T-fitting

A technology of three-way pipe and main pipe, which is applied in the direction of pipe connection arrangement, pipe/pipe joint/pipe fitting, household components, etc., to achieve the effect of improving pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

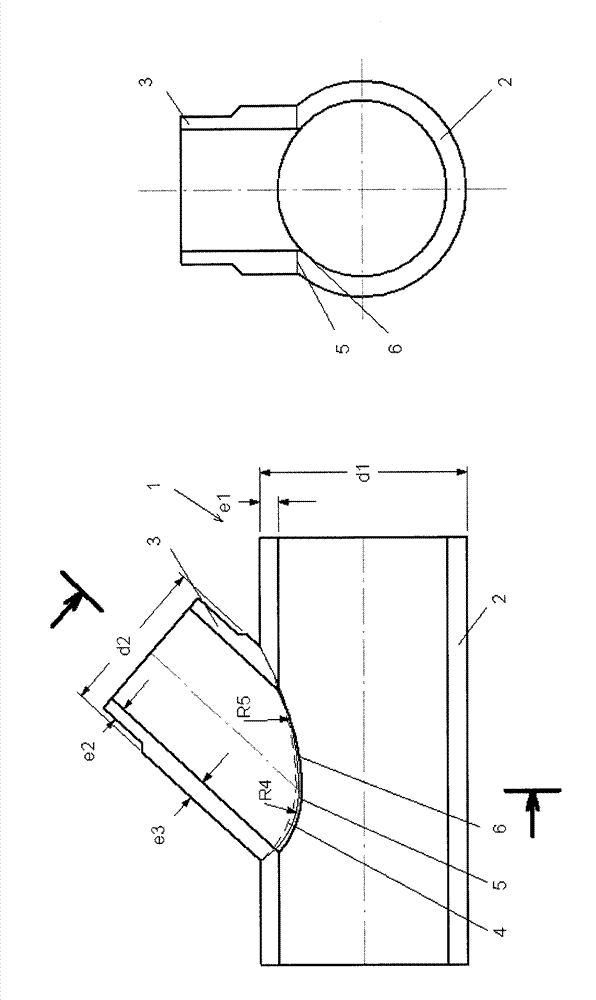

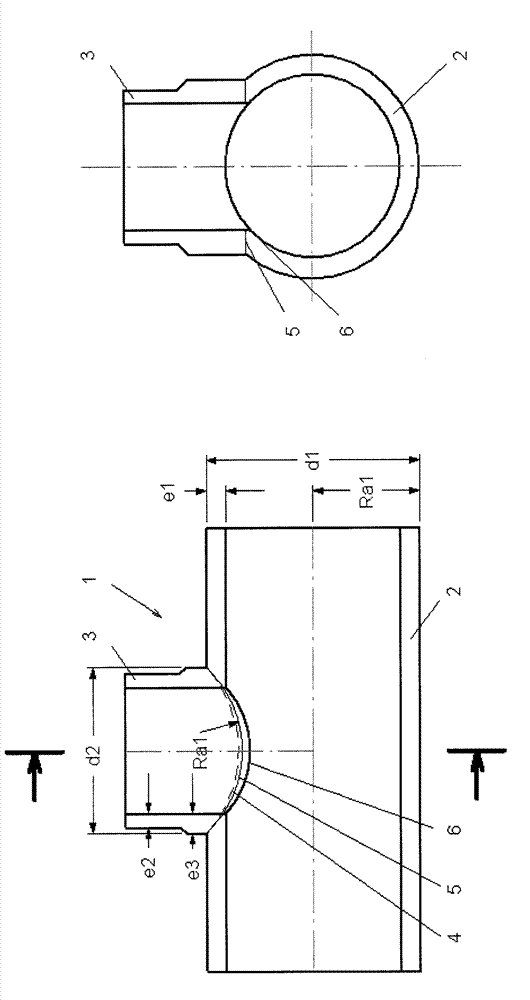

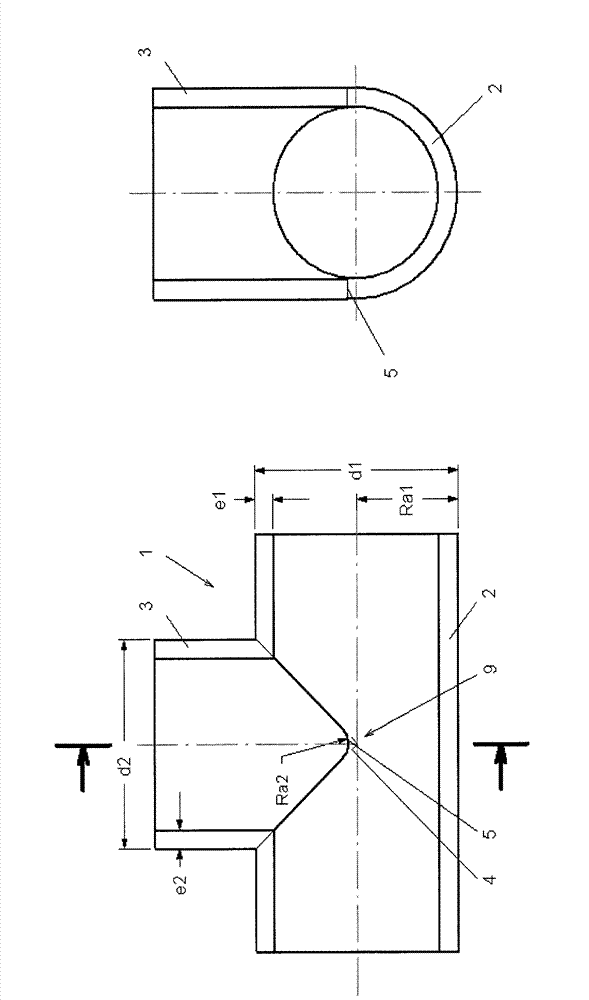

[0046] figure 1 A welded tee 1 is shown with a branch 3 extending at a 90° angle to the main pipe 2 or joined perpendicularly to the main pipe 2 . The diameter d2 of the branch pipe 3 does not match the diameter d1 of the main pipe 2 . Thus, in figure 1 It is shown that tubes 2, 3 having different diameters d1, d2 are welded together. In order to form a good weld, it is advantageous that the wall thicknesses e1 , e3 are approximately equal in the region of the weld, resulting in the same joint pressure conditions. Furthermore, the widened wall thickness leads to increased strength. It is therefore advantageous to make the wall thickness of the pipes to be joined together or to adapt it, for example by increasing the wall thickness e3 in the branch pipe 3, as figure 1 shown. The theoretical line of intersection 4 that would appear when joining the two pipes 2, 3 together is at figure 1 is shown by dashed line 4. The approximate intersecting line 5 is obtained from the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com