A kind of method preventing sodium thiocyanate from agglomerating

A technology of sodium thiocyanate and anti-caking agent, which is applied to thiocyanate, devices for coating liquid on the surface, special surfaces, etc., can solve the problems that caking cannot be completely prevented, and achieve the effect of ensuring anti-caking, The effect of reducing the possibility of caking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

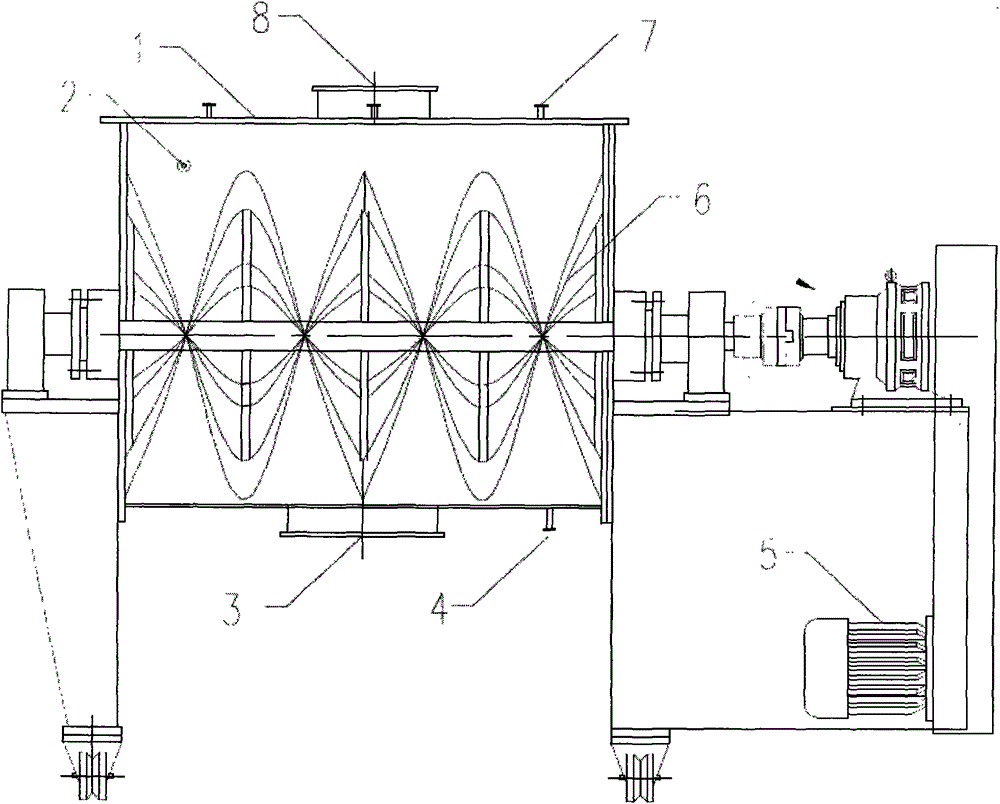

Embodiment example 1

[0017] A method for preventing sodium thiocyanate agglomeration, comprising the following steps: (1) Open the mixing cooler 1, feed the cooling water inlet 4 into 12°C circulating cooling water, start the stirring motor 5, and confirm that the mixing cooling machine 1 is operating normally ; (2) Open the feed port 8 and put in the dried product, at this time the product temperature is 60°C; (3) When the feed amount reaches 1 / 3 of the volume of the mixing cooler 1, add anti-caking through the feed port 7 (4) Continue to add the product, when the product accounts for 3 / 4 of the volume of the mixing and cooling machine 1, stop feeding; (5) Stir the product and the anti-caking agent through the stirring impeller 6 and then mix the product and the anti-caking agent in the mixing and cooling machine 1 Internally cool to normal temperature, open the discharge port 3 to discharge the material, and obtain the anti-caking product; (6) Cooling water outlet 2 releases cooling water, and tu...

Embodiment example 2

[0020] A method for preventing sodium thiocyanate from agglomerating, comprising the following steps: (1) Open the mixing cooler 1, feed the cooling water inlet 4 into 15°C circulating cooling water, start the stirring motor 5, and confirm that the mixing cooling machine 1 is operating normally ; (2) Open the feed port 8 and put in the dried product, at this time the product temperature is 70°C; (3) When the feed amount reaches 1 / 3 of the volume of the mixing cooler 1, add anti-caking through the feed port 7 (4) Continue to add the product, when the product accounts for 3 / 4 of the volume of the mixing and cooling machine 1, stop feeding; (5) Stir the product and the anti-caking agent through the stirring impeller 6 and then mix the product and the anti-caking agent in the mixing and cooling machine 1 Internally cool to normal temperature, open the discharge port 3 to discharge the material, and obtain the anti-caking product; (6) Cooling water outlet 2 releases cooling water, a...

Embodiment example 3

[0023] A method for preventing the formation of sodium thiocyanate, comprising the following steps: (1) Open the mixing cooler 1, feed the cooling water inlet 4 into 17°C circulating cooling water, start the stirring motor 5, and confirm that the mixing cooling machine 1 is operating normally ; (2) Open the feed port 8 and put in the dried product, at this time the product temperature is 75°C; (3) When the feed amount reaches 1 / 3 of the volume of the mixing cooler 1, add anti-caking through the feed port 7 (4) Continue to add the product, when the product accounts for 3 / 4 of the volume of the mixing and cooling machine 1, stop feeding; (5) Stir the product and the anti-caking agent through the stirring impeller 6 and then mix the product and the anti-caking agent in the mixing and cooling machine 1 Internally cool to normal temperature, open the discharge port 3 to discharge the material, and obtain the anti-caking product; (6) Cooling water outlet 2 releases cooling water, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com