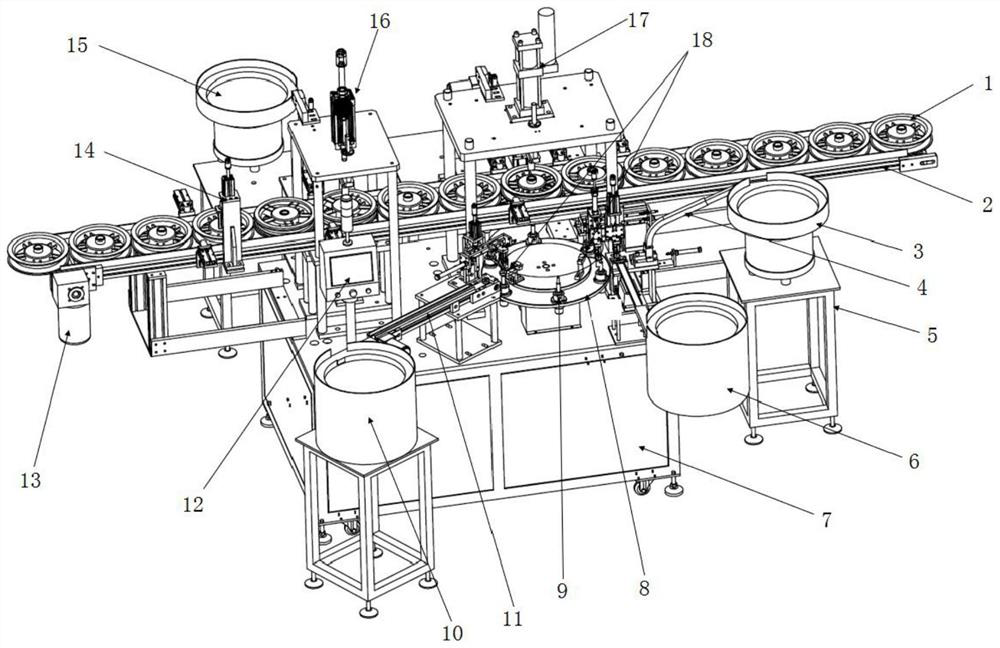

Automatic press-fitting equipment for hub bearing of electric bicycle

A technology for electric bicycles and hub bearings, applied in metal processing equipment, assembly machines, metal processing, etc., can solve the problems of increased labor, low assembly efficiency, and unstable assembly quality, so as to reduce labor and increase assembly efficiency , Guarantee the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

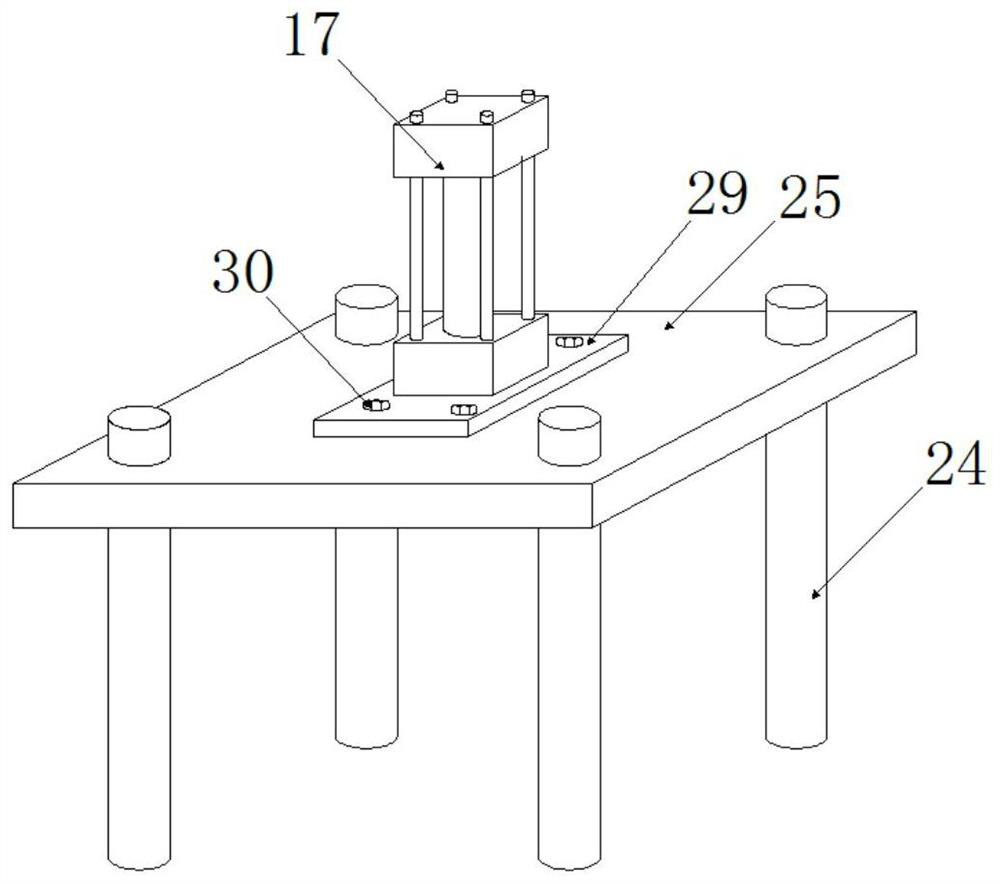

[0022] In the present invention, the middle part of the upper end of the first horizontal plate 25 is detachably connected with a fixed plate 29 by four screws 30, and the pressure bearing cylinder 17 is fixedly installed on the fixed plate 29, and the operator can conveniently press the pressure bearing cylinder through the fixed plate 29. 17 is disassembled, so that the pressure bearing cylinder 17 is more convenient when changing.

[0023] In the present invention, the telescopic end of the pressure bearing cylinder 17 runs through the fixed plate 29 and the first horizontal plate 25 and is correspondingly arranged above one of the parts 1 to be fixed. Through the operation of the pressure bearing cylinder 17, the parts can be pressed onto the hub Inside, realize the effect of pressing, the left side of pressure bearing cylinder 17 is provided with pressure oil seal cylinder 16, pressure oil seal cylinder 16 is connected with supporting parts, is convenient to stable operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com