Pile driver for architectural engineering

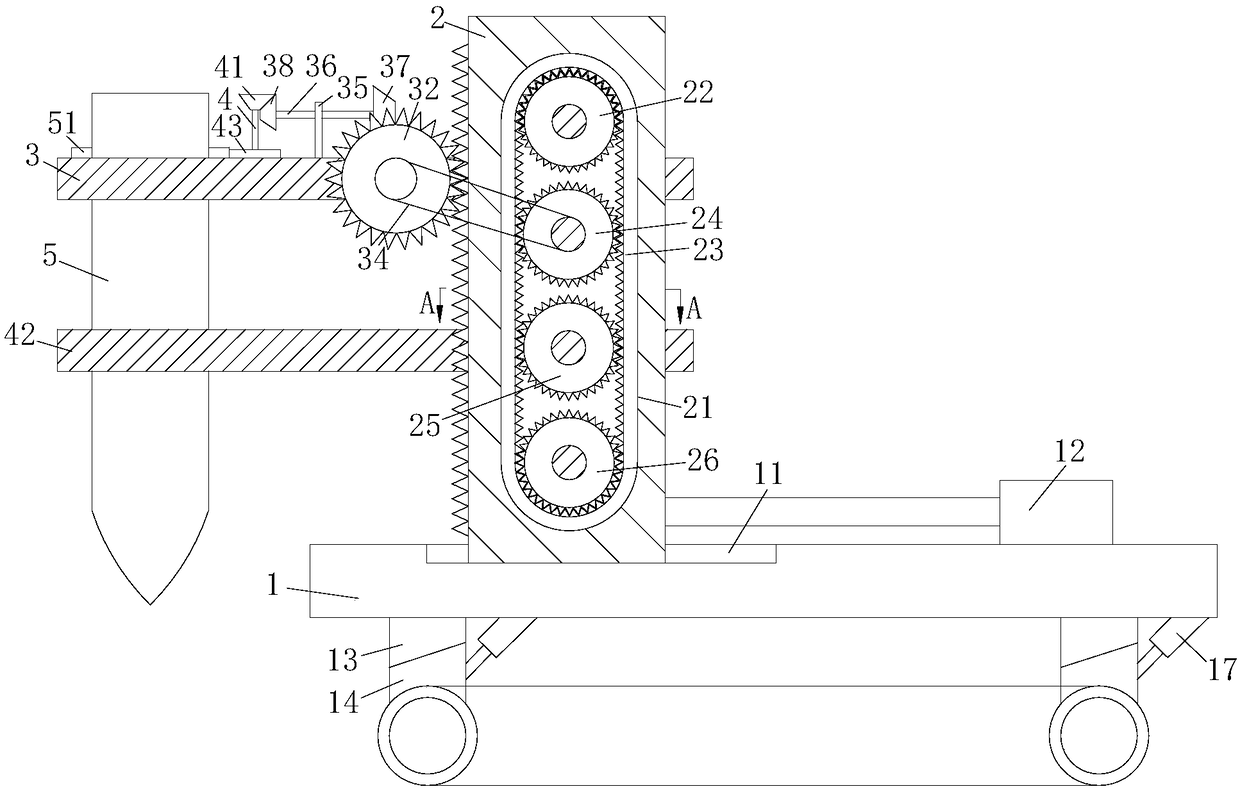

A construction engineering and piling machine technology, which is applied in construction, foundation structure engineering, sheet pile walls, etc., can solve the problems of piling heads stuck in the soil, low piling efficiency, and piling head damage, so as to prevent the soil from sticking and speed up piling The effect of high speed and convenient piling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

