Fully-automatic special-type wire stock twisting and peeling machine

A fully automatic, twisting and stripping machine technology, which is applied in the field of twisting machines, can solve the problems of inconvenient operation and inability to modify, and achieve the effects of easy on-site operation, cleanliness, and correct position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

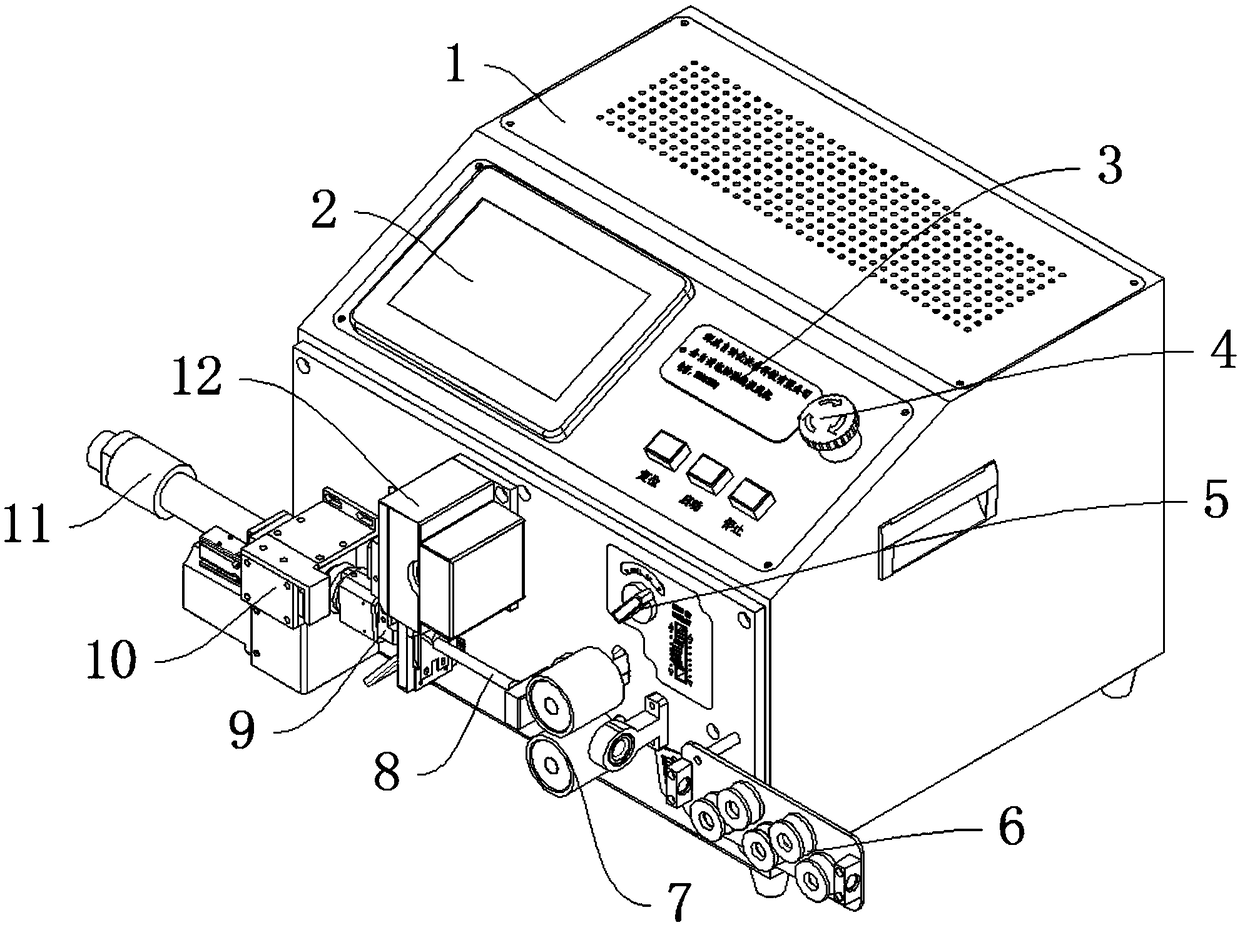

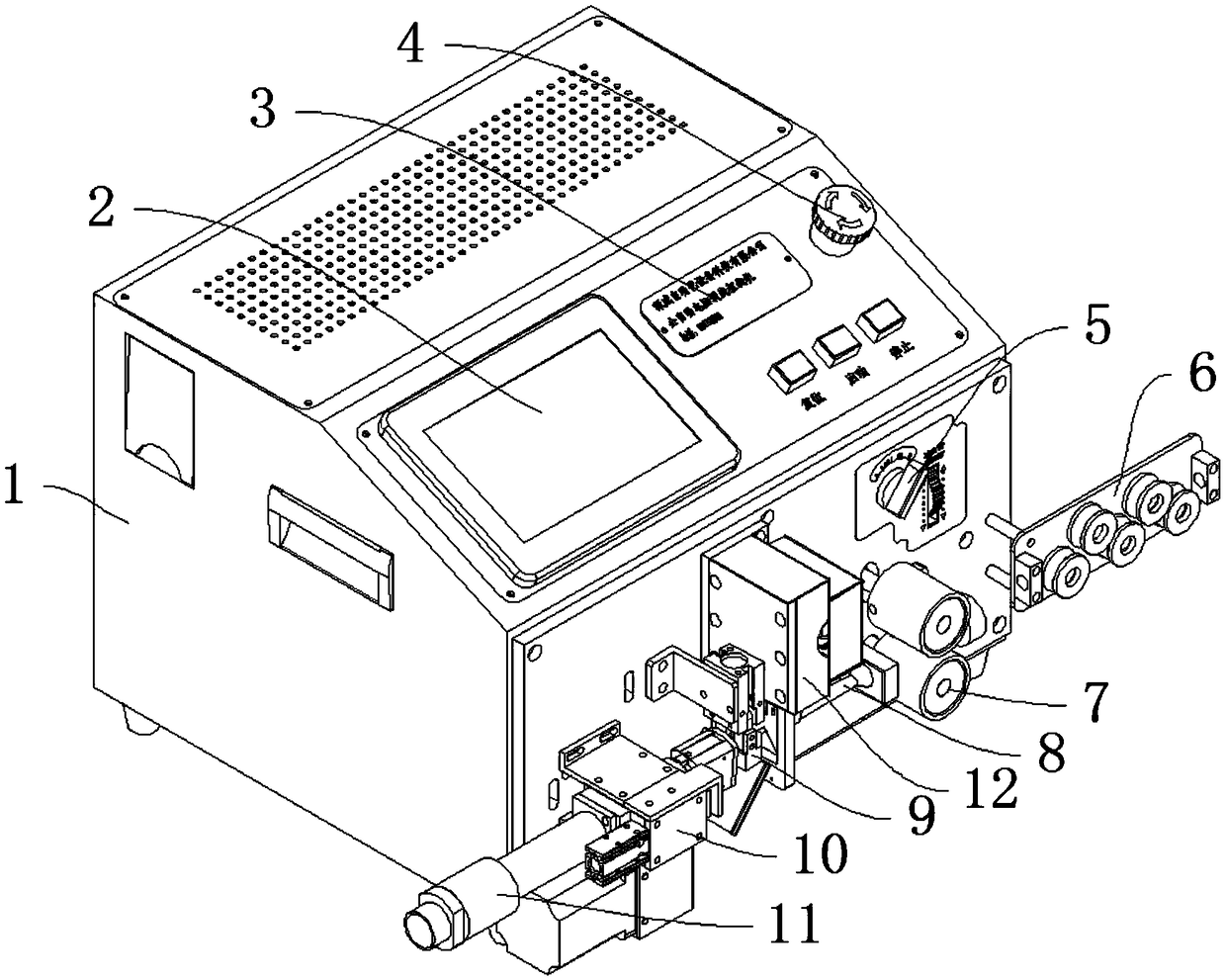

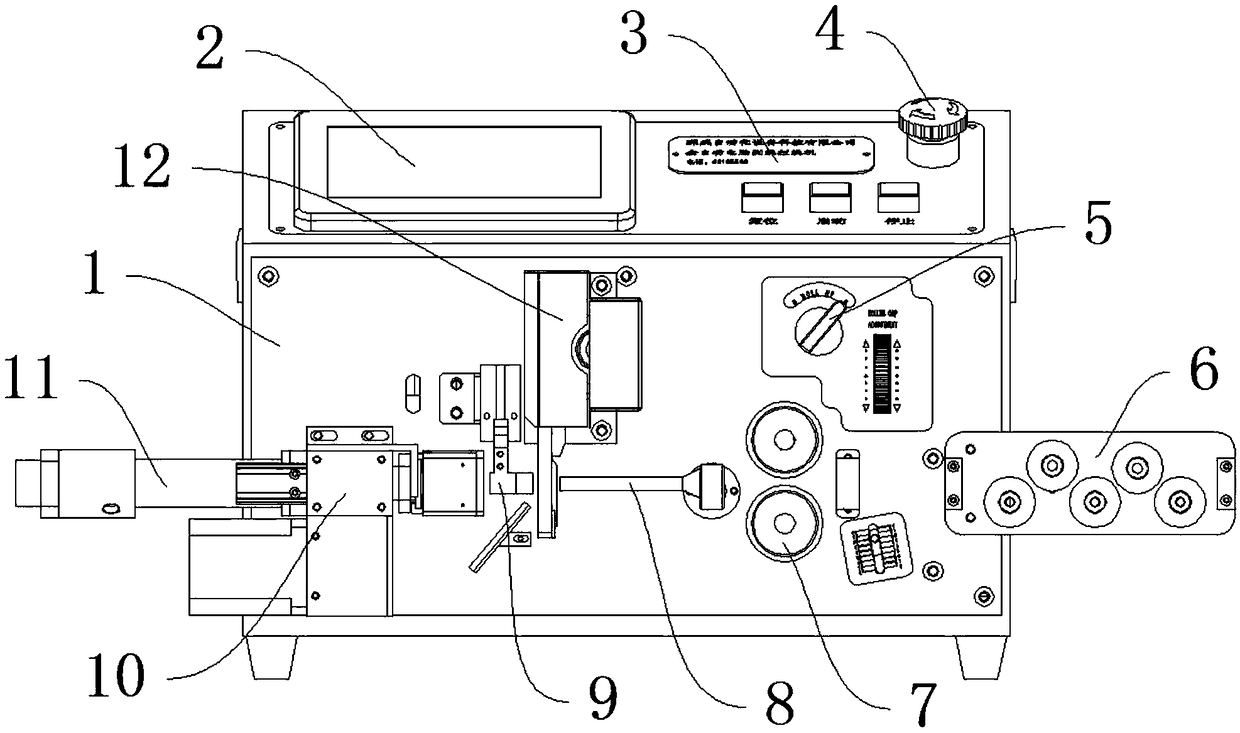

Embodiment 1

[0043] like Figure 1-Figure 6 As shown, the fully automatic special wire twisting and stripping machine includes a casing 1, a tool holder 12, and a wire feeding wheel 7. A PLC touch screen 2 is set on the top of the casing 1, which is convenient for inputting adjustment parameters for control. A nameplate 3 is set on one