Grain drying machine

A grain dryer and drying barrel technology, applied in the direction of dryer, drying, dryer combination, etc., can solve the problems of equipment wear, direct discharge of hot air not being effectively used, etc., so as to improve quality and reduce heat dissipation. , the effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

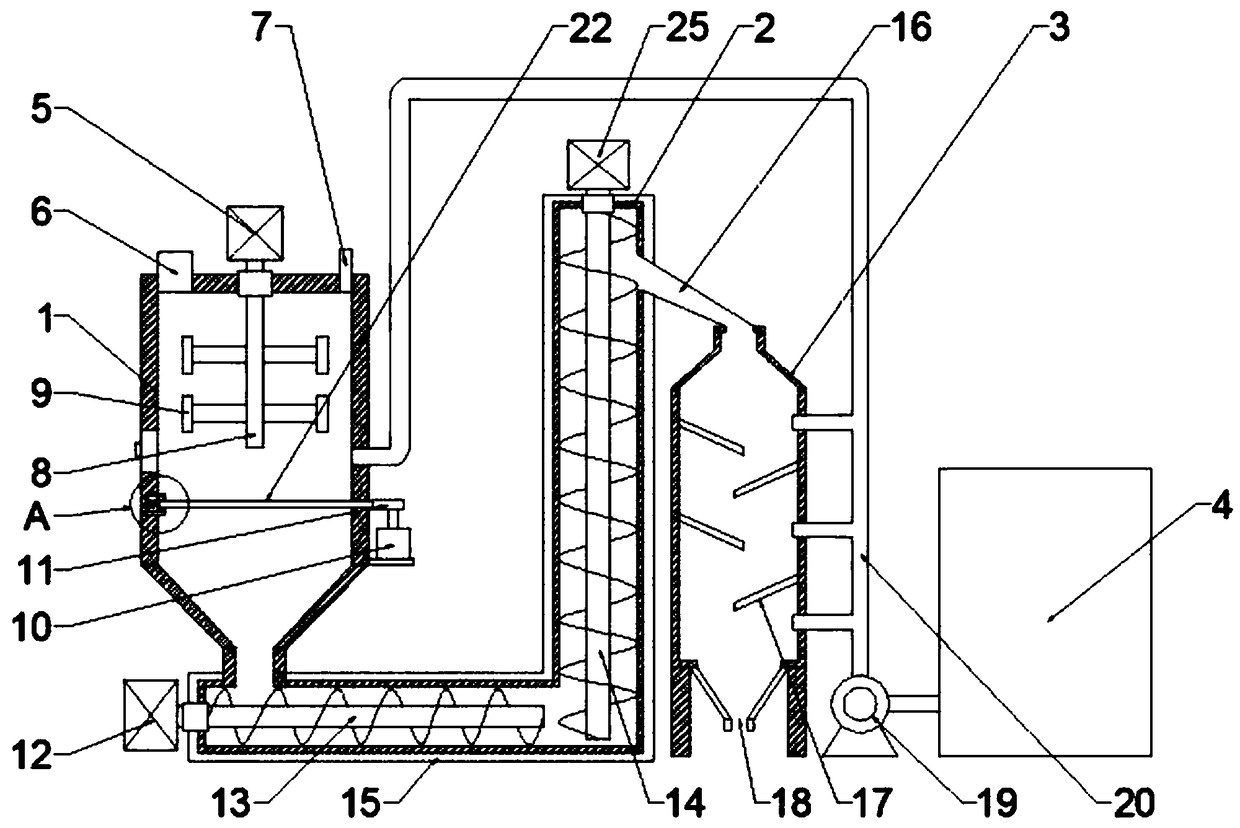

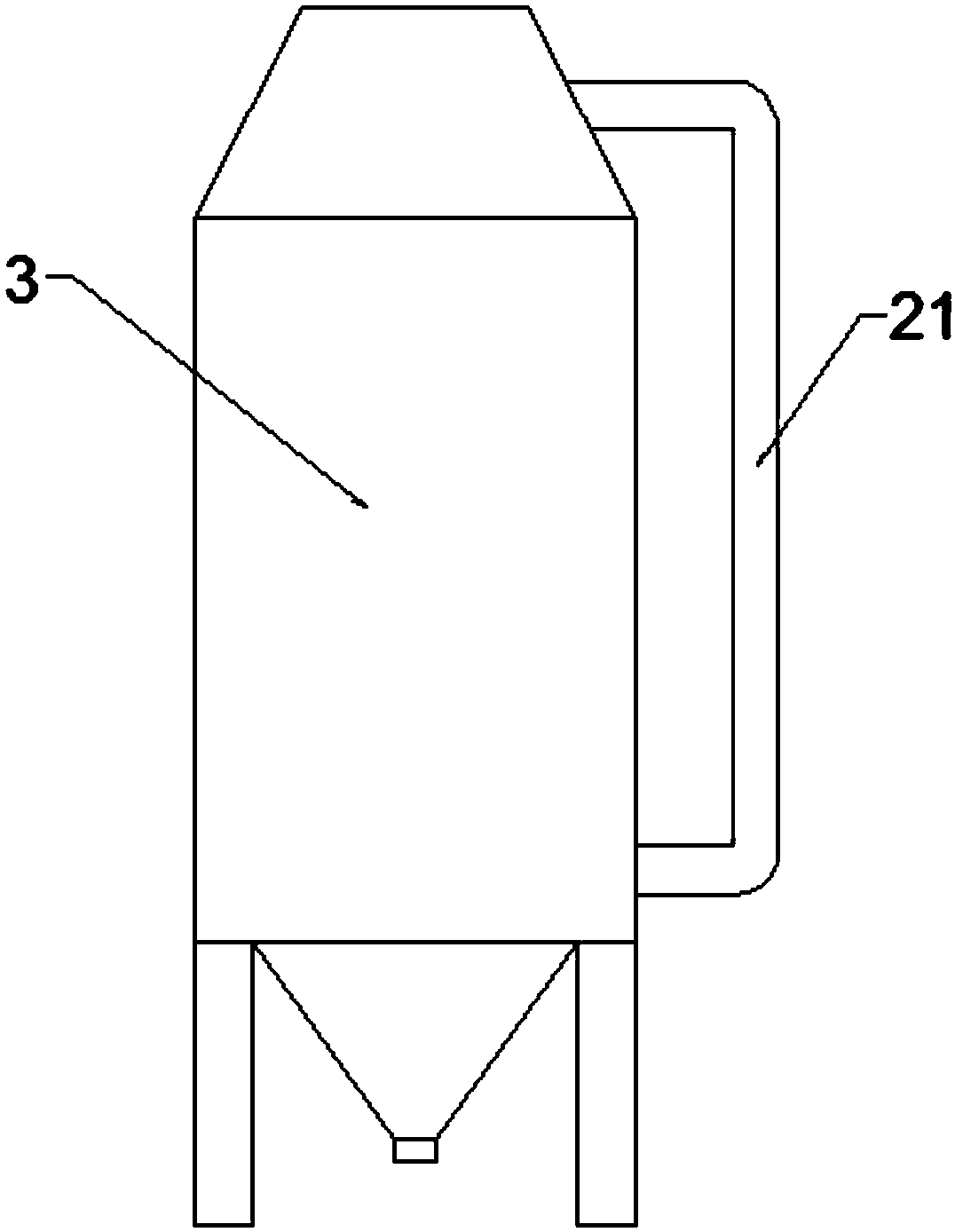

[0022] Such as Figure 1-Figure 3 As shown, a grain dryer proposed by the present invention includes a mixing barrel 1, a conveying device 2 and a drying barrel 3. The mixing barrel 1 is connected to the conveying device 2, the conveying device 2 is connected to the drying barrel 3, and the drying barrel 3 passes through The air pipe 20 is connected to the fan 19, the fan 19 is connected to the hot blast stove 4 through the pipe 20, and the fan 19 is connected to the mixing tank 1 through the air pipe 20;

