Image acquisition system for detecting flaws of textiles

An image acquisition system and textile technology, applied in measuring devices, optical testing of flaws/defects, material analysis through optical means, etc., can solve problems such as digital image data sources cannot be accurately sampled, and achieve good application prospects and work stability High, the effect of improving the signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings.

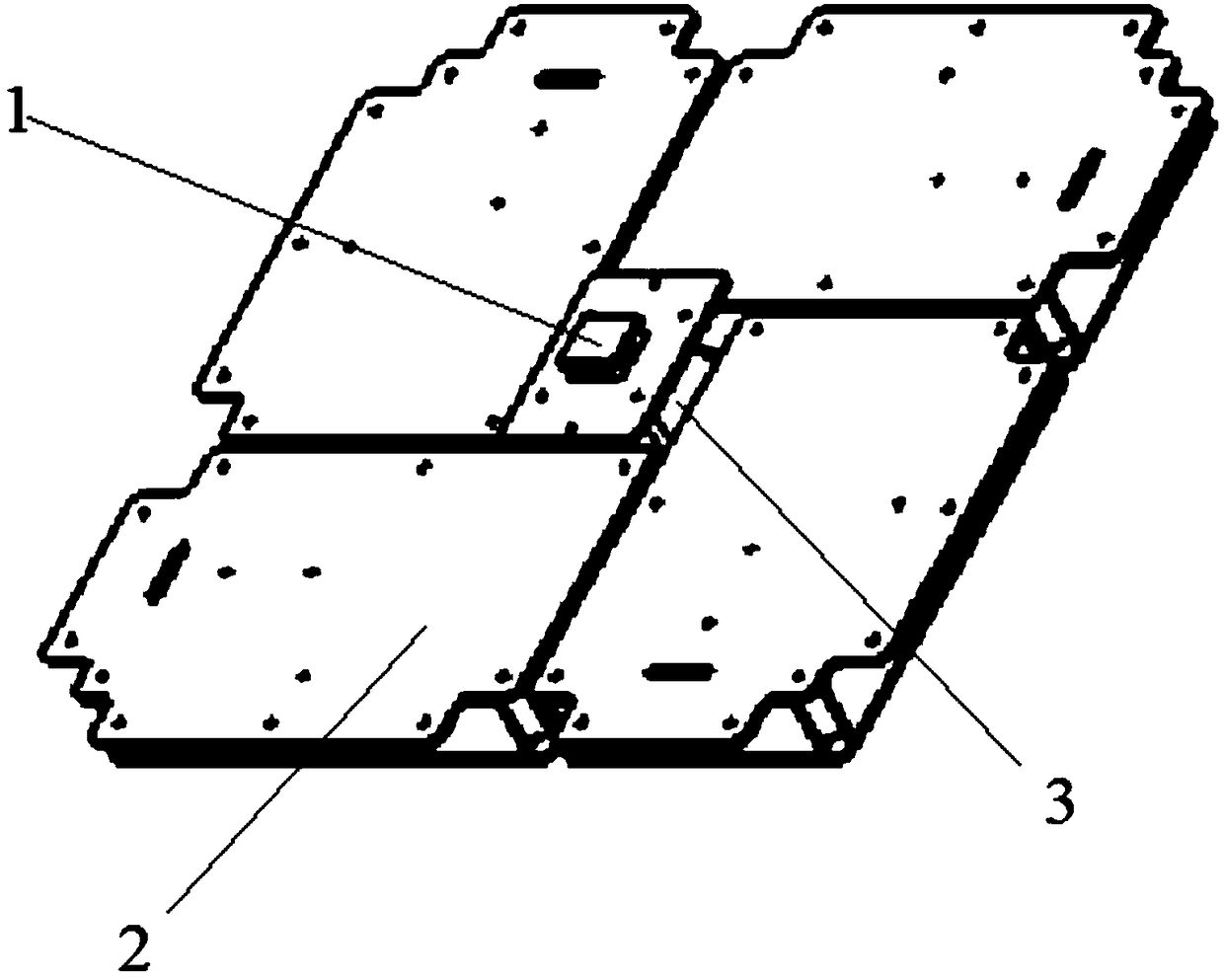

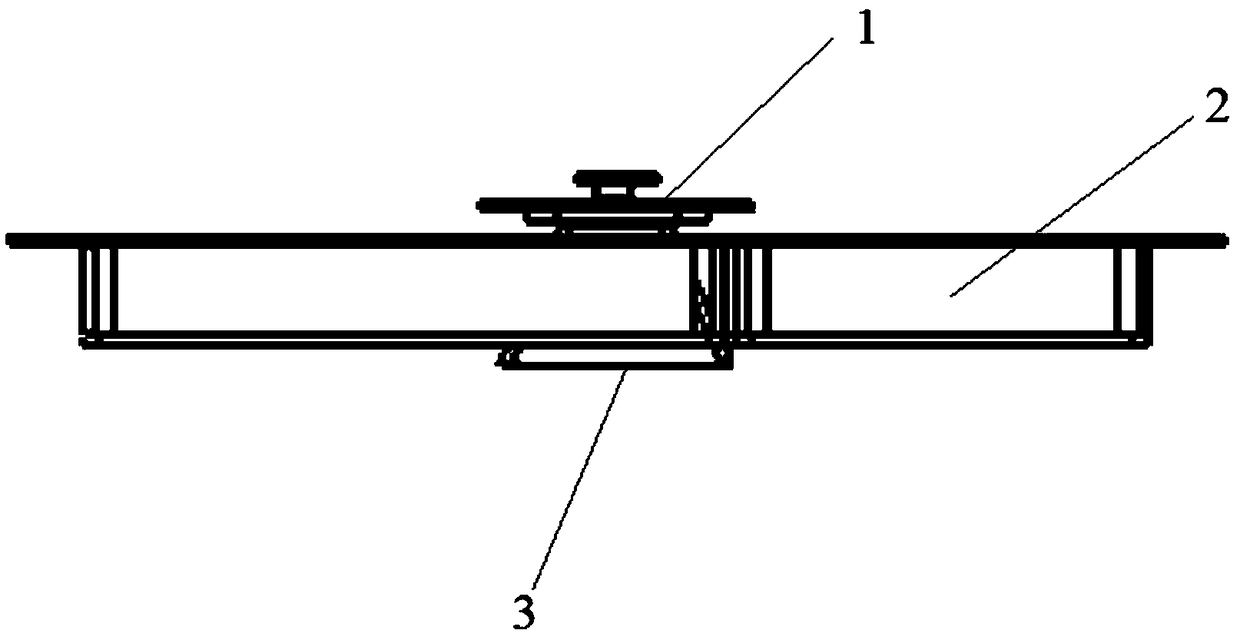

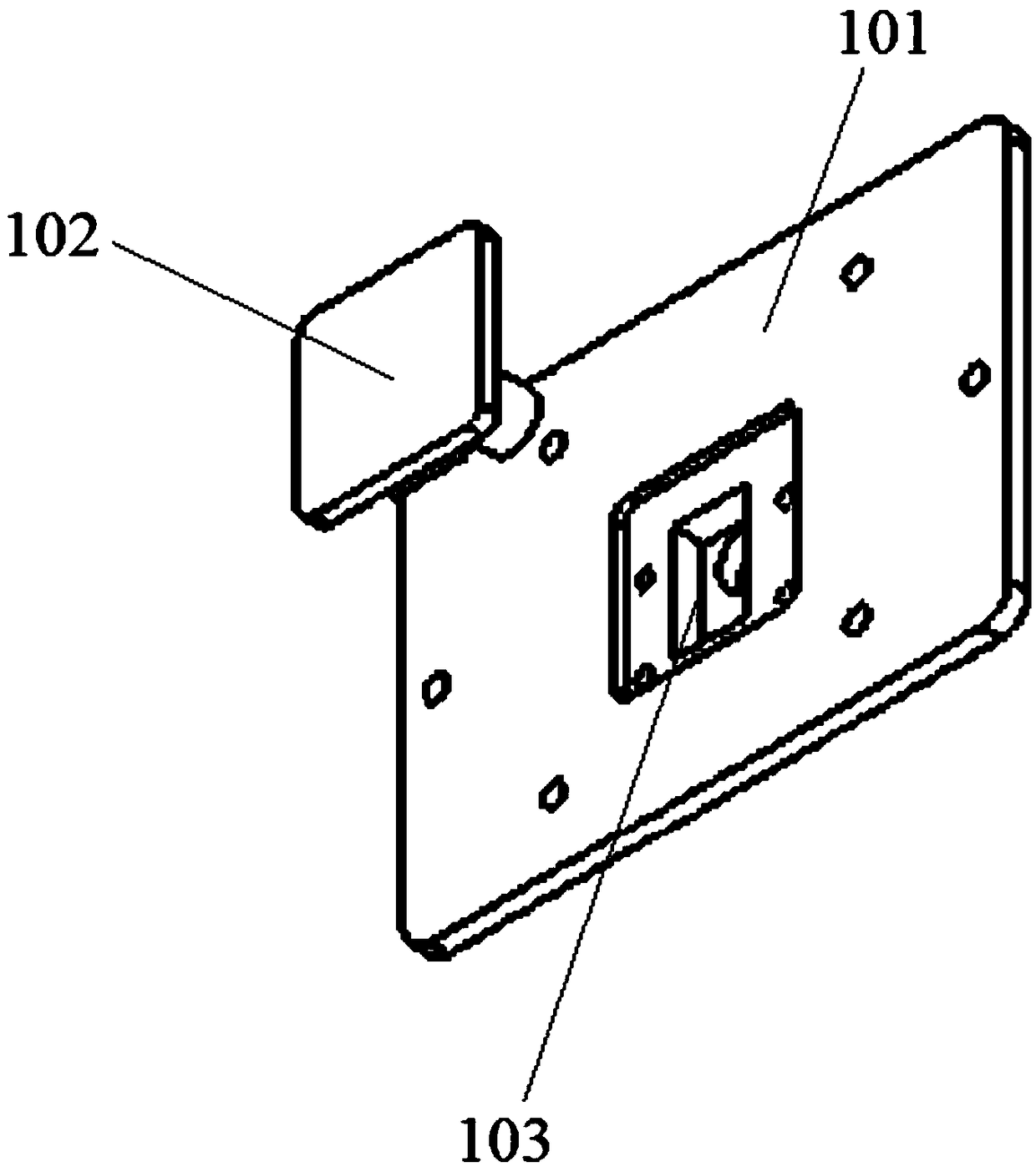

[0038] Such as figure 1 and figure 2 As shown, the image acquisition system for textile defect detection of the present invention includes a micro-camera assembly 1 located directly above the direction of transmission of the textile to be detected, and the circumference of the micro-camera assembly 1 is provided with supplementary light sources distributed at equal intervals Assembly 2, the miniature camera assembly 1 is clamped in the reserved area in the middle of the supplementary light source assembly 2, and the miniature camera assembly 1 is fixed with a hood assembly 3 in the shooting direction,

[0039] The shading cover assembly 3 extends downward from the reserved area on the plane where the supplementary light source assembly 2 is located, and the length of the shading cover assembly 3 extending from the plane where the supplementary light source assembly 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com