Linear stator vibration motor adopting vacuum resin filling and sealing, and assembling and manufacturing methods of linear stator vibration motor

A technology of vibrating motors and wire stators, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of motors that are prone to turn-to-turn problems, and achieve the effects of improving quality, reducing turn-to-turn, and leaving no air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

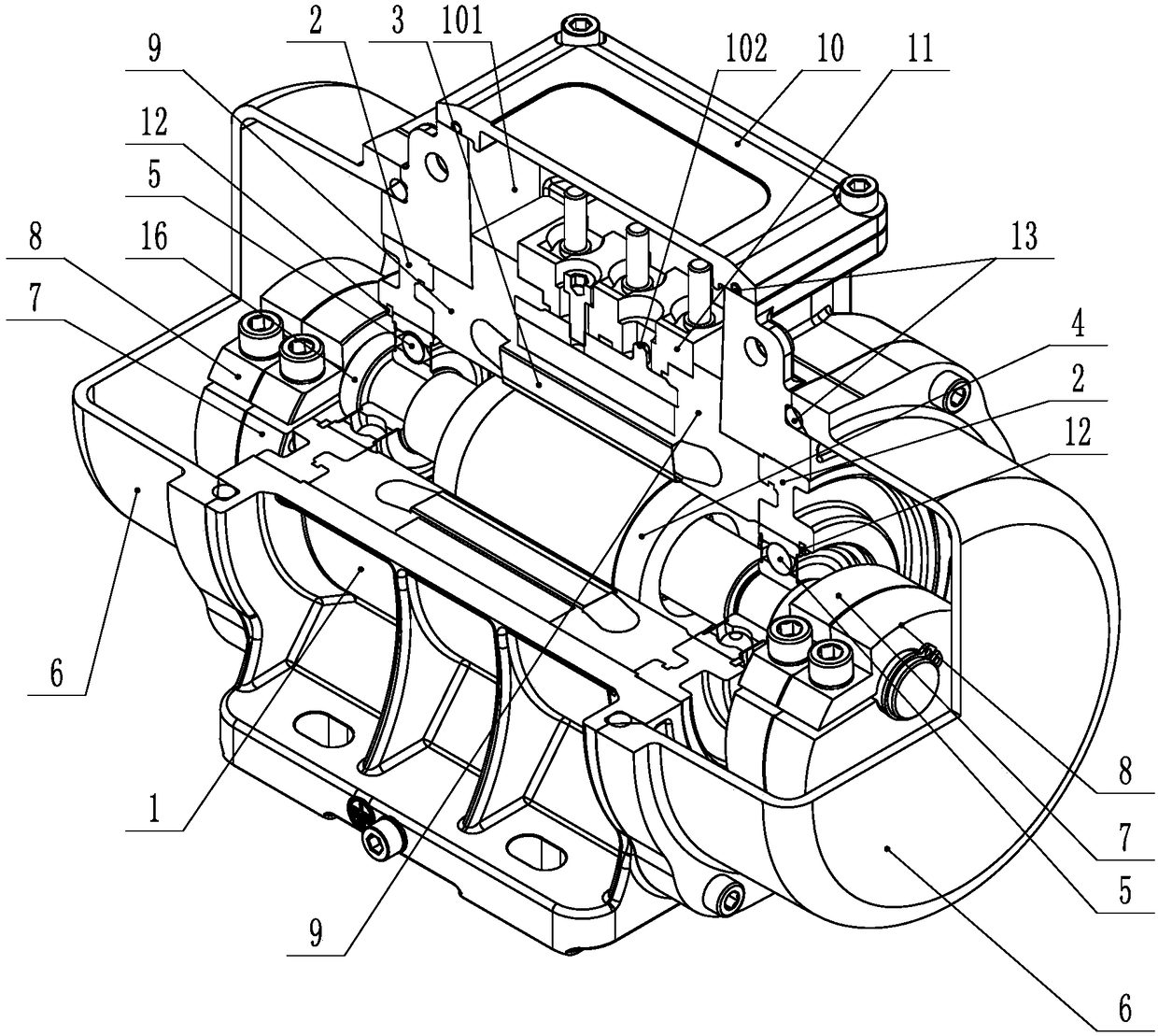

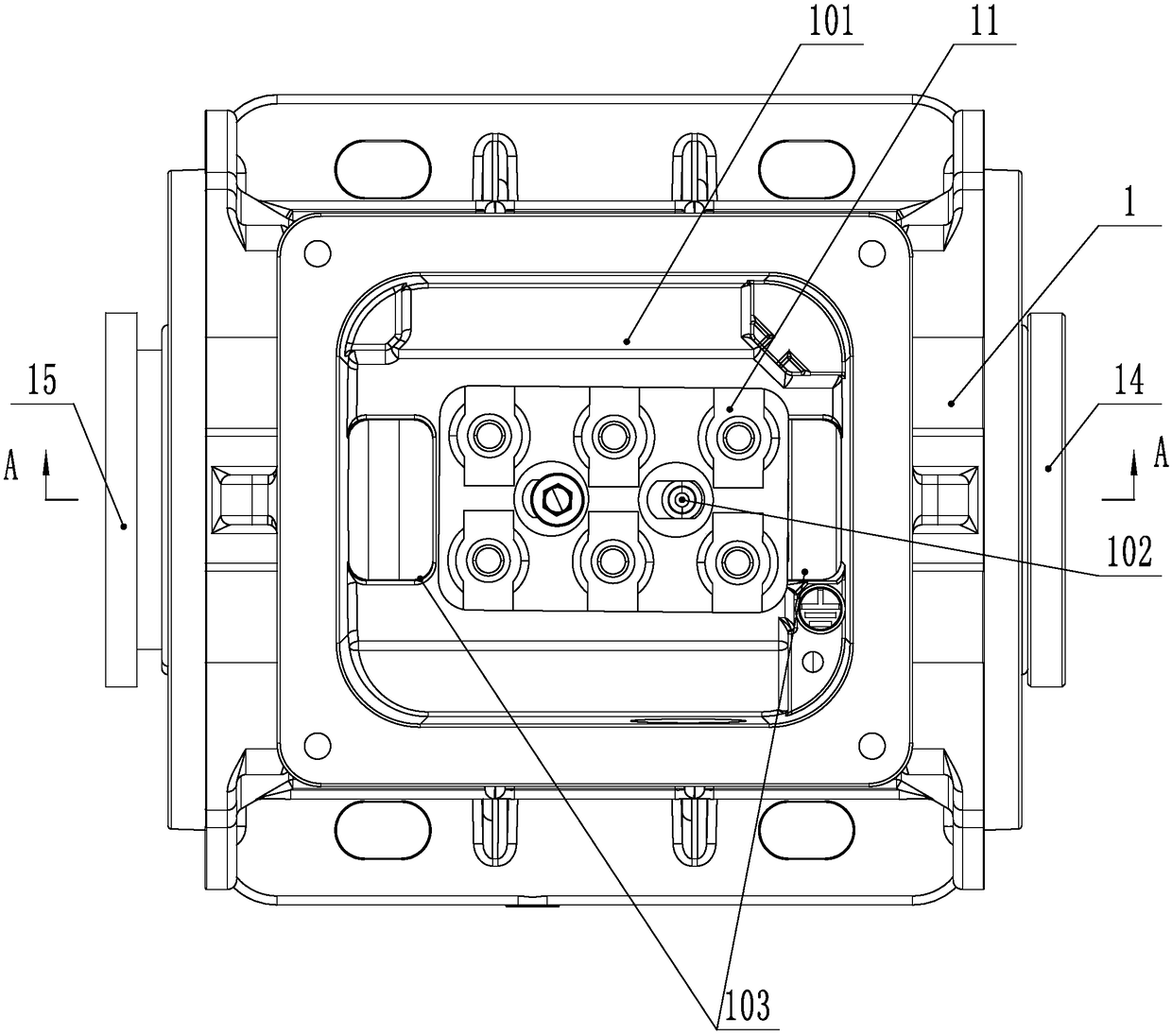

