Dehumidification drying unit adopting an air inlet precooling and efficient dehumidification combined module and drying device

A pre-cooling and air intake technology, which is applied in the direction of dryers, dryers for static materials, drying, etc., can solve the problems of low proportion of heat and humidity load, lower dew point temperature, lower relative humidity, etc., and achieve an increase in area air volume ratio , The effect of reducing the air volume and reducing the number of operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

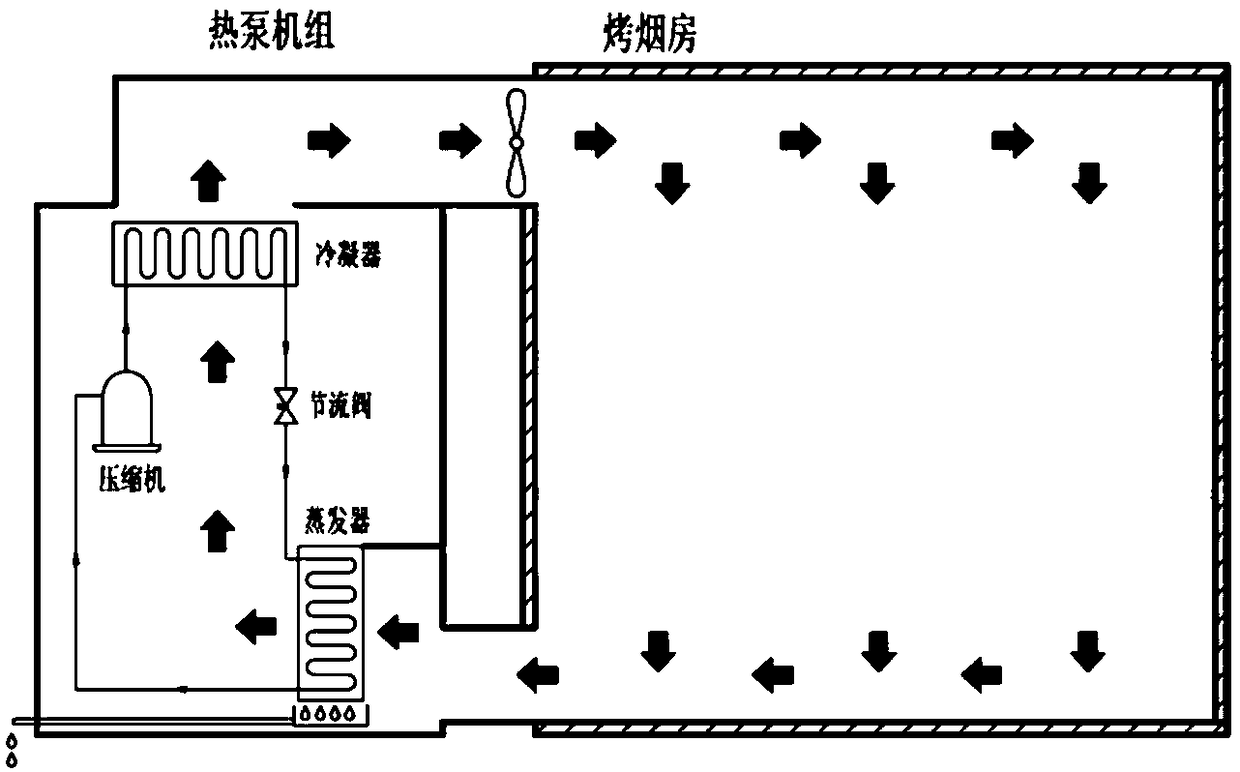

[0044] refer to figure 2 , the present invention provides a dehumidification and drying unit adopting an air inlet precooling and high-efficiency dehumidification combination module, which includes at least two sets of heat pump units, and each set of heat pump units includes a compressor connected in sequence to form a closed system for refrigerant circulation, Condenser, throttling device, internal dehumidification evaporator; also includes a cross-flow heat exchanger BH, cross-flow heat exchanger BH has a cross-flow arrangement of the first heat exchange channel (ie hot fluid channel) and the second heat exchange channel (i.e. the cold fluid channel), the air outlet of the first heat exchange channel and the air inlet of the second heat exchange channel are connected through a circulation channel; the internal dehumidification evaporators of multiple sets of heat pump units are arranged in sequence in the circulation channel and located The air outlet of the first heat exc...

