A cup-shaped pre-grouting reinforcement method for full-section curtain grouting

A curtain grouting and pre-grouting technology, which is applied in earthwork drilling, shaft equipment, wellbore lining, etc., can solve the problems of complex construction technology, long construction period, and water gushing plugging legacy, and achieve obvious construction period benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The technical solutions of the present invention will be further described below with reference to the accompanying drawings and specific embodiments.

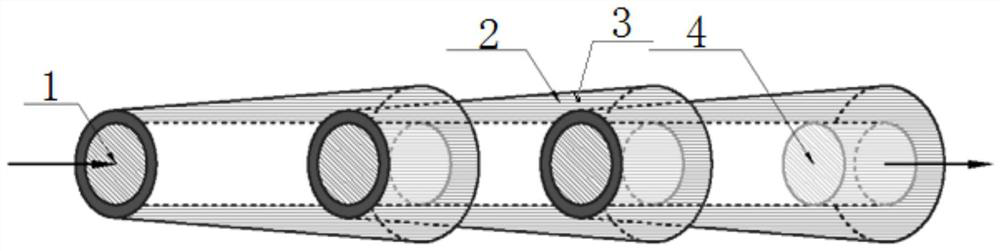

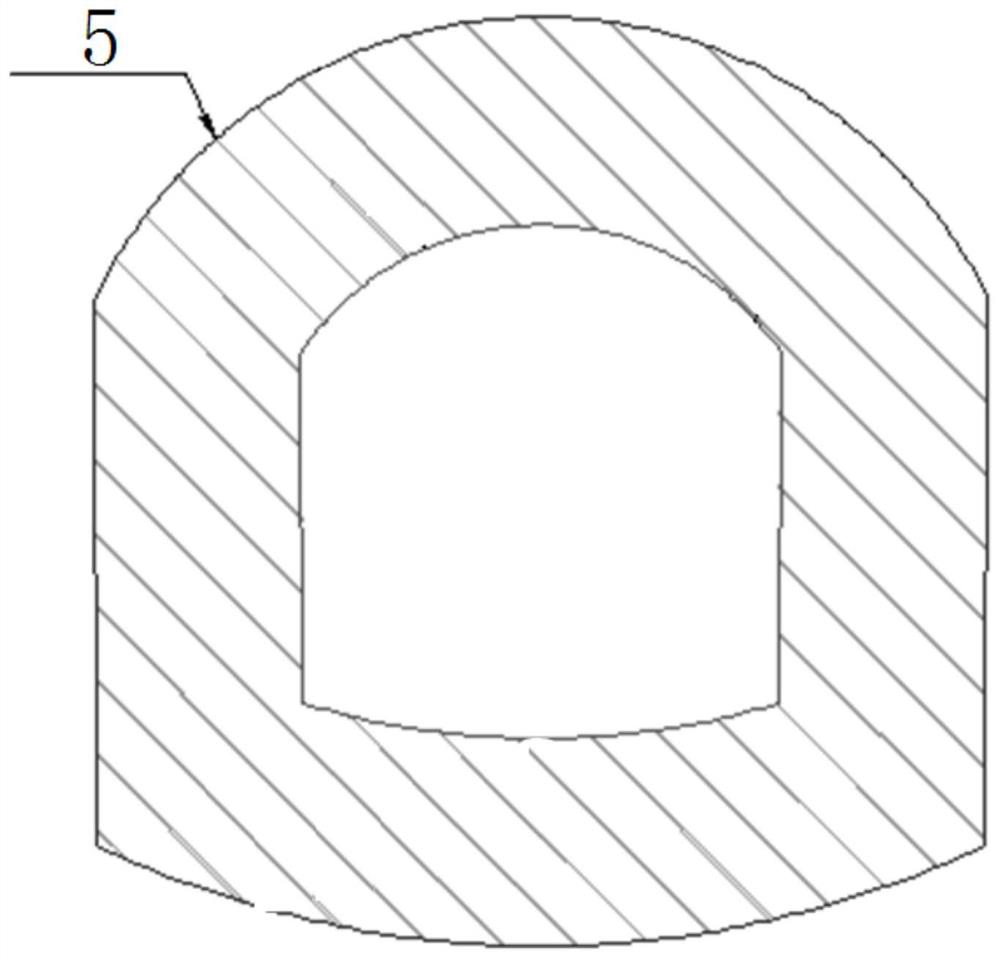

[0077] see Figure 1-Figure 2 , a cup-shaped pre-grouting reinforcement method for full-section curtain grouting, which improves full-section curtain grouting and adopts the concept of cup-shaped pre-grouting reinforcement, that is, through the peripheral curtain 2 (including the arch tube curtain 3) and the central hole hole The water-stop rock plate 4 (the bottom of the cup) formed by bottom grouting forms a cup-shaped three-dimensional water-stop reinforcement ring to solve the two problems of water-stop and collapse prevention for water-rich faults.

[0078] Before entering the fault, a 10m slug-stop rock plate is reserved. The 120° range of the arch is made of advanced pipe shed grouting to form the pipe curtain, and the rest of the surrounding holes are grouted with segmented and backward deep holes to form 360° w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com