Kitchen waste treatment device

A treatment device and kitchen waste technology, applied in the field of machinery, can solve the problems of waste corruption, power consumption, water waste, etc., and achieve the effect of keeping clean and hygienic, long service life, and eliminating odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

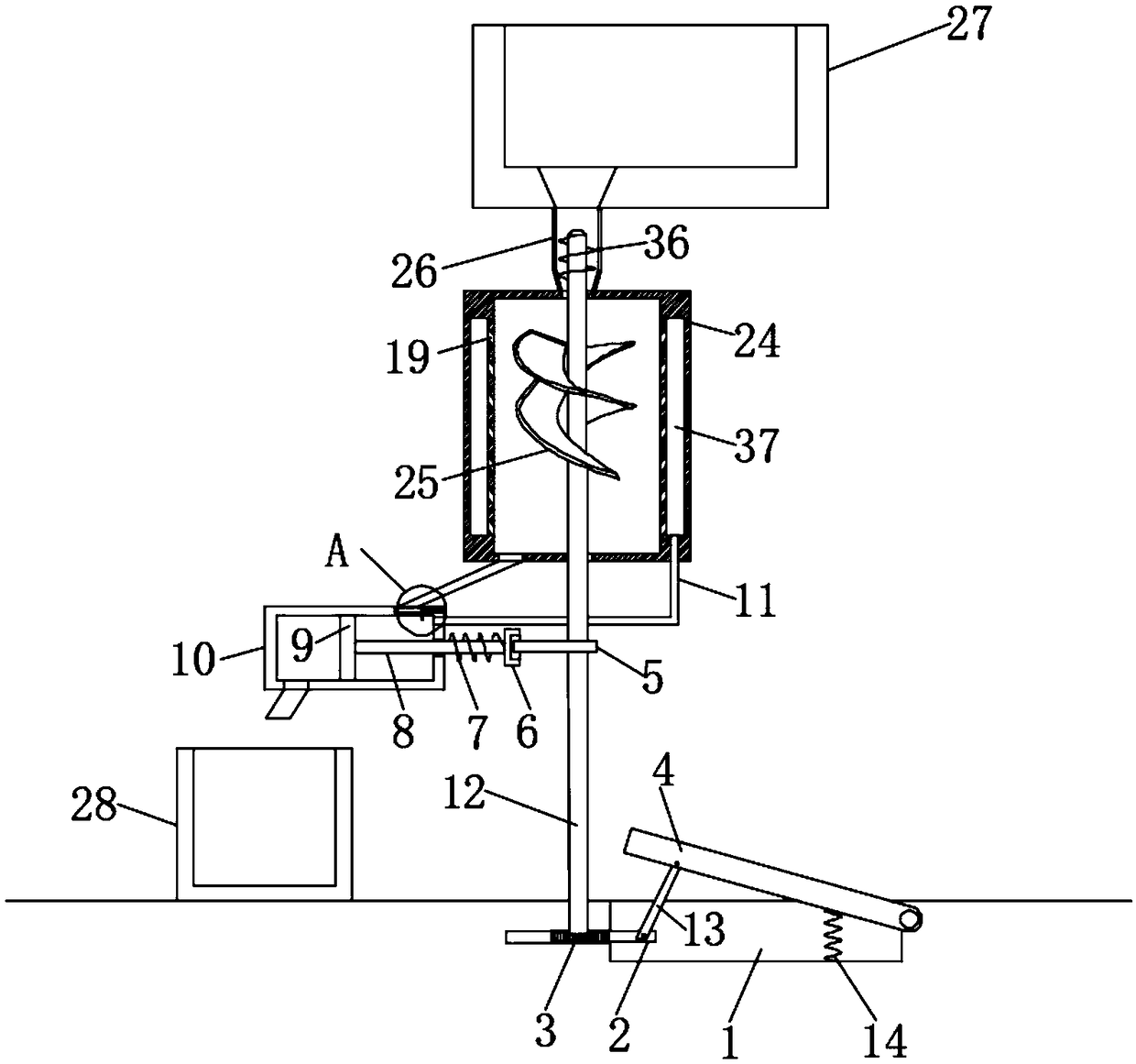

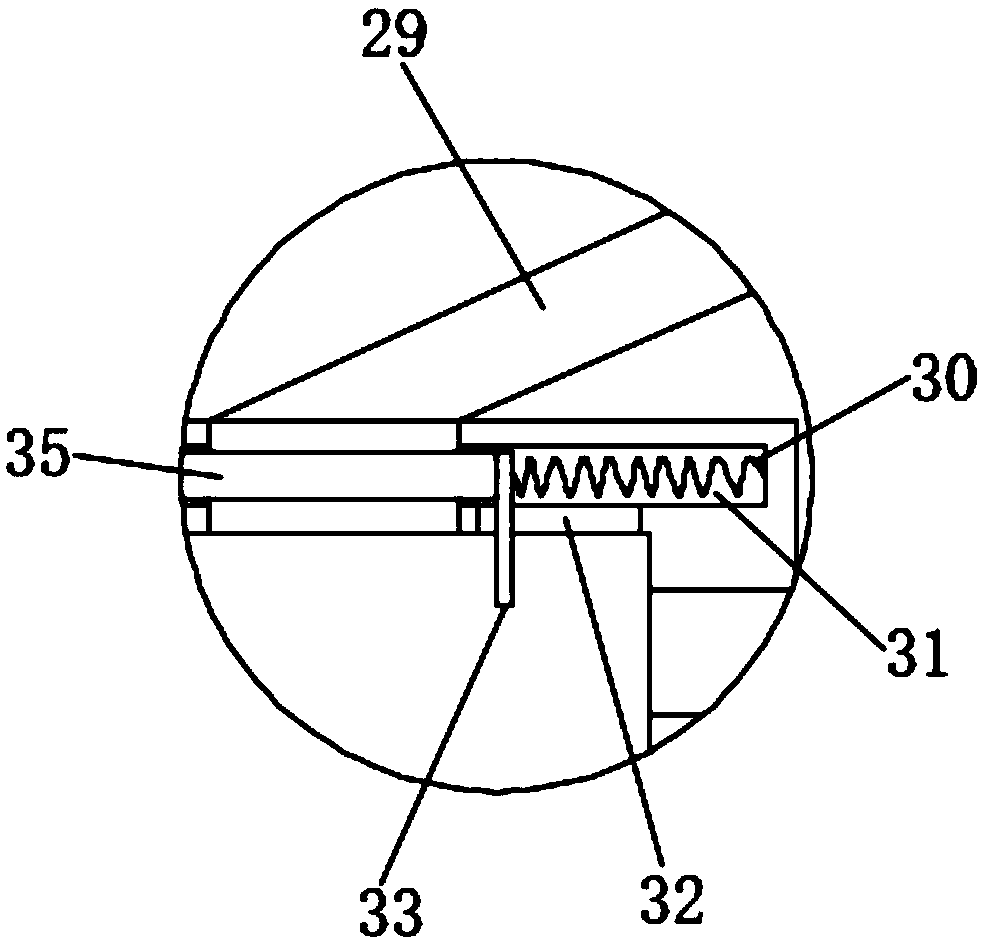

[0021] refer to Figure 1-2 , a kitchen waste disposal device, including a groove 1 arranged on the ground and a cleaning pool 27 above the ground, the inner wall of the groove 1 is connected with a pedal 4 in rotation, and the pedal 4 is elastically connected to the groove 1 through a first spring 14 The inner bottom of the groove 1 is provided with a chute on the inner wall of the groove 1, and the rack 2 is slidably connected to the chute, and the end of the rack 2 located in the groove 1 is rotatably connected to a connecting rod 13, and the end of the connecting rod 13 is far away from the rack 2 Rotationally connected to the lower end of the pedal 4, the inner bottom of the chute is rotatably connected to the gear 3 meshing with the rack 2, the part of the wall below the cleaning pool 27 is fixedly connected to the crushing barrel 24, and the crushing barrel 24 is coaxial along the vertical direction A transmission shaft 12 is connected through rotation, and a discharge ...

