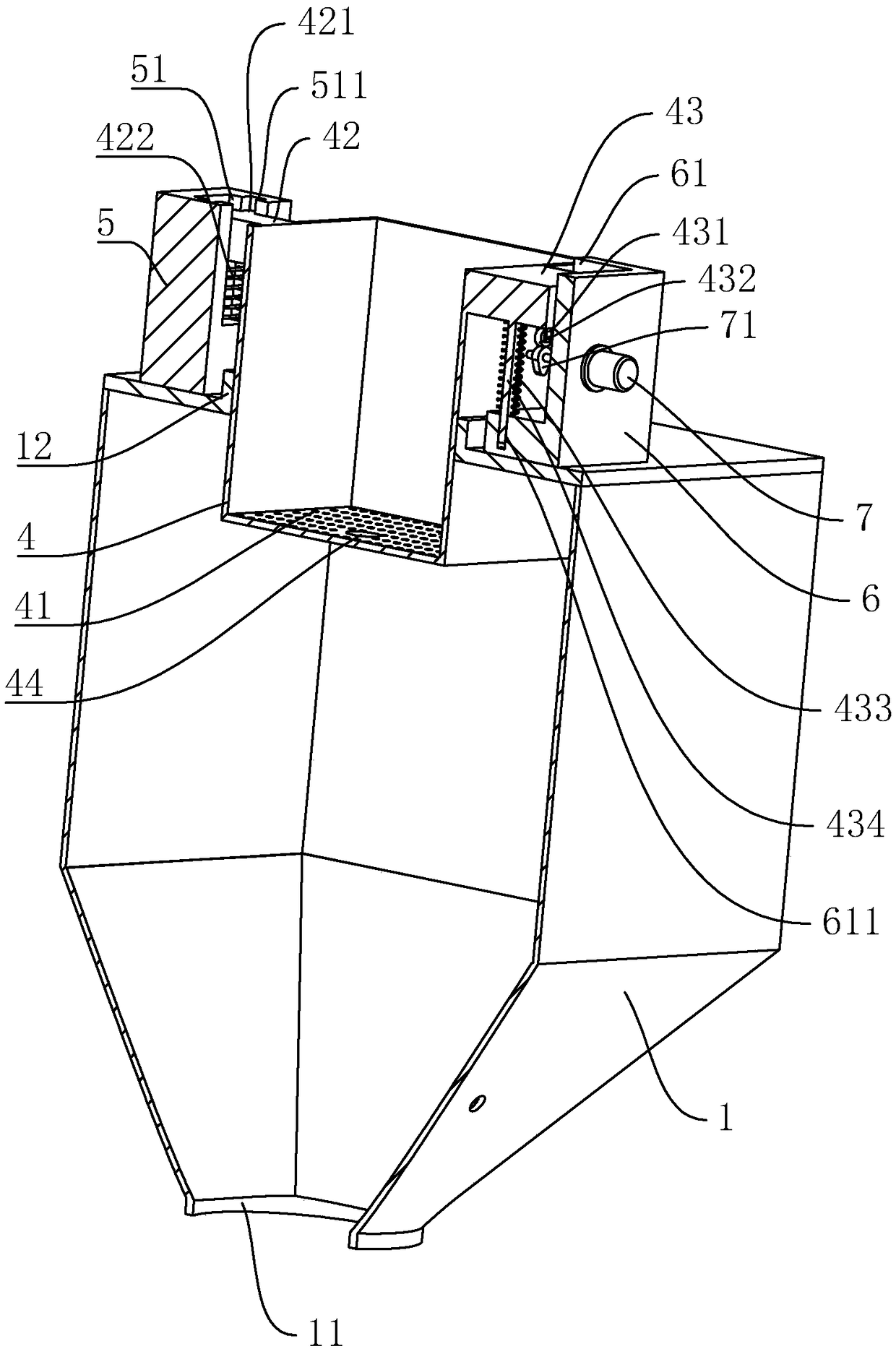

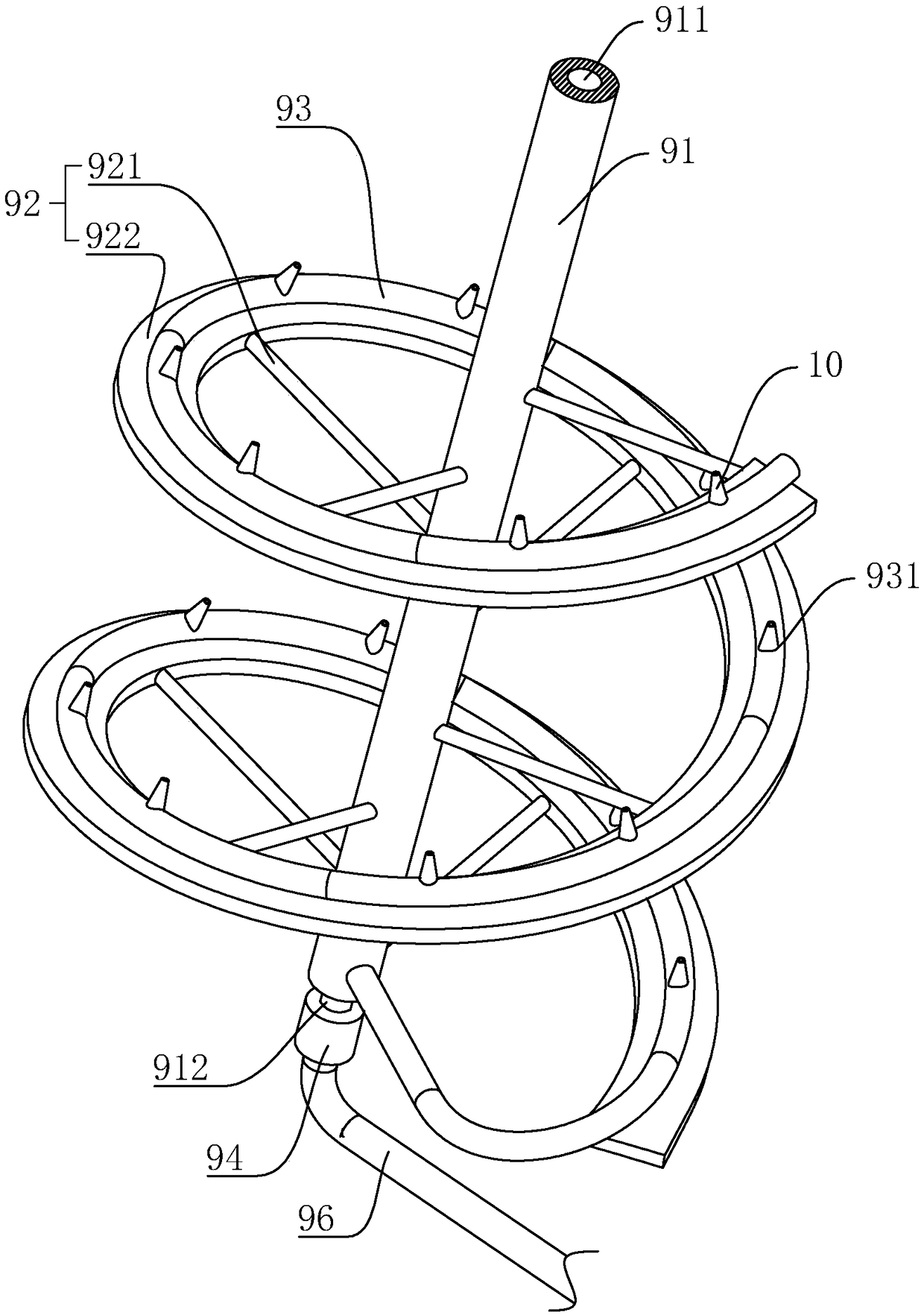

[0032] Embodiment: a kind of medicine powder unloading device, refer to figure 1 , including a discharge hopper 1, a discharge barrel 2 and a frame 3. The discharge cylinder 2 is fixedly connected to the frame 3 , and the discharge hopper 1 is located above the discharge cylinder 2 and is slidably connected to the frame 3 . One side that is positioned at frame 3 is provided with driving sprocket 31 and driven sprocket 32, and driving sprocket 31 is connected with driving motor 33, and driving sprocket 31 and driven sprocket 32 is connected with lifting chain 34, and discharge hopper 1 can Dismantling is connected to lifting chain 34. When working, the driving motor 33 is used to drive the lifting chain 34 to rotate, thereby driving the unloading hopper 1 to rise and fall.

[0033] refer to figure 1 , a discharge port 11 is arranged below the discharge hopper 1 , and the discharge port 11 is facing the discharge cylinder 2 . A feed inlet 12 is provided above the discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com