High-explosion-heat aluminium-containing explosive and preparation method thereof

An explosive and high-explosive technology is applied in the field of high-explosive heat aluminum-containing explosives and their preparation, which can solve the problems of poor preparation technology of aluminum-containing explosives, and achieve the effect of improving the explosive heat and good preparation technology of the explosives.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

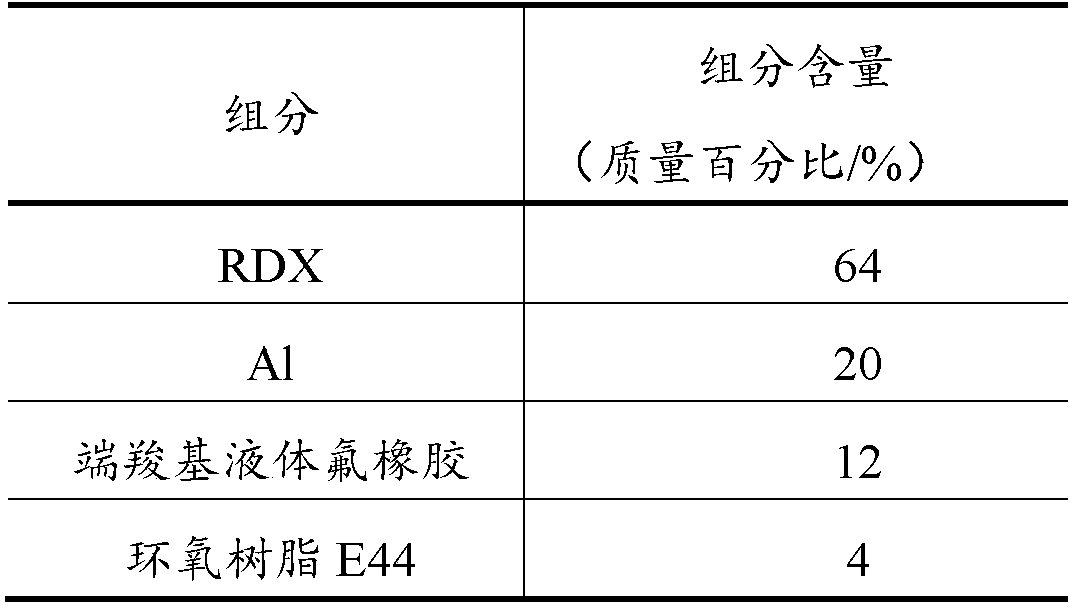

[0023] 一种高爆热含铝炸药,配方参见表1。

[0024] 表1实施例1的高爆热含铝炸药配方

[0025]

[0026] 上述高爆热含铝炸药的制备方法包括以下步骤:

[0027] 步骤(1):按照表1的配方称取原料;

[0028] 步骤(2):将端羧基液体氟橡胶用丙酮溶剂进行搅拌溶解,两者的质量比为1:1;

[0029] 步骤(3):将Al、RDX分别加入到液体氟橡胶中,搅拌混合均匀。

[0030] 步骤(4):将固化剂环氧树脂E44加入到混合物料中,搅拌均匀。

[0031] 步骤(5):将制备的物料用真空浇注的方式装入模具中,脱除料浆中夹带的丙酮溶剂及少量空气,然后放入65℃高温烘箱中加热固化成型。

[0032] 对制得的产品进行性能测试,测试结果如下:

[0033] 本发明实施例制备的含铝炸药爆热6845kJ / kg,与采用HTPB粘结剂的相同炸药配方PBXN-109爆热6430kJ / kg相比,本发明制备的含铝炸药爆热增加了6.45%。

Embodiment 2

[0035] 一种高爆热含铝炸药,配方参见表2。

[0036] 表2实施例2的高爆热含铝炸药配方

[0037]

[0038] 上述高爆热含铝炸药的制备方法包括以下步骤:

[0039] 步骤(1):按照表2的配方称取原料;

[0040] 步骤(2):将端羟基液体氟橡胶用丙酮溶剂进行搅拌溶解,两者的质量比为1:1;