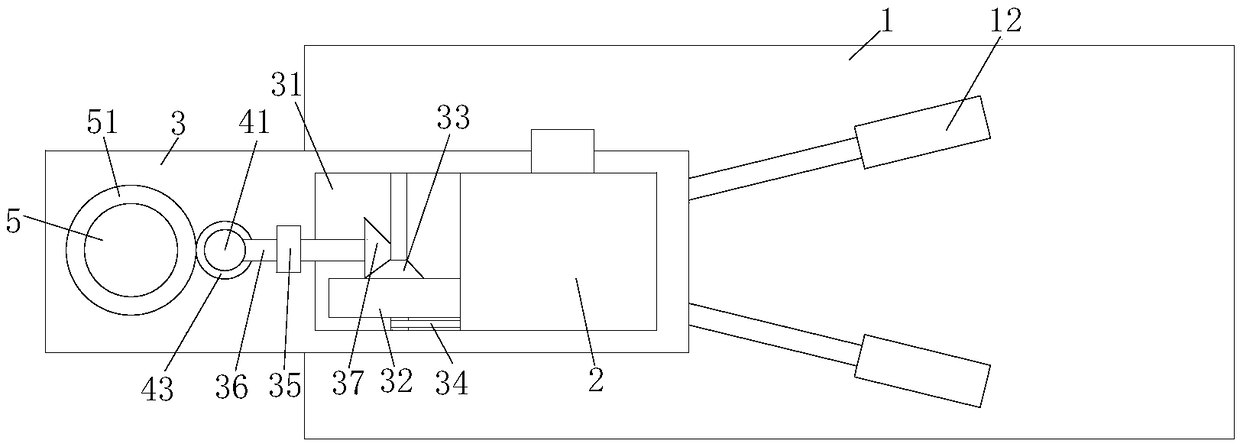

Method used

Image

Examples

Embodiment approach

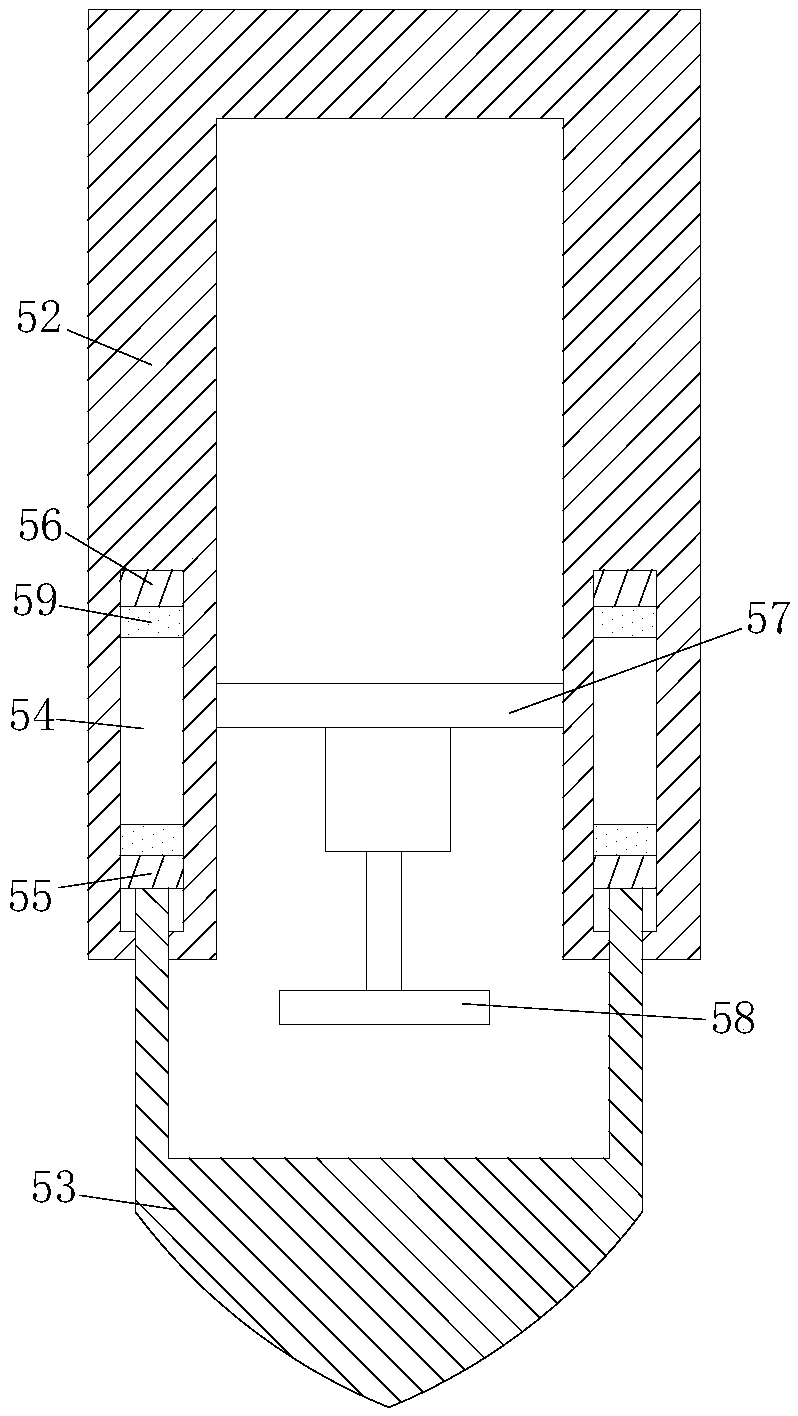

[0027] As an embodiment of the present invention, the piling column 5 is divided into two parts: a column body 52 and a piling head 53; the column body 52 is hollow, and the lower end of the column body 52 is provided with a third opening 54; The three openings 54 are ring-shaped design; the upper end of the piling head 53 penetrates into the third opening 54 and is fixedly connected with a first extruding block 55, and the first extruding block 55 slides in the third opening 54; on the third opening 54 The inner wall is fixed with a second extruding block 56; the first extruding block 55 and the second extruding block 56 are all ring-shaped; the inner wall of the cylinder 52 is fixed with a bearing plate 57; the object bearing plate 57 Circular design, and the lower surface of the bearing plate 57 is fixedly connected with a cylinder, which communicates with the third opening 54; the protruding end of the cylinder is fixedly connected with a striking plate 58; the piling head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com