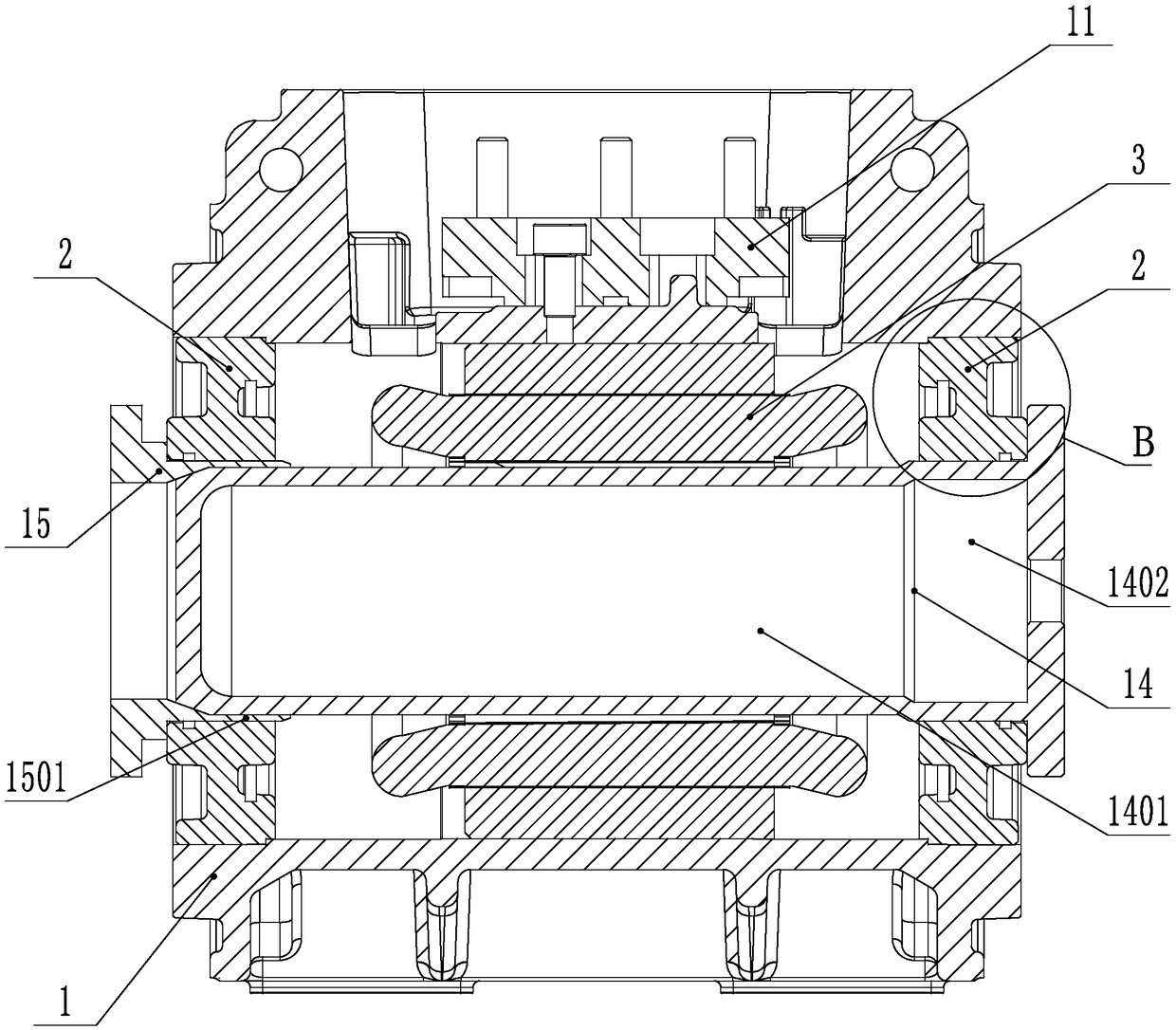

[0039] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0040] Such as Figure 1-4 As shown, a stator vibrating motor adopts vacuum resin potting wire, including a frame 1, an end cover 2 matching the end holes at both ends of the frame 1, a winding stator core 3 internally pressed on the frame 1, and a rotor 4 , the bearing 5 internally pressed in the bearing chamber of the end cover 2, the eccentric block arranged at both ends of the rotor 4, the end cover 6 arranged at both ends of the frame 1, the frame 1 is provided with a junction box, and the eccentric block includes an active eccentric block 7 and The driven eccentric block 8 is provided with insulating resin 9 for vacuum potting in the space surrounded by the inner wall of the base 1, the end caps 2 at both ends of the base 1 and the inner diameter position of the winding stator core 3.

[0041] In order not to cause damage when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com