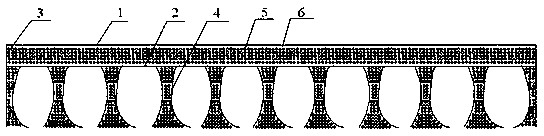

Continuous glass fiber reinforced polyurethane composite material walking board and preparation method thereof

A glass fiber and composite material technology, used in buildings, roads, bridges, etc., can solve the problem that the walking board cannot be processed twice, and achieve the effects of light weight, convenient installation and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The above-mentioned preparation method of a continuous glass fiber reinforced polyurethane composite walking board specifically includes the following steps.

[0034] A. Place the continuous glass fiber on the creel of the yarn guide felt device, lead it out through the yarn guide hole, and pass through the preforming device, the glue injection box of the glue injection device, and the mold of the curing molding device in sequence according to the structure of the walking board , a hydraulic tractor that is introduced into the traction unit.

[0035] B. Place the reinforcing felt on the reel of the yarn guiding felt device, lead it out through the felt guiding plate, pass through the preforming device, the glue injection box of the glue injection device, and the mold of the curing molding device in sequence according to the structure of the walking board, and then introduce to the hydraulic tractor of the traction unit.

[0036] C. Connect the glue injection machine of t...

Embodiment 1

[0042] The walking board in this embodiment is prepared from the following components in parts by weight: 50 parts of continuous glass fiber, 20 parts of reinforcing mat, and 25 parts of polyurethane resin. Among them, the continuous glass fiber adopts alkali-free direct yarn with a number of 9600tex, the reinforcing mat is a seam mat, the polyurethane resin is composed of isocyanate component A and polyether component B, and the mass ratio of component A to component B is 105: 100.

[0043] This example was prepared using the following steps.

[0044] A. Place the continuous glass fiber on the creel of the yarn guide felt device, lead it out through the yarn guide hole, and pass through the preforming device, the glue injection box of the glue injection device, and the mold of the curing molding device in sequence according to the structure of the walking board , a hydraulic tractor that is introduced into the traction unit.

[0045] B. Place the reinforcing felt on the ree...

Embodiment 2

[0051] The walking board in this embodiment is prepared from the following components in parts by weight: 70 parts of continuous glass fiber, 30 parts of reinforcing mat, and 18 parts of polyurethane resin. Among them, the continuous glass fiber adopts alkali-free direct yarn with a number of 4400tex, the reinforcing mat is multi-axial cloth, the polyurethane resin is composed of isocyanate component A and polyether component B, and the mass ratio of component A to component B is 125 : 100.

[0052] This example was prepared using the following steps.

[0053] A. Place the continuous glass fiber on the creel of the yarn guide felt device, lead it out through the yarn guide hole, and pass through the preforming device, the glue injection box of the glue injection device, and the mold of the curing molding device in sequence according to the structure of the walking board , a hydraulic tractor that is introduced into the traction unit.

[0054] B. Place the reinforcing felt on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com