Electric wine decanter

A decanter, electric technology, applied in the field of wine, can solve the problems of increasing the volume of the decanter, complex driving structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

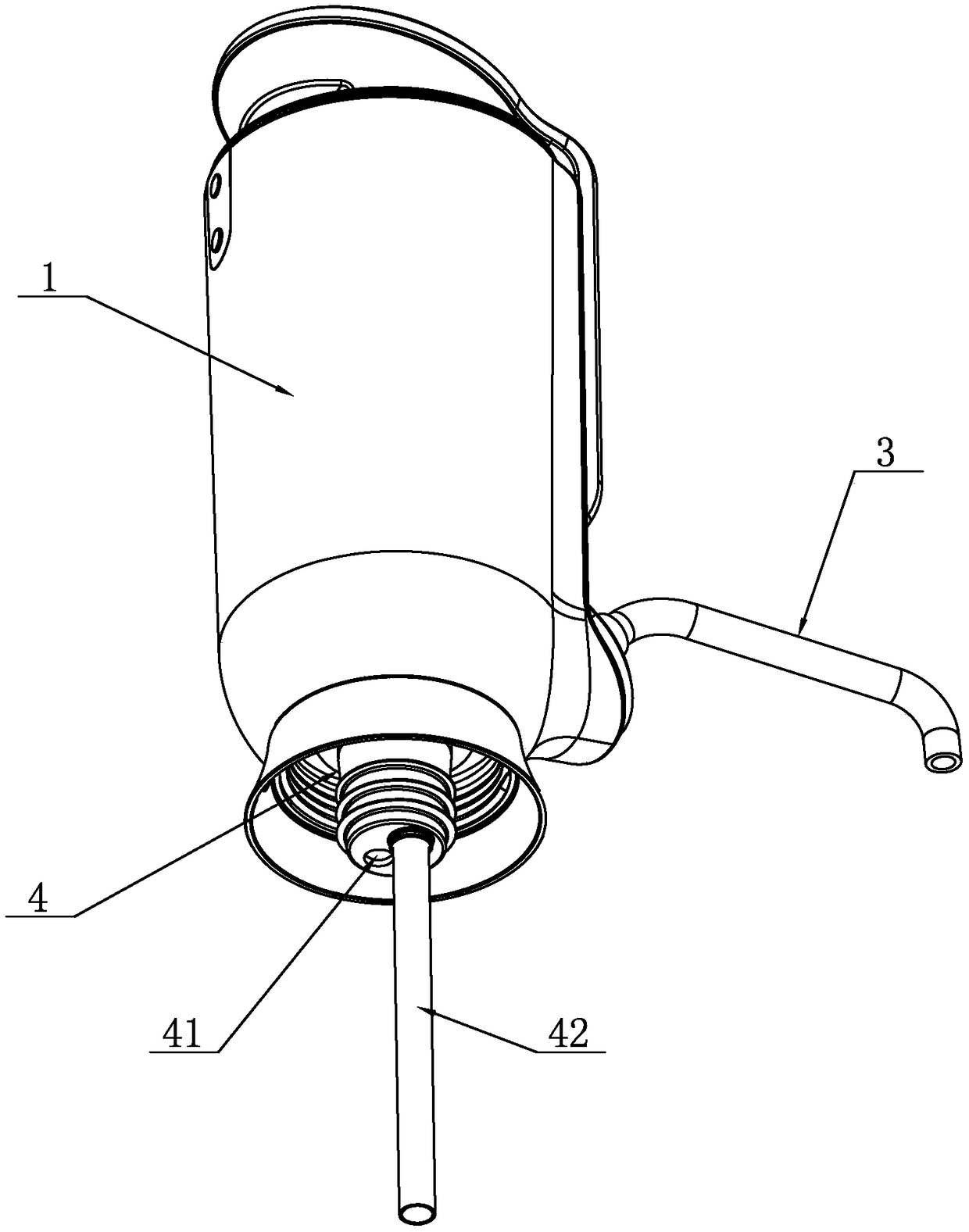

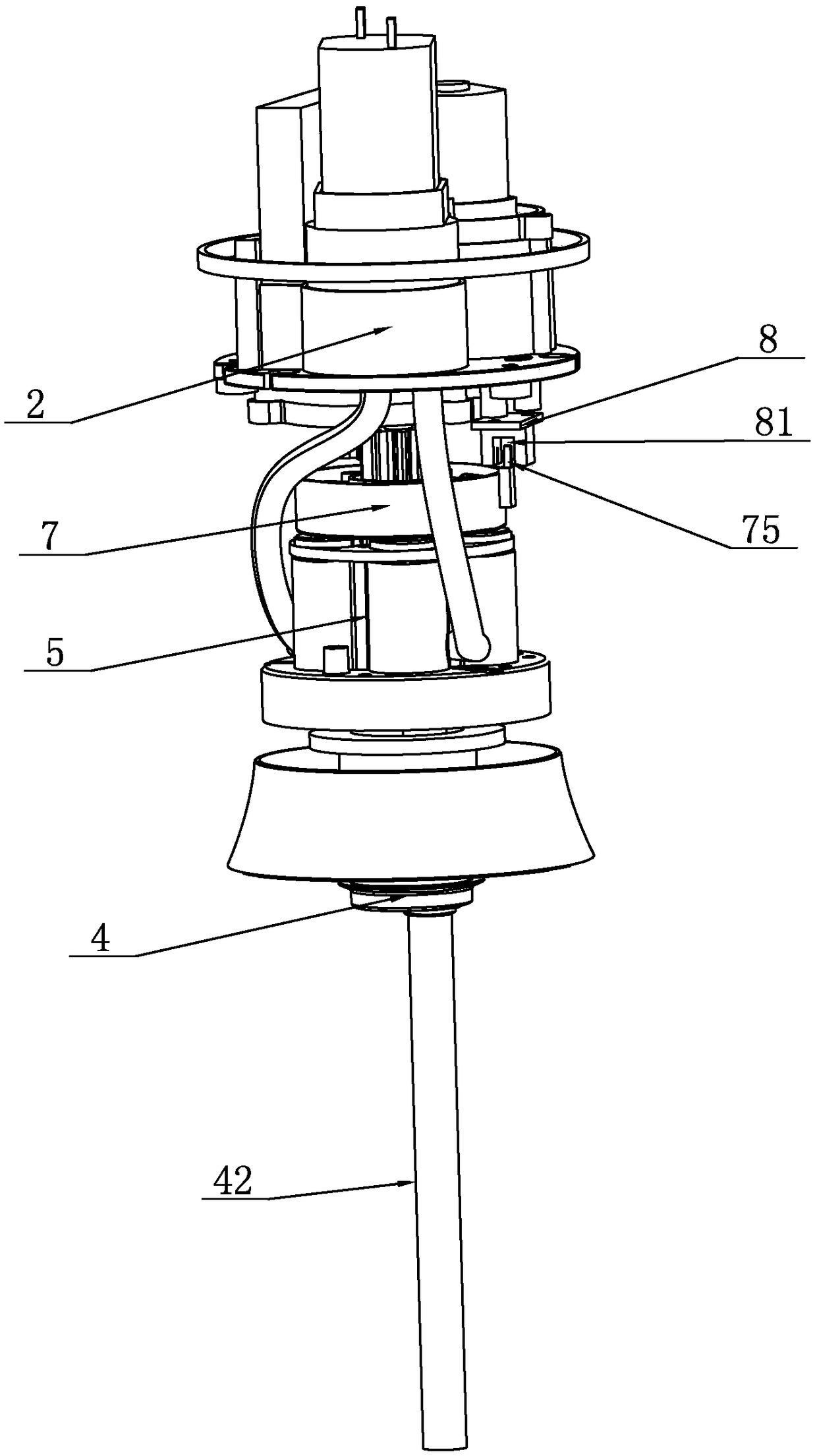

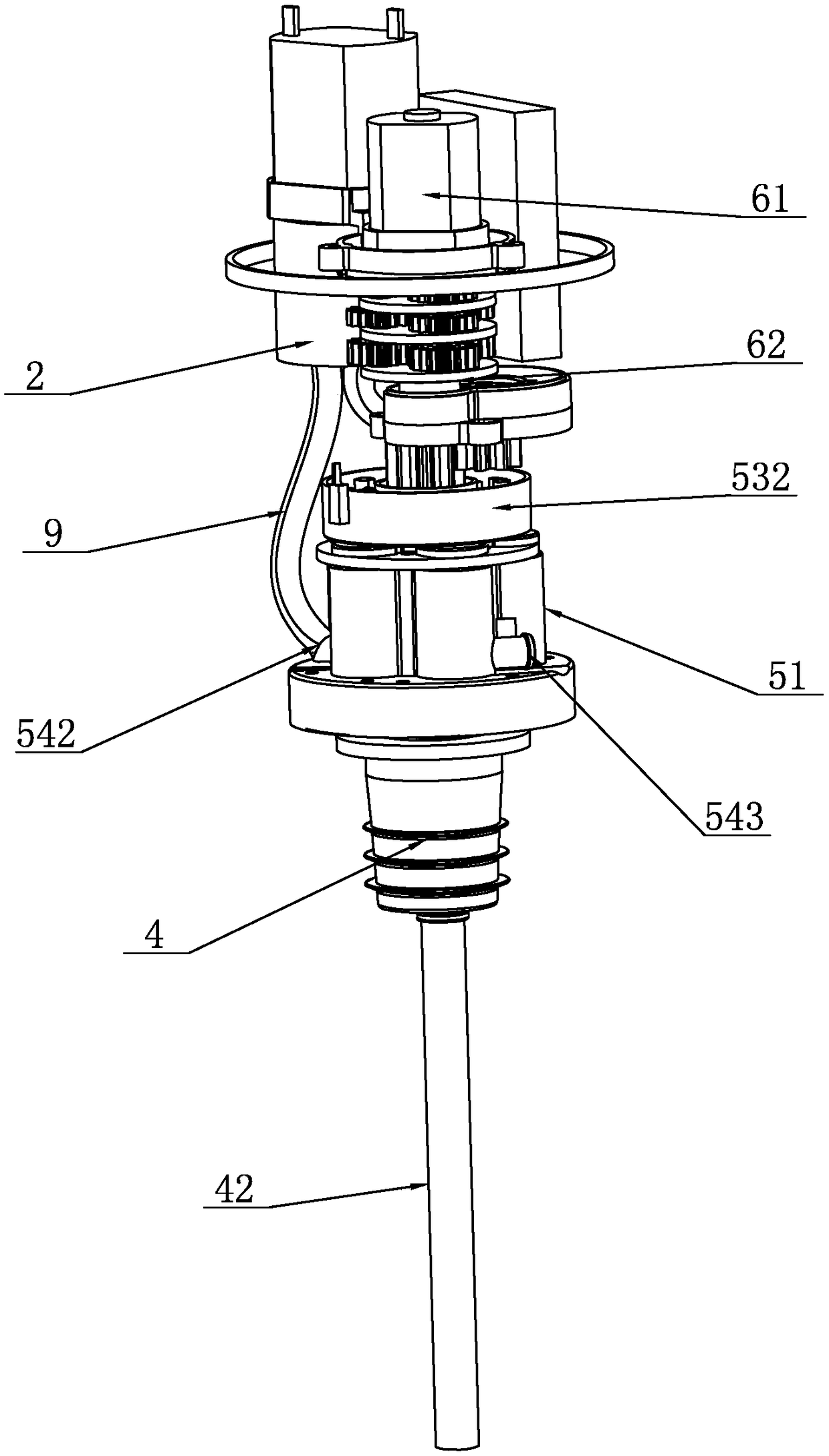

[0038] like Figure 1-Figure 14 As shown, an electric decanter includes a housing 1, an air pump 2 is provided inside the housing 1, a wine outlet pipe 3 is connected to the housing 1, and a base for fixing the wine decanter at the opening of the wine container is provided at the bottom of the housing 1 4. The base 4 is provided with a vent hole 41 communicating with the air in the wine liquid container and a wine guide tube 42 extending into the wine liquid container. The shell 1 is also provided with a reversing valve 5 for controlling the air path of the air pump 2 and a control switch. The drive mechanism that operates toward the valve 5. The reversing valve 5 includes a valve body 51 and a valve seat 52 installed at the bottom of the valve body 51. The valve body 51 is provided with a valve cavity, and the valve cavity includes a first valve cavity 511, a second valve cavity 512, the third valve cavity 513, the fourth valve cavity 514 and the fifth valve cavity 515, the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com