A method for pyrolysis and gasification treatment of garbage in a tube-type furnace for rolling gear bars

A technology of pyrolysis gasification and treatment method, applied in combustion methods, incinerators, lighting and heating equipment, etc., can solve the problems of insignificant cutting ability effect, traditional grate form, difficult installation by workers, etc., and achieves aggravating instability. , the effect is obvious, the structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

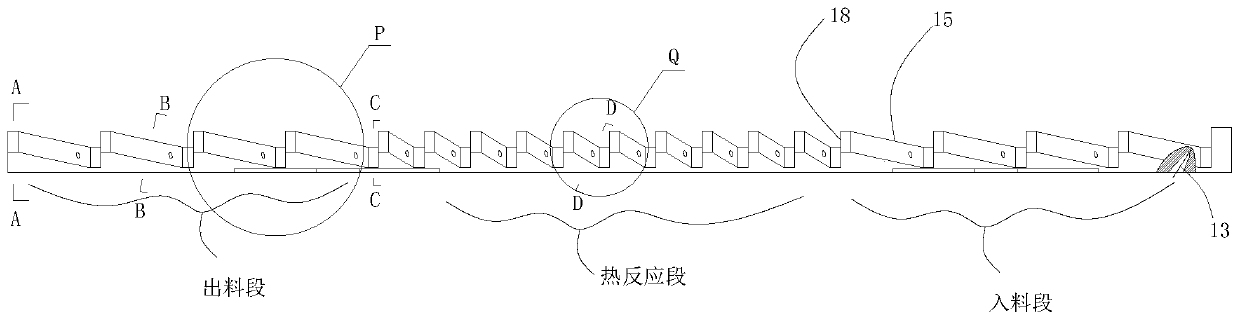

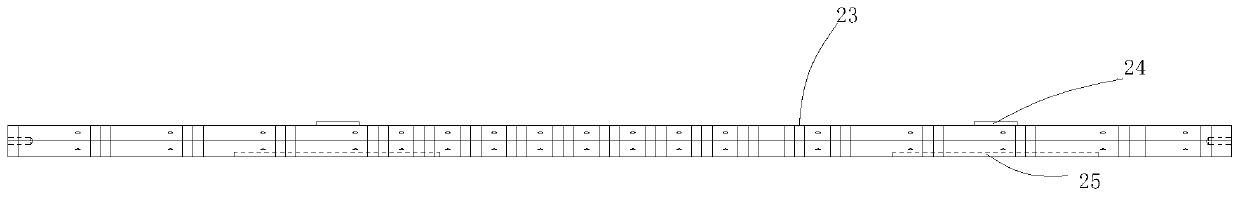

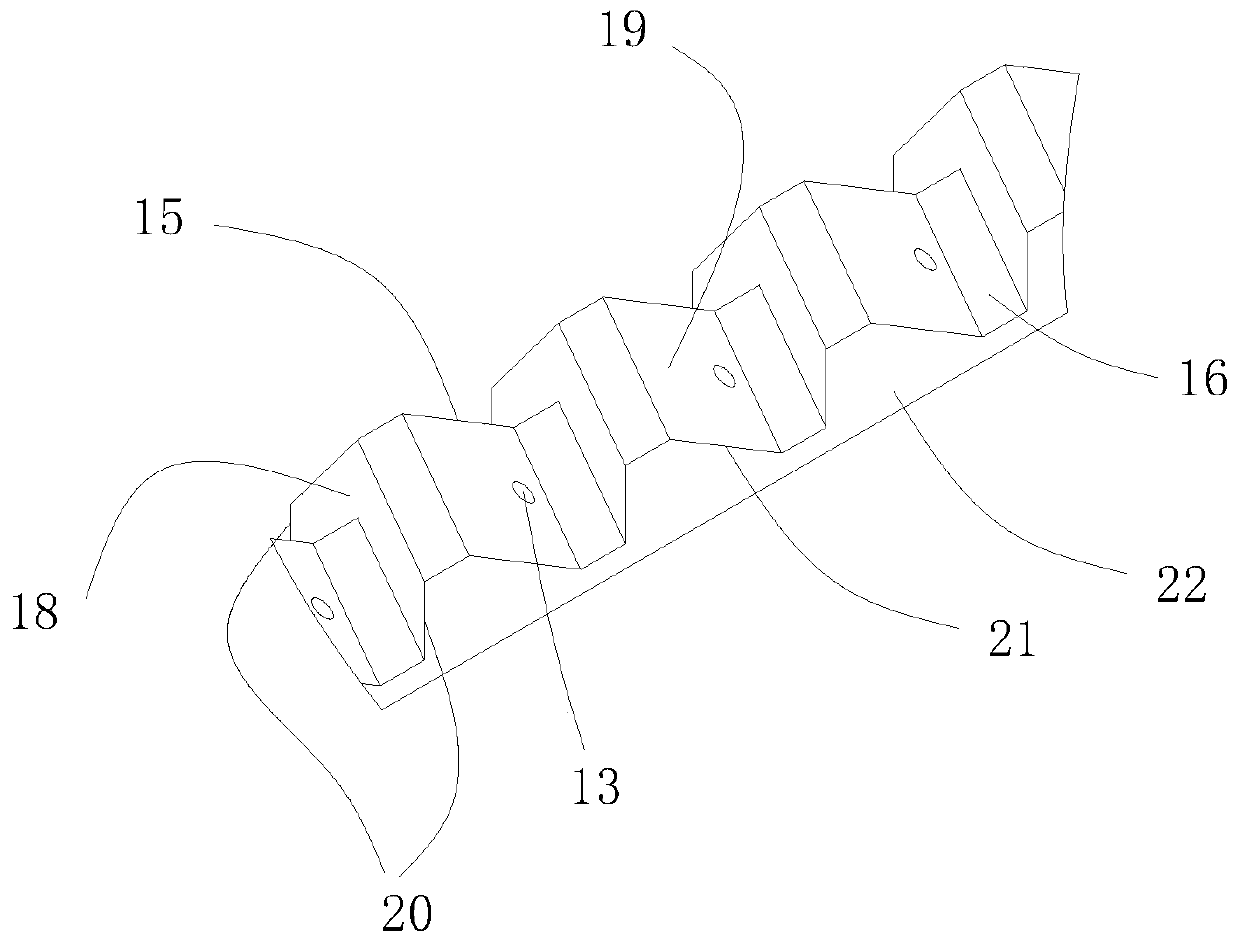

[0054] A method for pyrolysis and gasification treatment of rubbish in a tube-type furnace for gear-rubbing bars, including a tube-type furnace for gear-rubbing bars, see Figure 13-Figure 16 , which is a tooth rubbing furnace bar tube furnace, the tooth rubbing furnace bar tube furnace includes a working base plate, a support frame is arranged at both longitudinal ends of the working base plate, a thermal reaction tube is arranged between the two support frames and a heat reaction tube is used for heat reaction Tube-heated heating furnace, the two ends of the thermal reaction tube are supported on the support frame, the thermal reaction tube can be installed in a forward-inclined and reverse-inclined or horizontal structure, and the state of the pushing motion can be changed. The heating furnace is fixed on the working base plate, the nozzles at both ends of the thermal reaction tube are sealed by sealing fixed end caps, the feed end of the thermal reaction tube is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com