T-joint shear testing device

A shear test and indenter technology, which is used in measuring devices, using a stable shear force to test material strength, instruments, etc., can solve problems such as the inability to simulate pure shear loads and impure shear failures. , to achieve the effect of improving sample efficiency, simplifying sample installation, and simplifying test steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and effect of the present invention clearer and clearer, the following examples are given to further describe the present invention in detail. It should be pointed out that the specific implementations described here are only used to explain the present invention, not to limit the present invention.

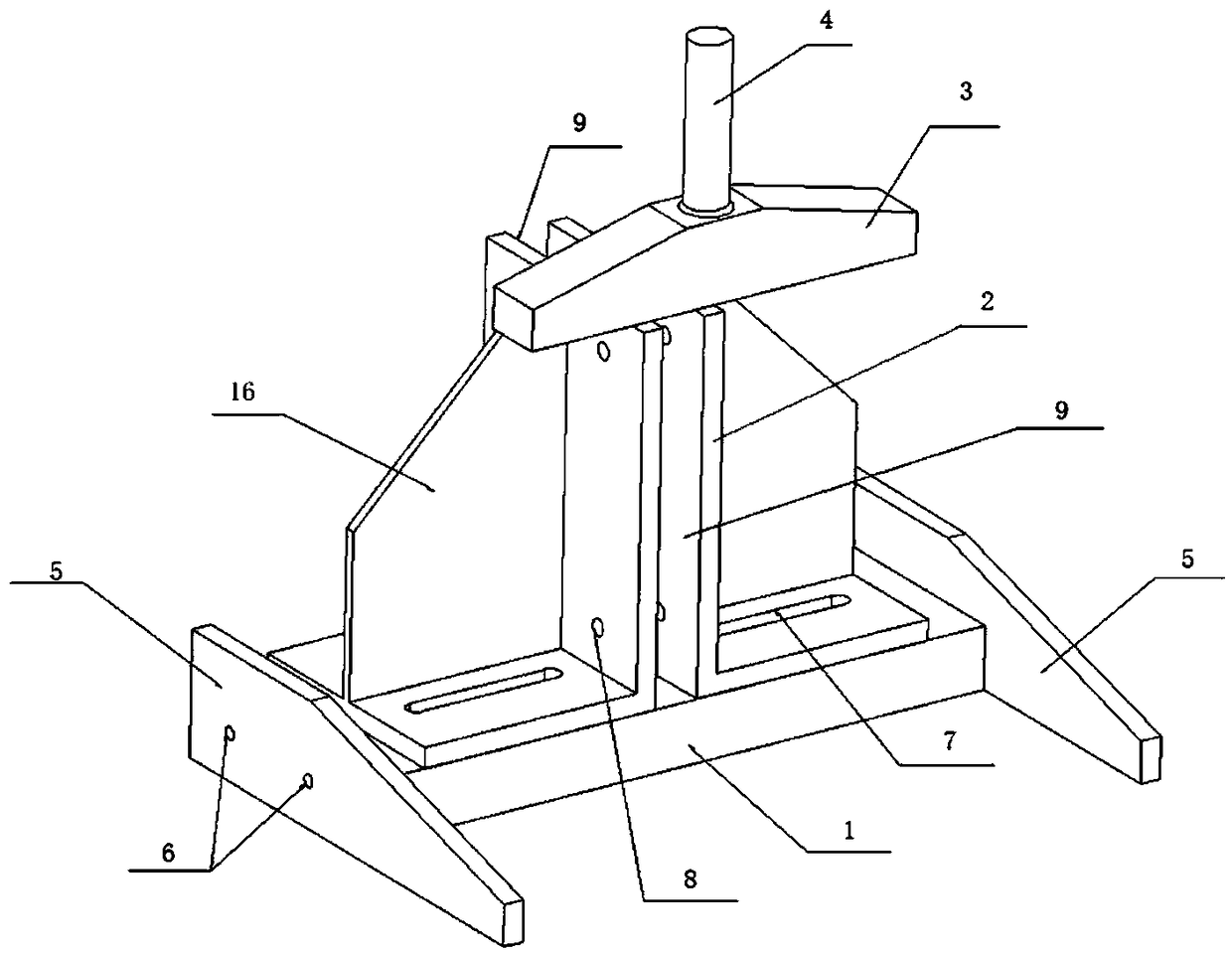