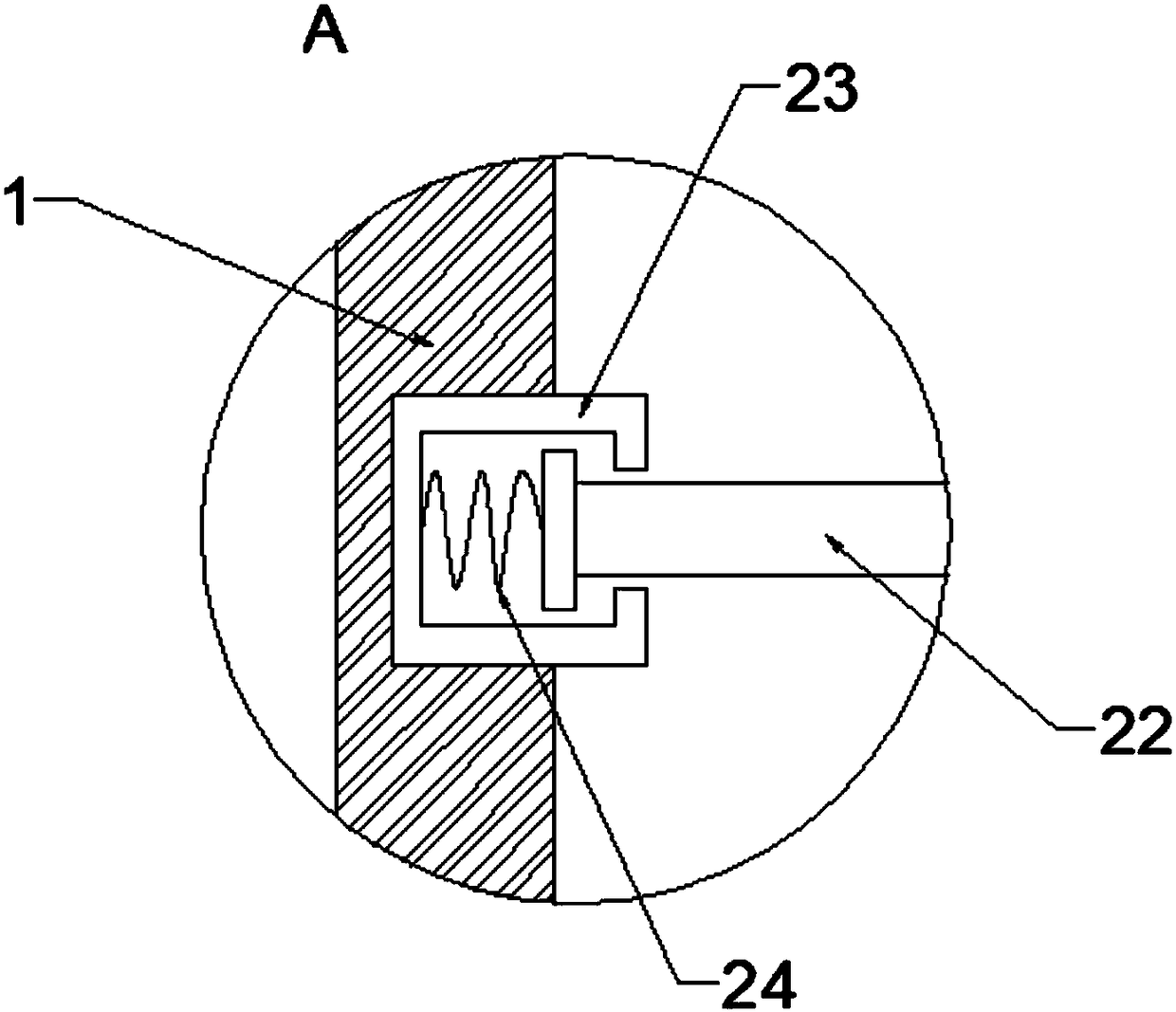

[0023] The middle of the upper end of the mixing barrel 1 is provided with a first motor 5, the first motor 5 is connected to the mixing shaft 8, the mixing shaft 8 is provided with a stirring paddle 9, the first motor 5 is provided with a feed inlet 6 on the left side, and the first motor 5 is provided on the right There is an air outlet 7, and a sieve 22 is provided under the stirring shaft 8;

[0024] A second motor 12 is provided inside the conveying device 2, and the secon...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap