A fully automatic kitchen tableware cleaning and garbage disposal device and integrated kitchen

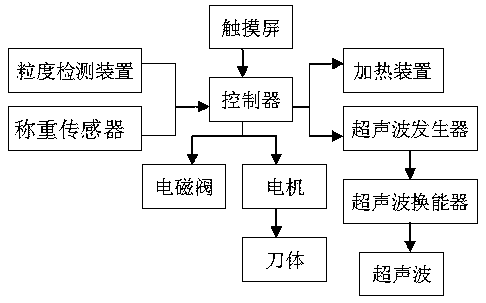

A garbage disposal device and tableware cleaning technology, applied in kitchen cabinets, grain disposal, household utensils, etc., can solve the problems of fine particles that are easily washed into the sewer with water, garbage corruption, motor loss, etc., to increase the effect of garbage crushing , reduce the movement rate, and realize the effect of intelligent control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

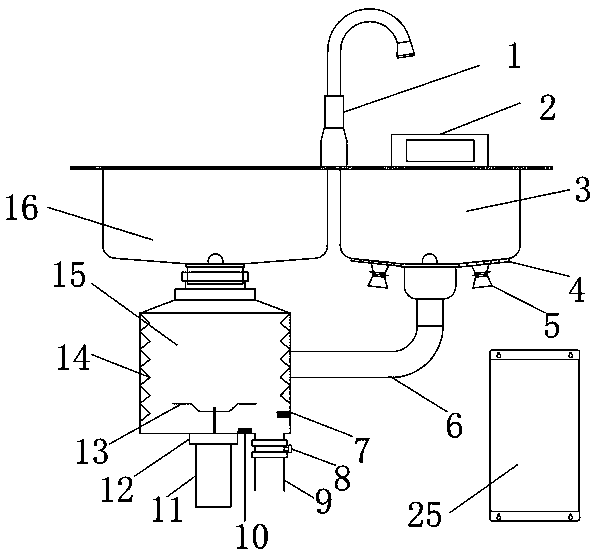

[0044] Such as Figure 4 , 5 As shown, the base 12 of the rubbish crushing device is provided with an inner shaft 20 and an outer shaft 19 running in the opposite direction, and a connecting shaft 21 is arranged between the inner shaft 20 and the outer shaft 19, and the inner shaft 20, the outer shaft 19 and the connecting shaft 21 They are connected by gears 22, the inner shaft 20 is connected with the lower cutter body 17, and the outer shaft 19 is connected with the upper cutter body 18. Through the cooperation of the gear 22, the lower cutter body 17 and the upper cutter body 18 can run in the opposite direction, reducing the amount of rubbish being crushed. The speed of motion in the chamber 15 increases the pulverizing effect, and all the other structures and working processes are the same as in Embodiment 1, so no more details are given.

Embodiment 3

[0046] The same structure as Embodiment 1 is not repeated, as Figure 6 As shown, the base 12 of the rubbish crushing device is provided with a turntable 23 opposite to the direction of rotation of the cutter body 13 for containing the rubbish to be crushed. Added smash effect.

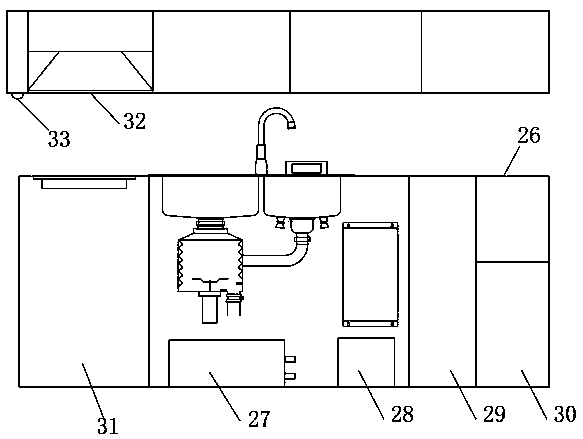

[0047] To sum up, the present invention integrates kitchen appliances, realizes intelligent control, and reduces the floor area of kitchen appliances; realizes ultrasonic cleaning, can reduce the use of detergent, and effectively removes pesticide residues in fruits and vegetables, generally within 3-5 minutes It can remove more than 95% of pesticide residues in the machine, and has a wide range of applications; the garbage crushing device of the present invention can crush leftovers, picked vegetable leaves and roots, garbage after washing dishes and other kitchen waste directly into the sewer, and the crushing effect is good. , The crushed particles are less than 5mm, will not block the sewage, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com