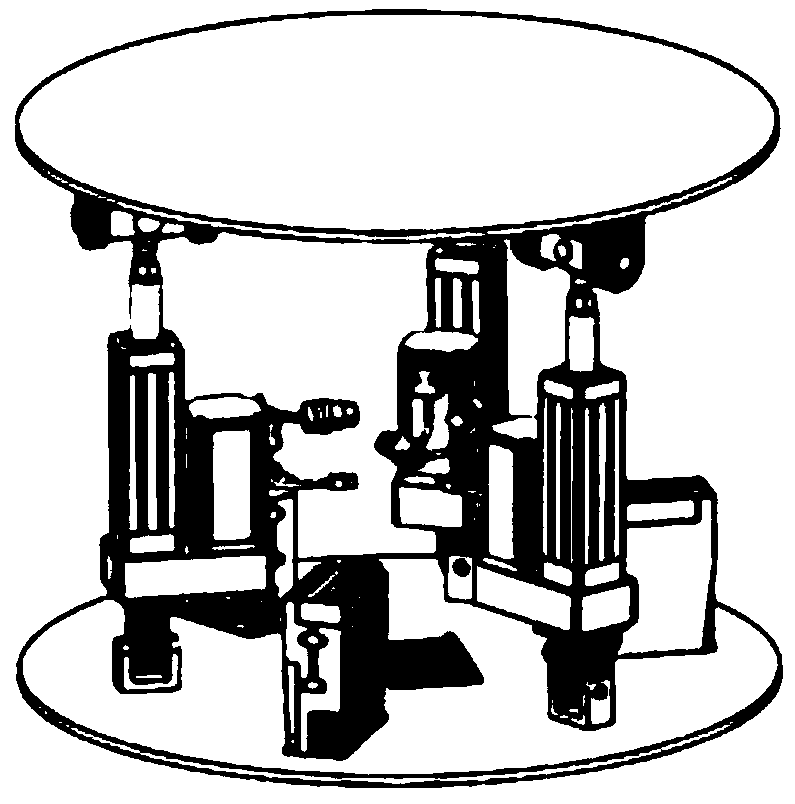

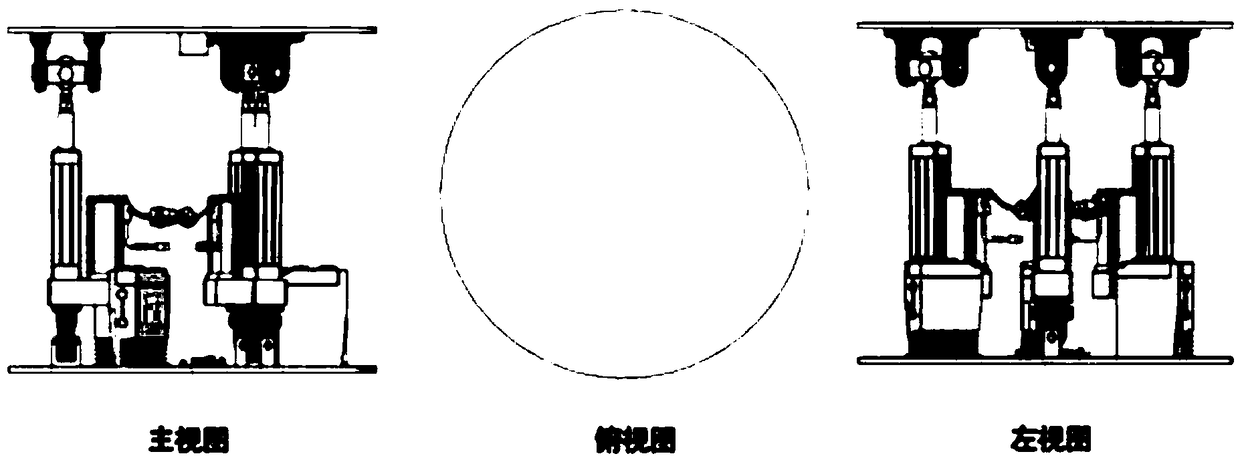

Self-balance platform for woodland machinery

A self-balancing, mechanical technology, applied in non-electric variable control, instrument, attitude control and other directions, can solve the problem of data accuracy cannot be guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific examples.

[0018] After the three-degree-of-freedom self-balancing platform is turned on, record the position of the electric cylinder, perform position calibration, and set it as the initial safe position.

[0019] After the initial position calibration, the adjustment device will adjust the level of the upper platform according to the environment.

[0020] Adjustment is divided into automatic adjustment and manual adjustment.

[0021] During automatic adjustment, the gyroscope installed on the upper platform of the adjustment device will transmit the position angle signal to the control system.

[0022] The control system enters the computer calculation through the computer communication interface of the lower computer for the feedback signal (a displacement Z, pitch angle α, and roll angle β) from the gyroscope to the attitude of the upper platform, and converts it into 3 electric cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com