side of the PLC touch screen 2. Write down the machine data, the nameplate 3 side is provided with an emergency stop button 4, which controls emergency stop, the front of the shell 1 is provided with a whole line mechanism 6, which arranges the wire, and the side of the whole line mechanism 6 is provided with a wire feeding wheel 7, which controls the movement of the wire, A locking switch 5 is arranged above the wire feeding wheel 7 to make the wire feeding wheel 7 press the wire rod. A wire guide tube 8 is arranged on one side of the wire feeding wheel 7 to support the wire rod. A knife holder 12 is arranged on one side of the wire material guide tube 8 to ...

Embodiment 2

[0045] The difference between this embodiment and embodiment 1 is:

[0046] The PLC touch screen 2 and the casing 1 are connected by bolts, which are convenient for disassembly and maintenance of the PLC touch screen 2, and the nameplate 3 is riveted on the casing 1, and the riveting makes the nameplate 3 firm and reliable.

[0047] Working principle: Manually pass the wire through the whole wire mechanism 6, the wire feeding wheel 7, and the wire guide 8 in turn, turn the locking switch 5, the wire feeding wheel 7 clamps the wire, input parameters through the PLC touch screen 2, after starting, the wire feeding wheel 7. Move the front end of the wire into the knife holder 12, the motor 14 drives the upper blade 15 to move down and the lower blade 16 to cut the wire, the motor 14 raises the upper blade 15, the wire feeding wheel 7 pushes the wire forward to the stripping distance, and the upper blade 15 Move down, pull the wire after the wire feeding wheel 7 to complete the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com