Full-performance test stand for automobile automatic transmission machining oil pump

A technology of automatic transmission and oil pump, applied in the field of auto parts manufacturing, can solve the problems of few test items, low precision and large error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment, technical solution content of the present invention is described further:

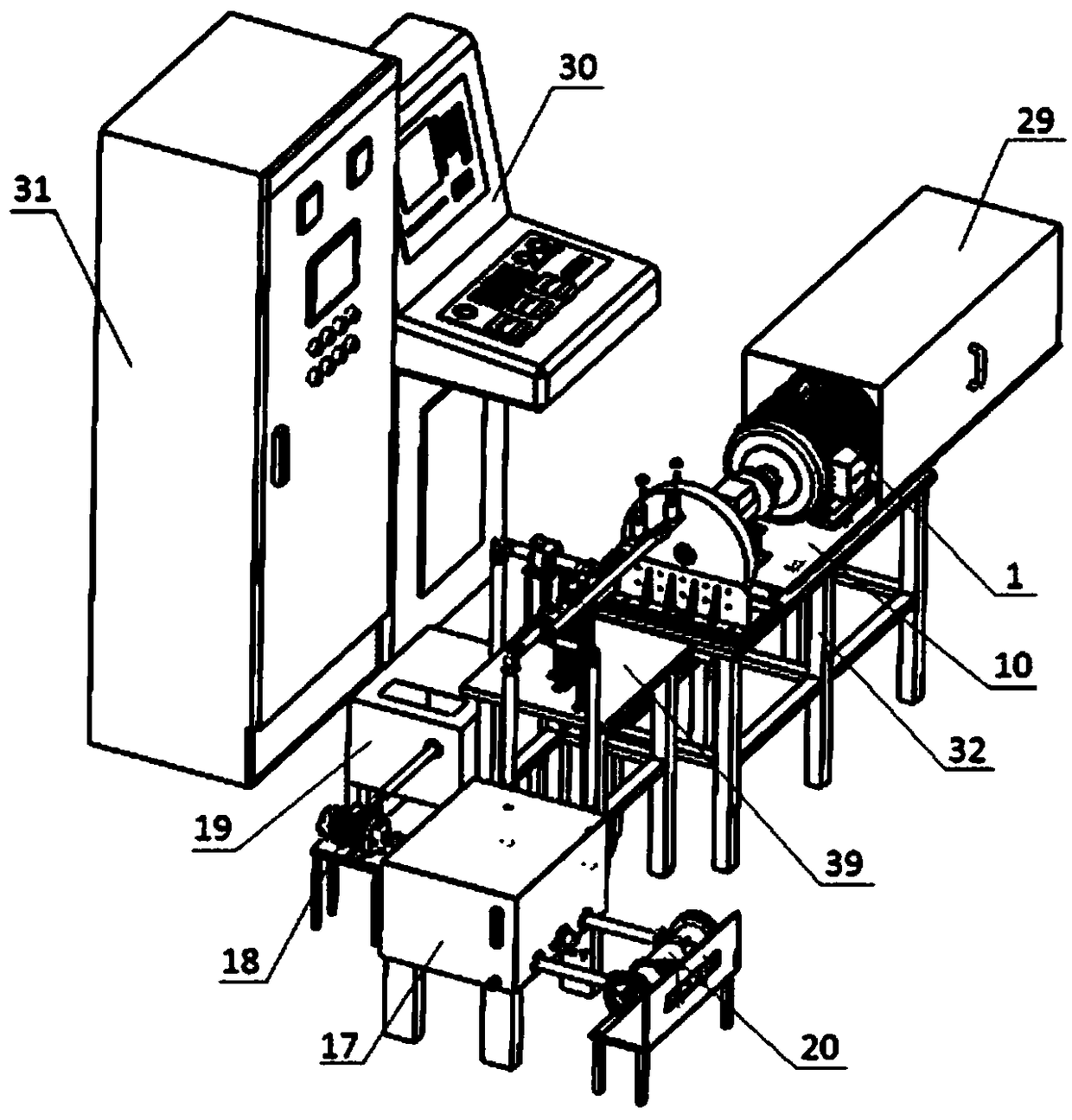

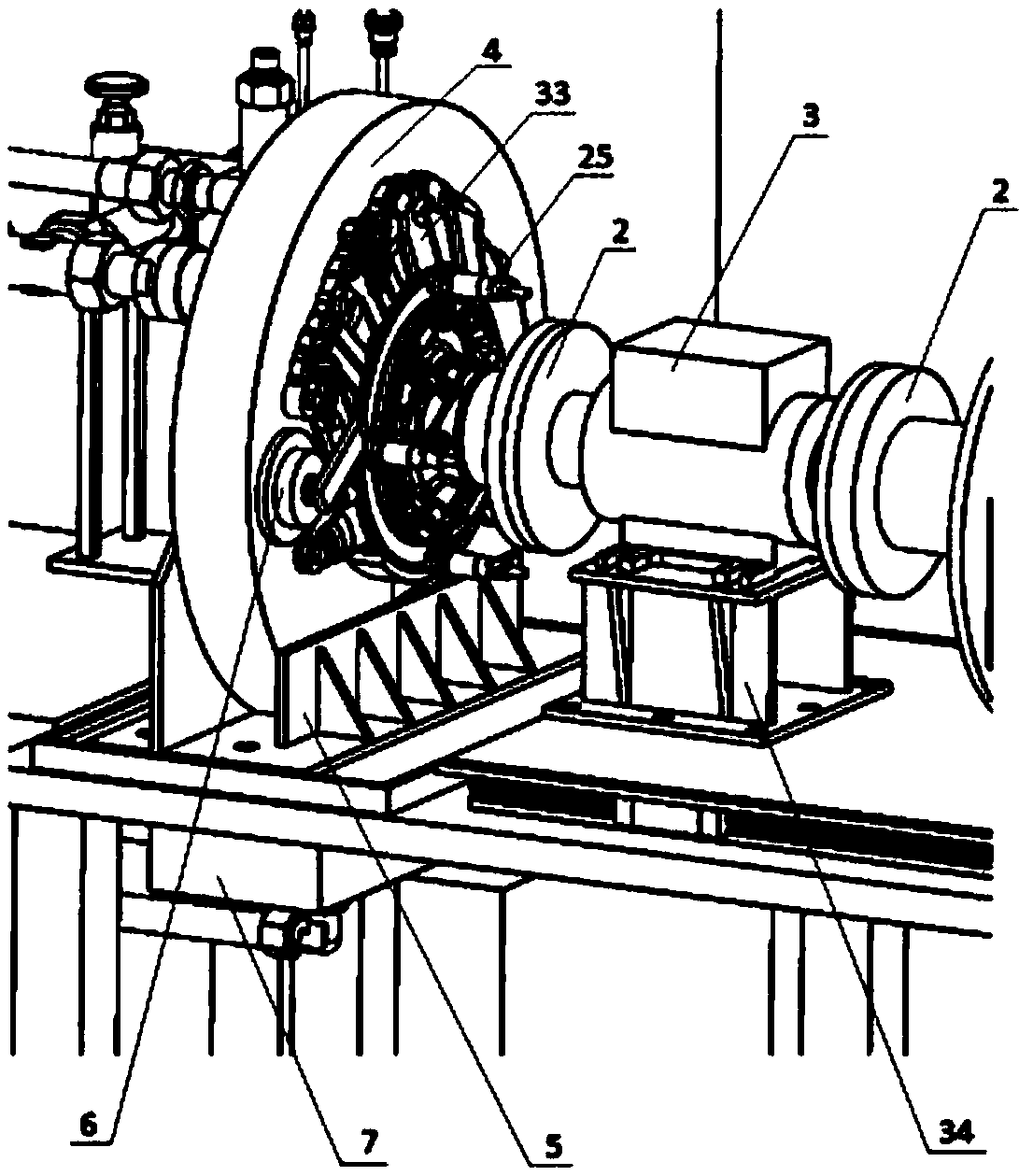

