Method for measuring tire static load mark

A static load and measurement method technology, applied in image data processing, instruments, calculations, etc., can solve problems such as low measurement accuracy, low detection efficiency, and poor applicability, and achieve high precision, improved accuracy, and fast speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

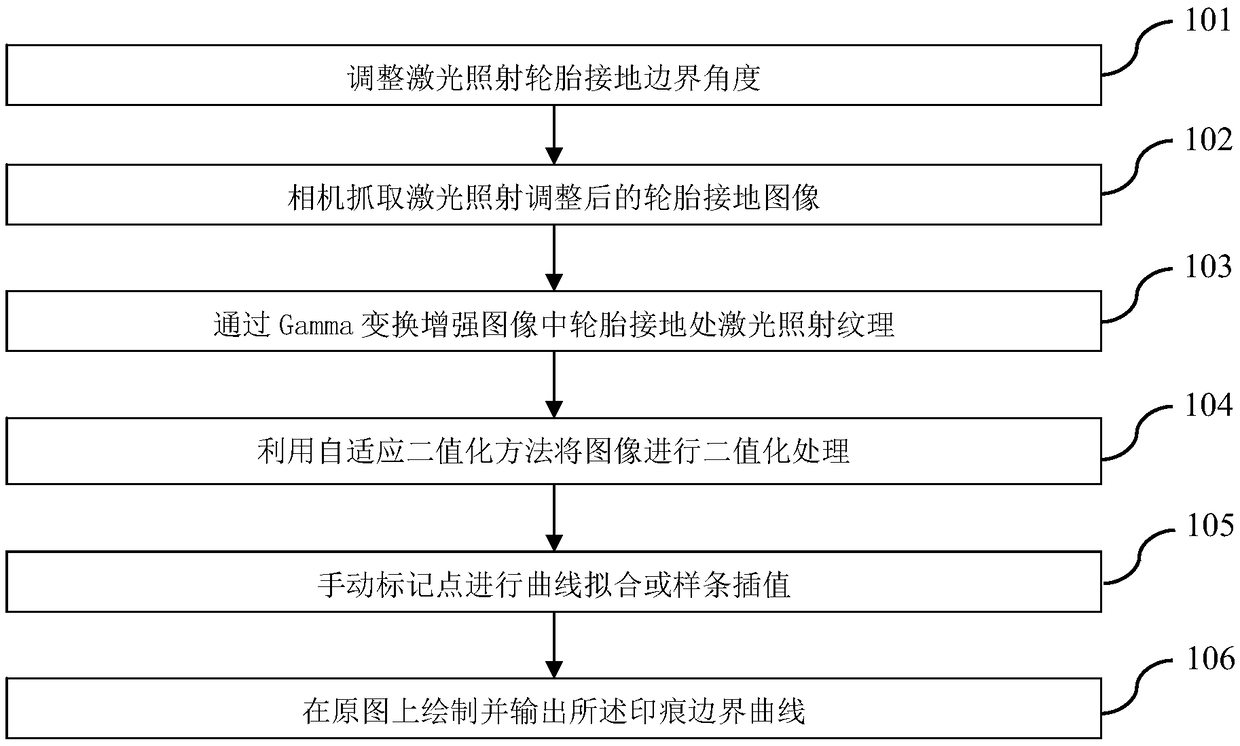

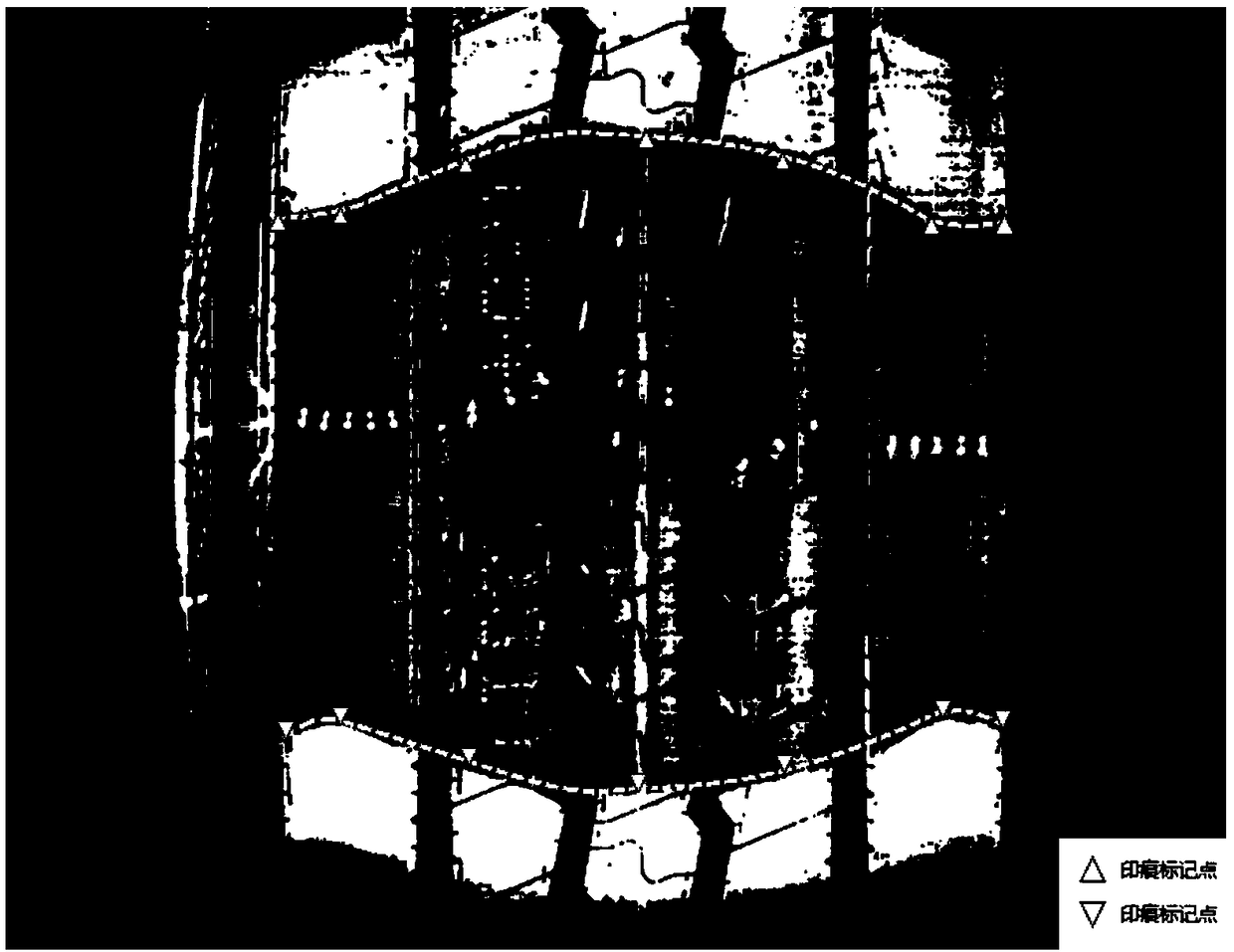

[0018] The present invention will be described below in conjunction with the accompanying drawings.

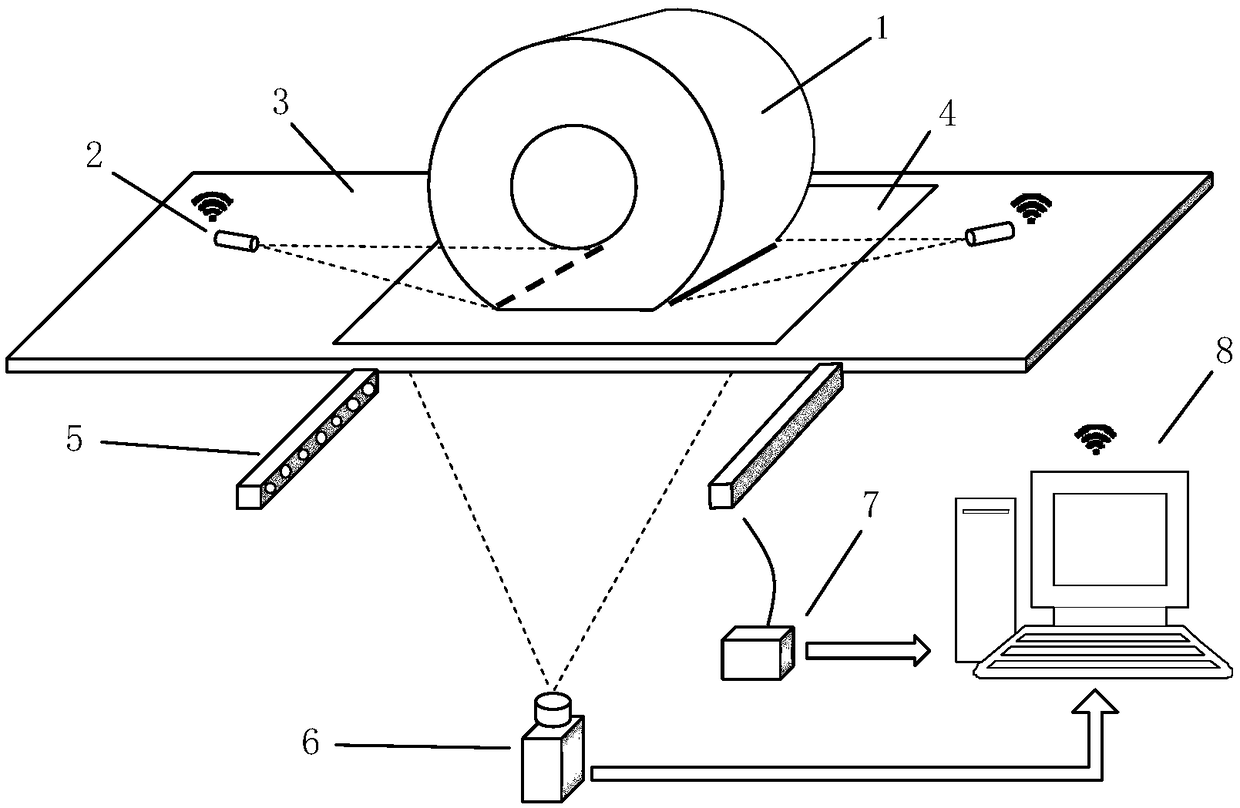

[0019] As shown in 3, the tire static print test system includes a test bench and a workstation 8. The test bench includes a common bench 3 and a glass table 4. When the system is working, the tire 1 is subjected to a load and contacts the glass table 4 to form an impression. Two lasers 2 They are installed on the front and rear sides of the tire respectively, and are connected to and controlled by the workstation 8 using WIFI. Two sets of LED lighting sources 5 are fixed under the glass platen, and the LED light sources are connected to and controlled by the controller 7 , and the controller 7 is connected to the workstation 8 at the same time. A camera 6 is arranged directly under the glass platen to collect images of tire contact marks. The tire and the glass platform contact under load to form a contact surface. The camera is fixed directly under the glass platform to en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com