Bin top steering valve

A technology of steering valve and butterfly valve, applied in lift valve, valve detail, multi-way valve, etc., can solve the problems of increasing production cost and height of on-site installation space, unable to meet production requirements, debris easily falling into materials, etc. Small, reasonable feeding distribution, high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the orientation terms such as left, middle, right, up, and down in the examples of the present invention are only relative concepts or refer to the normal use state of the product, and should not be considered as restrictive .

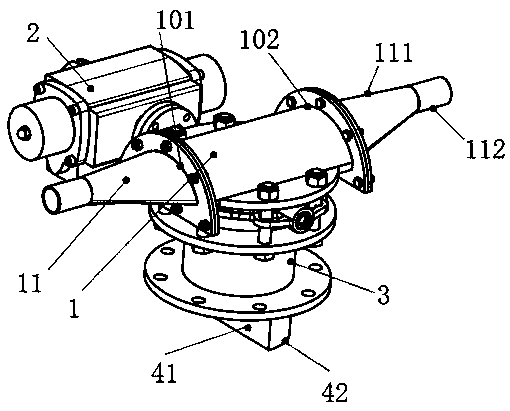

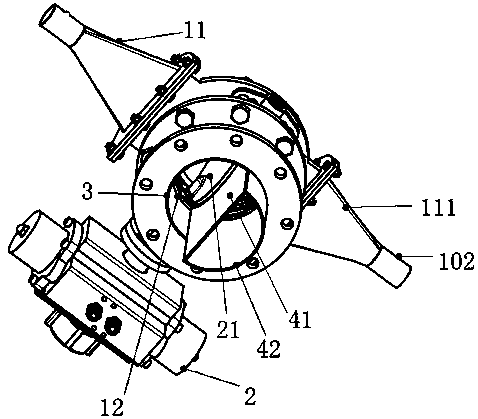

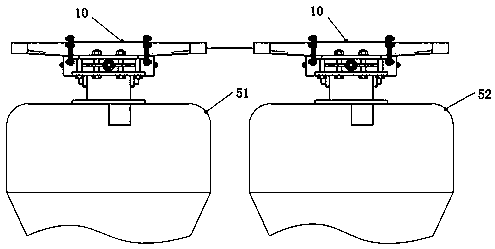

[0020] A silo top steering valve, comprising a semi-cylindrical diversion chamber 1 with openings at both ends. The openings at both ends of the diversion chamber 1 are feed inlets 101 and discharge ports 102 respectively. There is a circular discharge port 12, the radius of the discharge port 12 is the same as that of the diversion chamber 1, a butterfly valve 2 is arranged on the diversion chamber 1, and the circular partition 21 set by the butterfly valve 2 is rotatably installed at the discharge port 12 And matched with the discharge port 12 , the rotation axis of the circular partition 21 is arranged vertically to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com