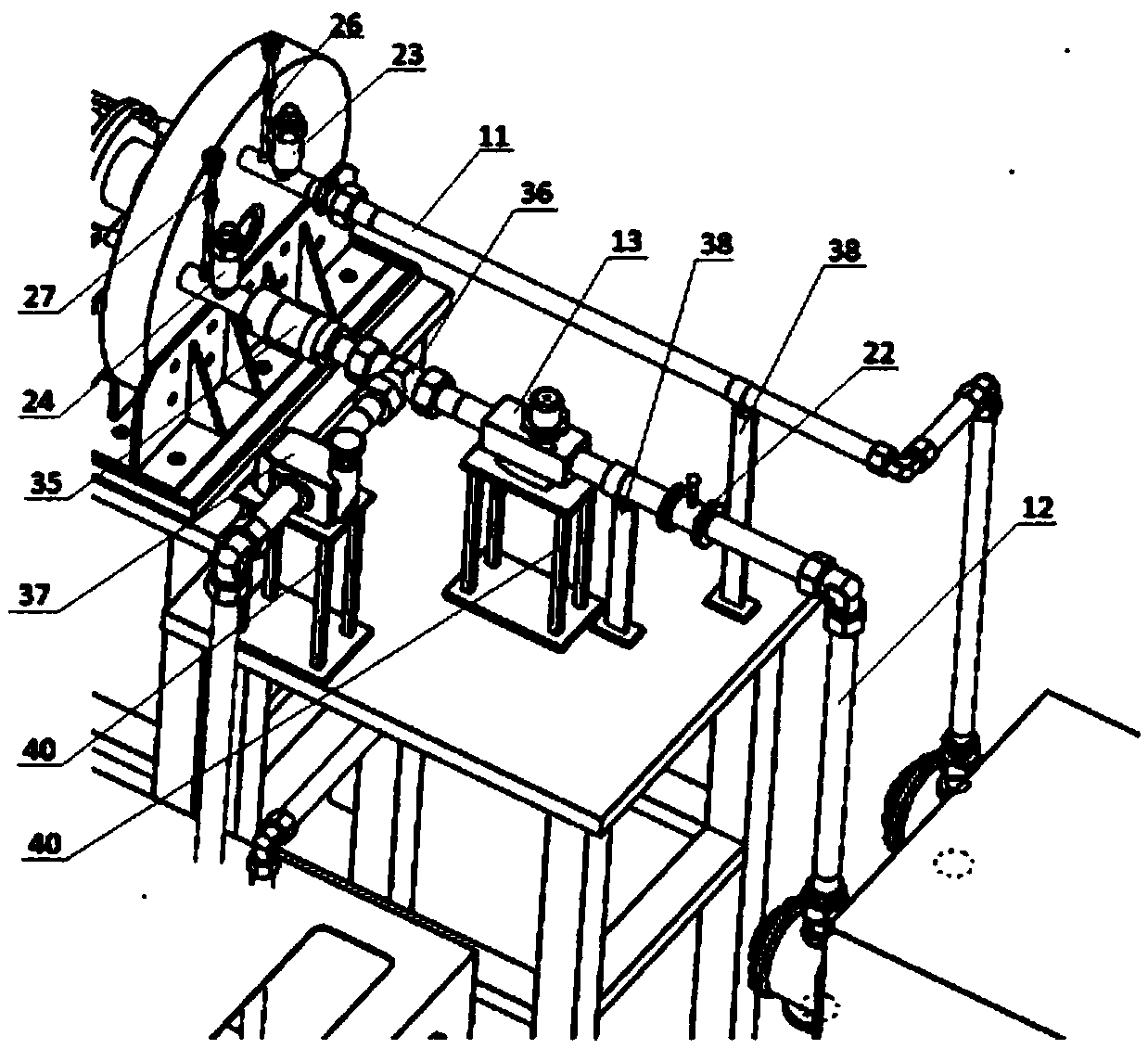

[0025] according to Figure 1-5 As shown, the automotive automatic transmission oil pump full performance test bench in the present invention includes a drive motor 1, a shaft coupling 2, a torque speed sensor 3, a valve seat 4, a fixed base 5, a pneumatic clamping device 6, an oil sump 7, Rodless cylinder 8, linear guide rail 9, transmission system fixing plate 10, oil inlet pipe 11, oil outlet pipe 12, oil outlet pressure regulating valve 13, oil inlet filter 14, oil outlet filter 15, heating constant temperature device 16, main oil tank 17 , oil pump 18, auxiliary oil tank 19, tubular cooler 20, liquid level indicator 21, flow sensor 22, inlet pressure sensor 23, outlet pressure sensor 24, noise sensor 25, inlet temperature sensor 26, outlet temperature sensor 27, main Fuel tank temperature sensor 28, safety protection c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com