Method for checking correlation degree of carbon emission data of gas unit based on product difference analysis

A technology of data association and inspection method, applied in measurement devices, instruments, etc., can solve the problems of inability to meet the requirements of accurate verification and timely reporting of carbon emissions, and achieve the effect of improving real validity, simple calculation logic, and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

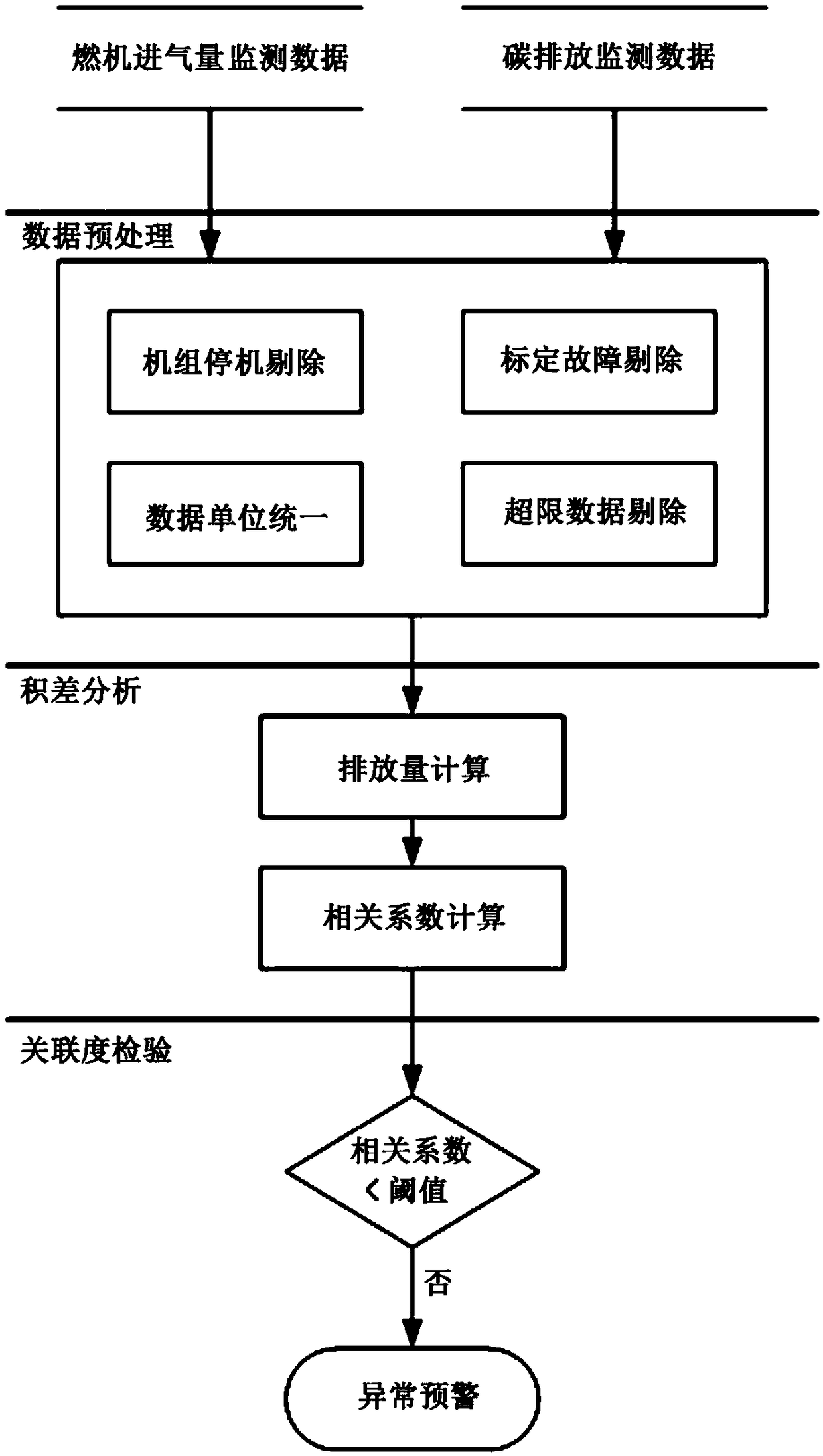

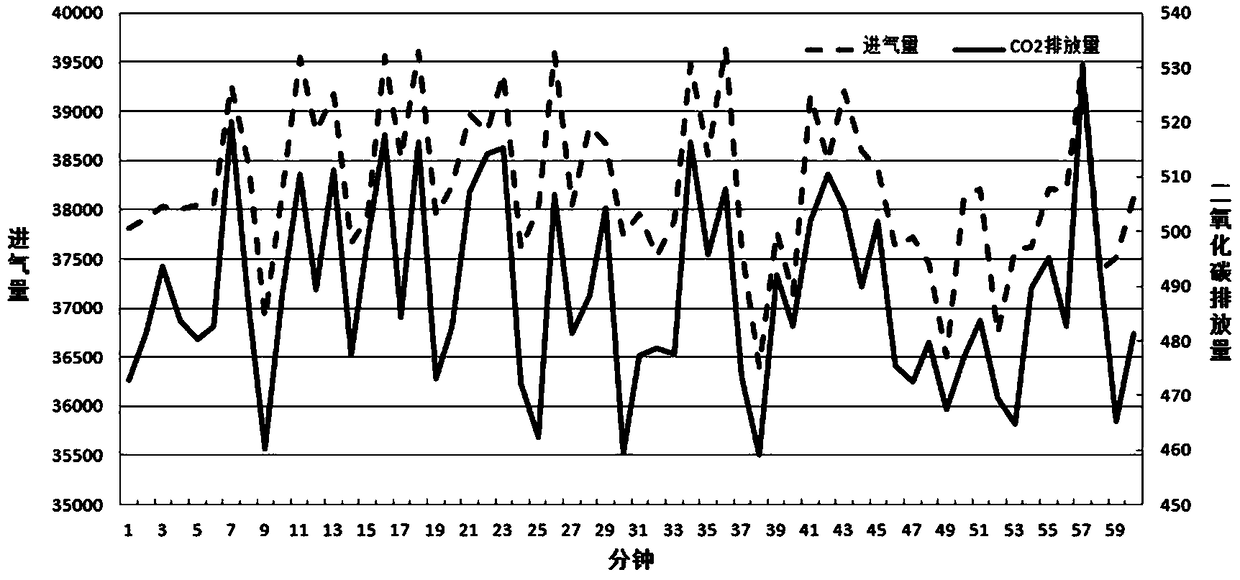

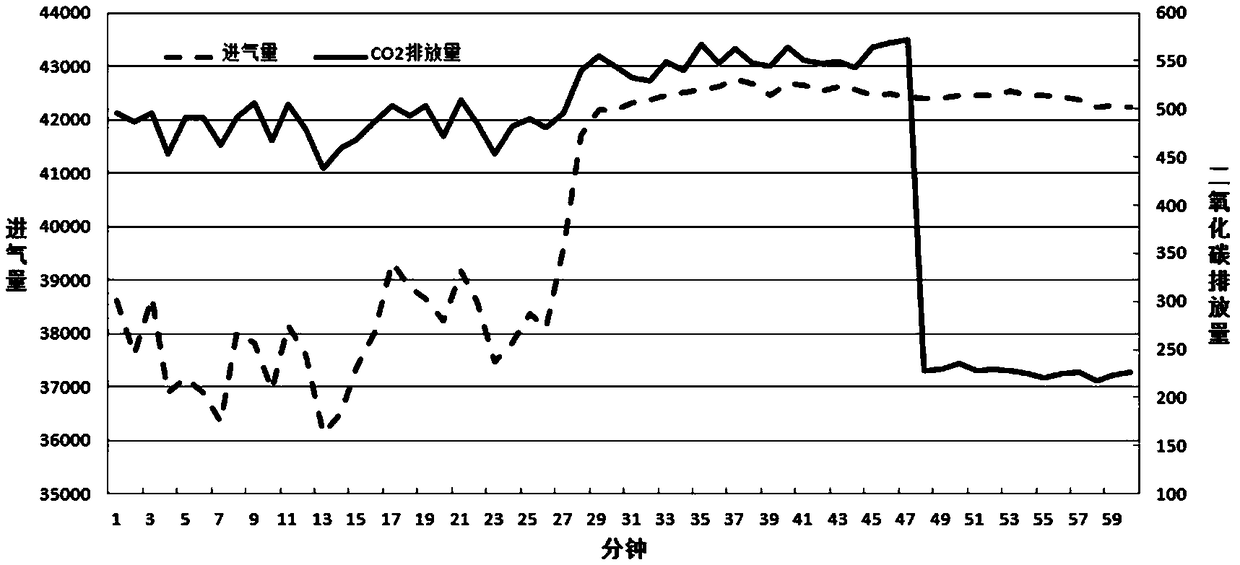

[0042] The following takes a 9F gas-fired unit (test unit) as an example to further describe the present invention in detail, and select the monitoring data of the unit's intake air volume and carbon emission monitoring parameters at 1-minute intervals throughout the day on June 1, 2018 for illustration. The rated load of the gas turbine and steam turbine of the test unit are 475MW and 200MW respectively, and the cross-sectional area of the chimney outlet is 28.26m 2 . see figure 1 , a gas-fired unit carbon emission data correlation inspection method based on cumulative difference analysis of the present invention, comprising the following steps:

[0043] Step 1: Data preprocessing:

[0044] According to the data preprocessing rules, check whether there are shutdowns, calibration failures, and out-of-limit data in the monitoring data, and remove the above-mentioned abnormal data from the monitoring data set. Since the on-site measurement unit of the exhaust gas pressure o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com