Integrated dual-pulse solid engine soft interlayer

A solid motor and double-pulse technology, which is applied in the direction of machines/engines, rocket motor devices, mechanical equipment, etc., can solve problems such as the inability to use large-diameter double-pulse motors, high material density, and large negative mass, and achieve simplified integrated molding process, improving mass ratio, and reducing negative mass effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

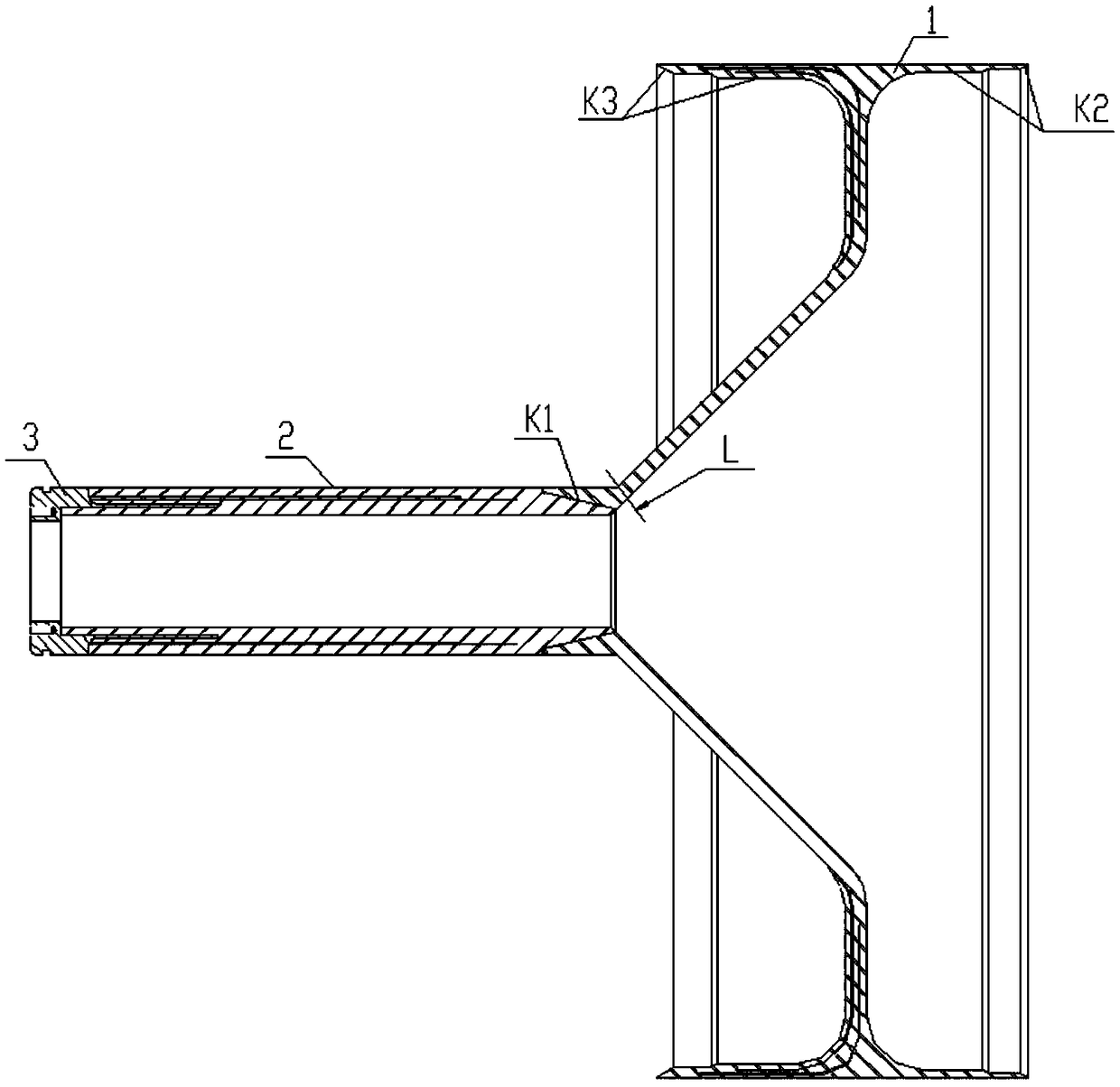

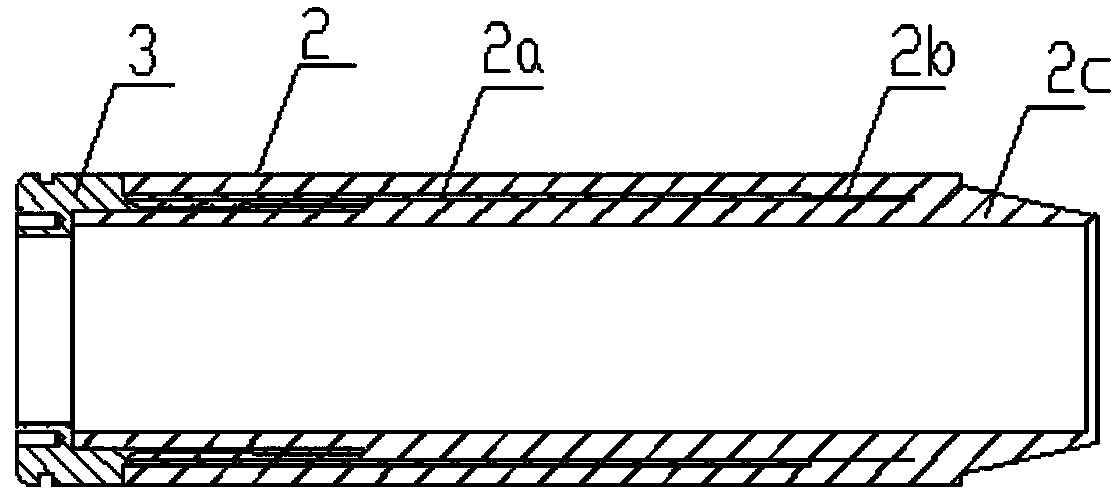

[0027] see figure 1 As shown, the embodiment of the present invention provides an integrated double-pulse solid motor soft barrier, including a cone 1, a sleeve 2 and a connecting sleeve 3:

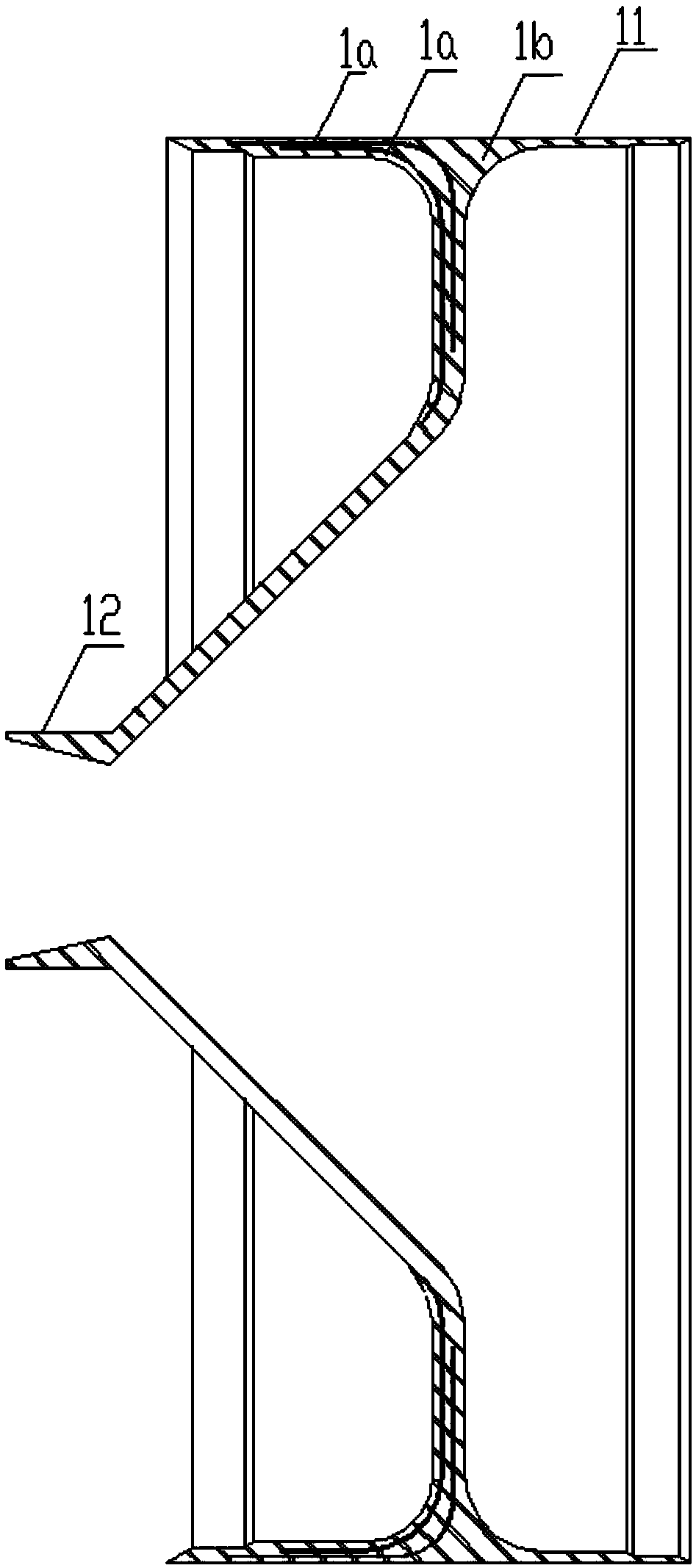

[0028] see figure 2 As shown, the cone 1 includes a first fixing part 11 for fixing with one or two pulse combustion chambers and a second fixing part 12 for fixing with the sleeve 2, and the first fixing part 11 is located on The end of the larger diameter of the cone 1, the second fixing part 12 is located at the smaller end of the cone 1; the cone 1 includes a EPDM layer 1b and a carbon cloth layer 1a, increasing the cone The strength of the cone 1 ensures that the cone 1 is complete under the first pulse working pressure and the cone 1 is not broken from the root of the cone 1 when the second pulse is working, resulting in large pieces of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com