Embodiment 2

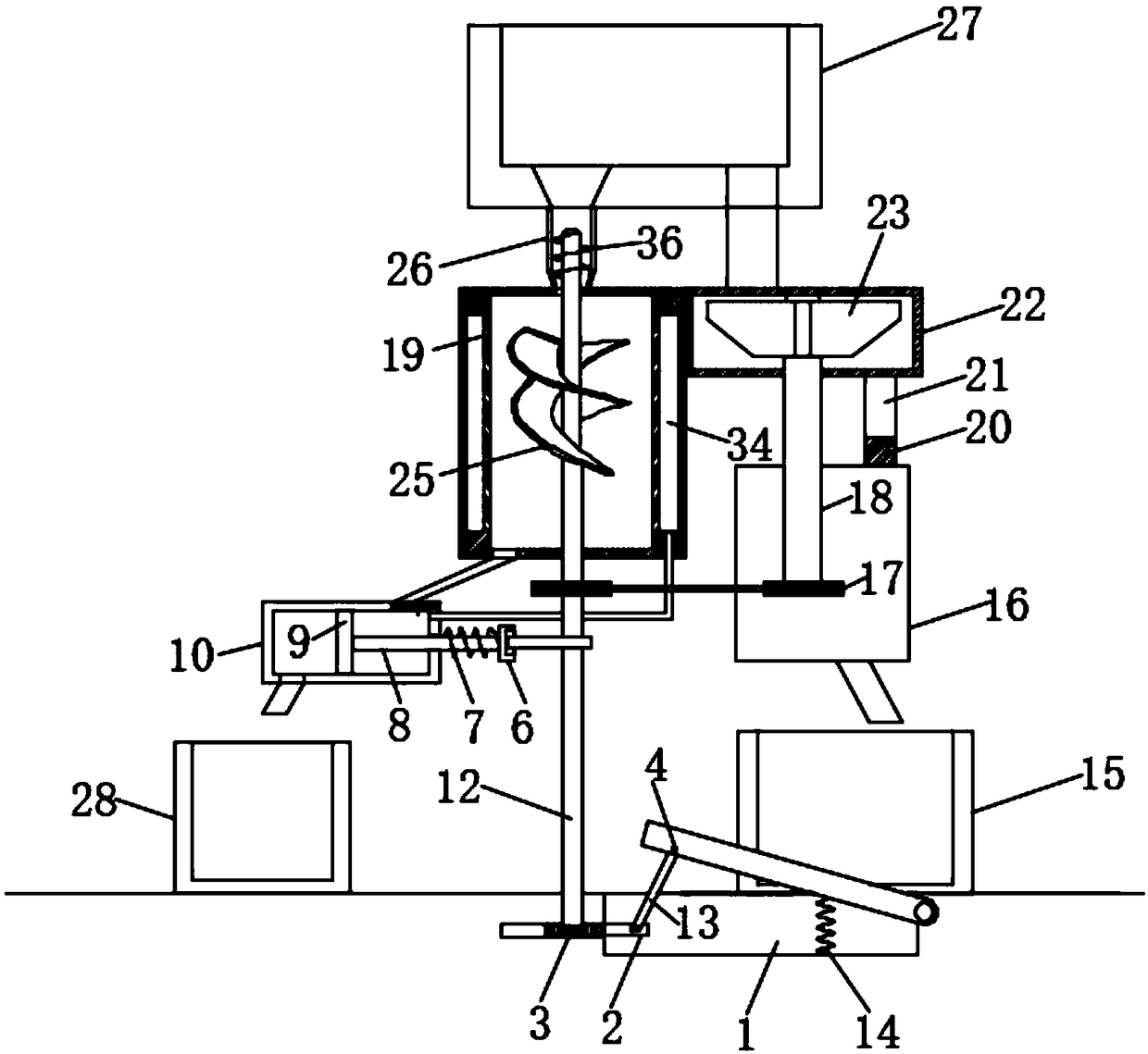

[0026]The difference from Embodiment 1 is that in this embodiment, a pump casing 22 and an impeller 23 arranged in the pump casing 22 are fixedly connected to the side wall of the crushing barrel 24, and the upper end of the pump casing 22 passes through the water delivery pipe and the lower end of the cleaning tank 27. Connected, the part of the wall below the pump casing 22 is fixedly connected with a filter 16. The filter 16 is a common sewage filter device sold on the market, which is well known to those skilled in the art. The lower end of the pump casing 22 passes through the drain pipe 21 and the filter. 16 is connected and the first check valve 20 that only allows water to enter the filter 16 is installed at the connection point. The lower end of the impeller 23 is connected to the rotating shaft 18 through the coaxial transmission. The rotating shaft 18 runs through the inner bottom of the pump casing 22. 17 is connected with transmission shaft 12, and the upper end su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com