[0041] 步骤(3):将Al、HMX分别加入到液体氟橡胶中,搅拌混合均匀。

[0042] 步骤(4):将固化剂HDI三聚体加入到混合物料中,搅拌混合均匀。

[0043] 步骤(5):将制备的物料用真空浇注的方式装入模具中,脱除料浆中夹带的丙酮溶剂及少量空气,然后放入65℃高温烘箱中加热固化成型。

[0044] 对制得的产品进行性能测试,测试结果如下:

[0045] 本发明实施例制备的含铝炸药爆热实测7420kJ / kg,与采用HTPB粘结剂的相同炸药配方的爆热7130kJ / kg相比,本发明制备的含铝炸药爆热增加了4.1%。

Embodiment 3

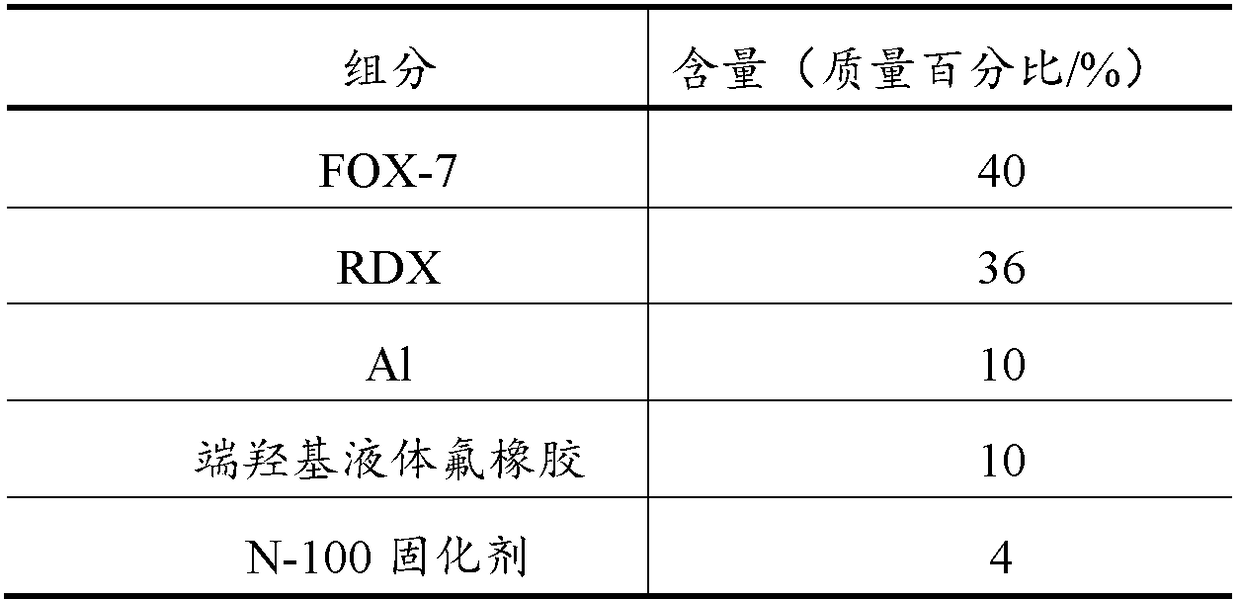

[0047] 一种高爆热含铝炸药,配方参见表3。

[0048] 表3实施例3的高爆热含铝炸药配方

[0049]

[0050] 上述高爆热含铝炸药的制备方法包括以下步骤:

[0051] 步骤(1):按照表3的配方称取原料;

[0052] 步骤(2):将端羟基液体氟橡胶用丙酮溶剂进行搅拌溶解,两者的质量比为1:1;

[0053] 步骤(3):将Al、FOX-7、RDX分别加入到液体氟橡胶中,搅拌混合均匀。

[0054] 步骤(4):将固化剂N-100加入到混合物料中,搅拌均匀。

[0055] 步骤(5):将制备的物料用真空浇注的方式装入模具中,脱除料浆中夹带的丙酮溶剂及少量空气,然后放入65℃高温烘箱中加热固化成型。

[0056] 对制得的产品进行性能测试,测试结果如下:

[0057] 本发明实施例制备的含铝炸药爆热为6310kJ / kg。

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com