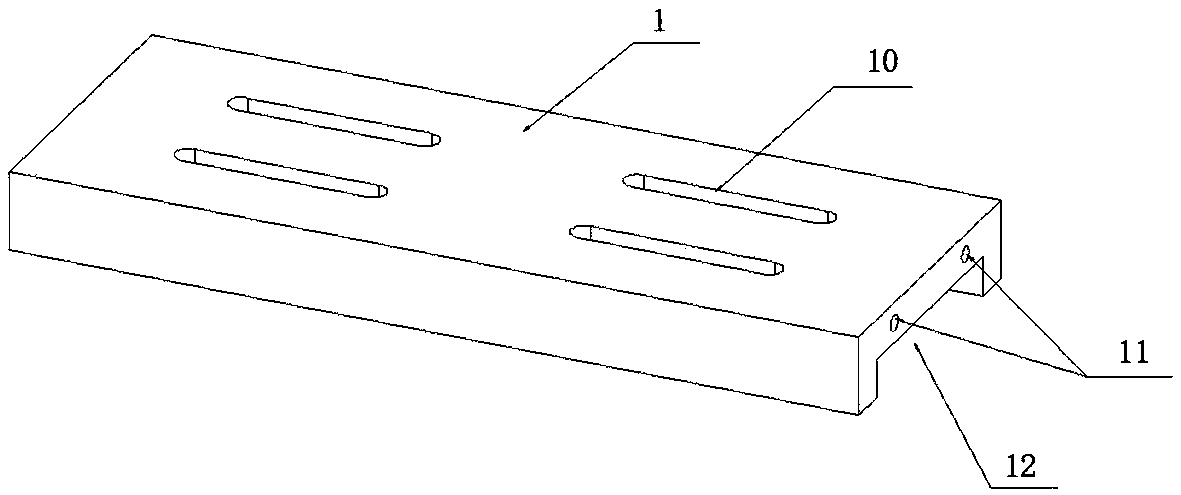

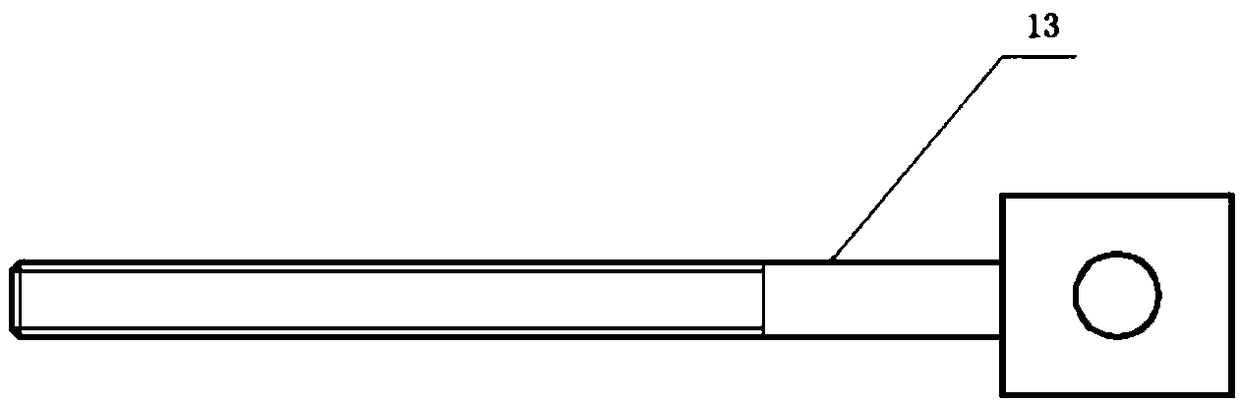

[0026] Such as Figure 1~2 As shown, the main device of the present invention includes a base 1, and support plates 5 are placed on both sides of the base to prevent the test device from tilting due to uneven force. The support plate 5 is a flat plate structure based on an equal rigidity design. Support plate bolt holes 6 are provided on the support plate 5, and base bolt holes 11 are provided on both sides of the base 1. The support plate bolt holes 6 correspond to the opening positions of the base bolt holes 11. image 3 The shown locking bolts 13 respectively pass through the bolt holes 6 of the support plate and the bolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com