Embodiment 2

[0078] This embodiment is an adjustment made on the basis of Embodiment 2.

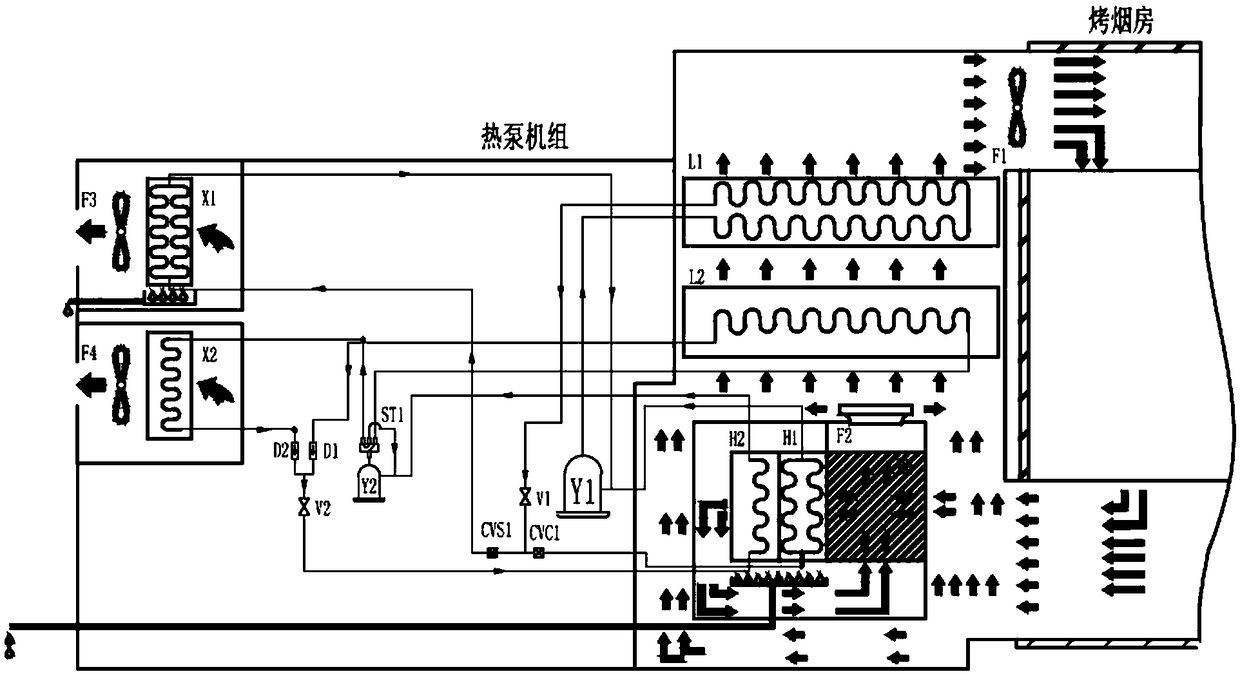

[0079] specific reference image 3 , the dehumidification and drying unit includes two sets of heat pump units, a first heat pump unit and a second heat pump unit.

[0080] In this embodiment, the first heat pump unit includes a first compressor Y1, a first condenser L1, a first throttling device V1, and a first internal dehumidification evaporator H1 connected in sequence; the first heat pump unit also includes a second An outdoor heat exchanger X1, the first outdoor heat exchanger X1 is placed outdoors, and a fan F3 is provided on one side of the first outdoor heat exchanger X1 to promote the flow of outdoor air through the first outdoor heat exchanger X1.

[0081] One end of the first outdoor heat exchanger X1 is connected to the second pipeline between the first internal dehumidification evaporator H1 and the first compressor Y1 through the first pipeline, and the other end is connected to the fi...

Embodiment 3

[0128] This embodiment is an adjustment made on the basis of Embodiment 2.

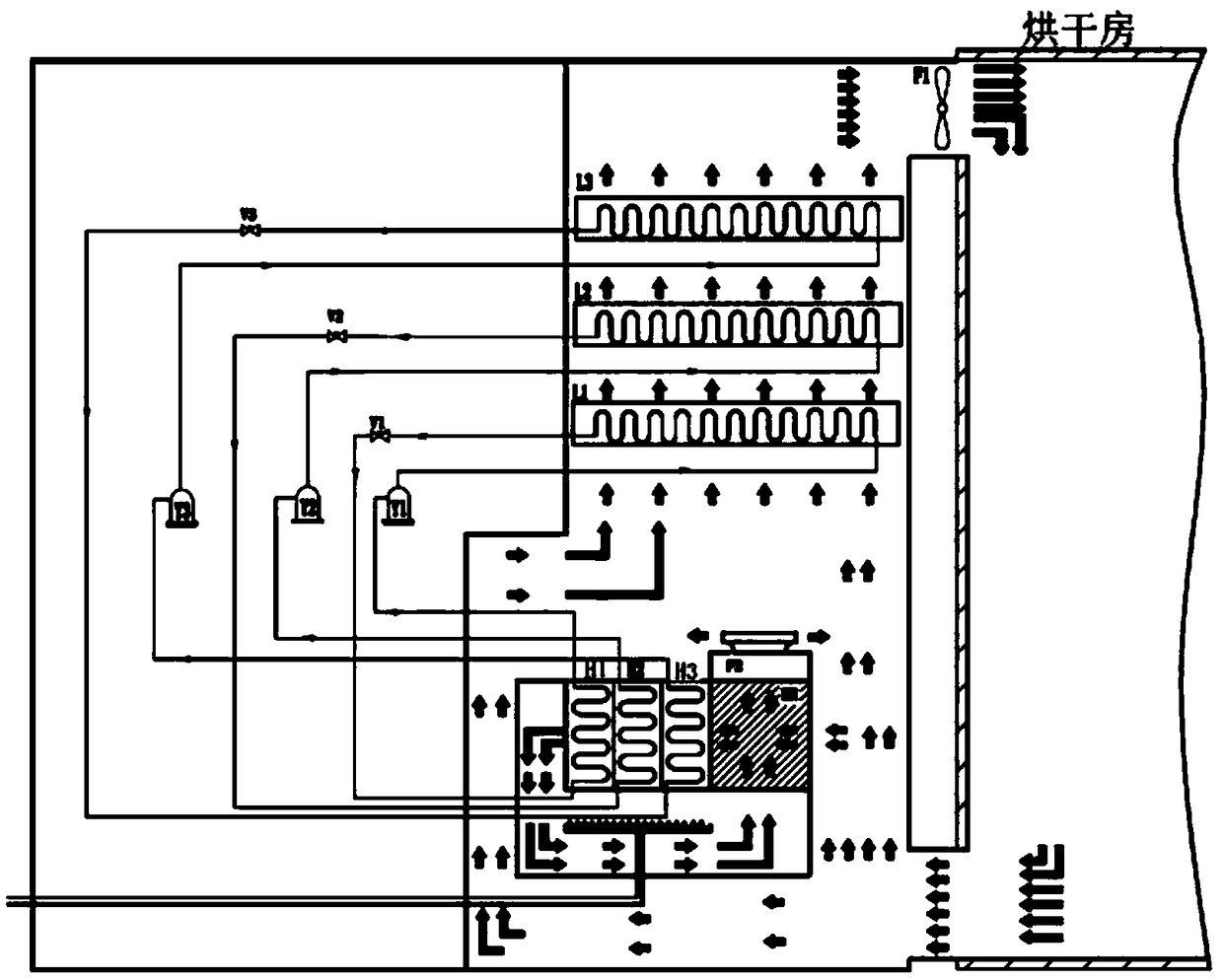

[0129] specific reference Figure 4 , the dehumidification and drying unit includes two first heat pump units and one second heat pump unit. The specific structural forms of the first heat pump unit and the second heat pump unit refer to the description in Embodiment 2, and will not be repeated here.

[0130] The dehumidification and drying unit provided in this embodiment adopts the air intake precooling and high-efficiency dehumidification combination module, which serves for the drying of agricultural products such as tobacco leaves. It adopts 3 sets of "one-to-two" refrigeration systems. In an intake air precooling module:

[0131] ① Two sets of one-to-two refrigeration systems for dehumidification and heating in the drying room

[0132] Each system has one condenser and two evaporators. The condensers are installed in the main air duct, and the two sets of evaporators operate at different times...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com