Capacitive touch switch with metal material

A capacitive touch, metal material technology, applied in electronic switches, electrical components, pulse technology, etc., can solve the problems of insensitive operation, inability to recognize capacitance changes, prone to false triggering, etc., to solve the problem of false triggering or insensitive operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

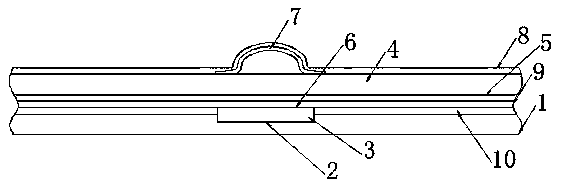

[0020] like figure 1 As shown, this embodiment adopts the following technical solutions:

[0021] A capacitive touch switch with metal materials includes a key line 1, a lower electrode 3, a diaphragm 4, a double-sided adhesive layer 5, an upper electrode 7 and a protective film 8. The upper end of the key line 1 is provided with a first half groove 2, so A lower electrode 3 is arranged in the first half groove 2, a diaphragm 4 is arranged above the button circuit 1, and a double-sided adhesive layer 5 is arranged between the diaphragm 4 and the button circuit 1, and the double-sided adhesive layer 5 is close to A second half-groove 6 is provided on one side of the lower electrode 3, and the specifications of the second half-groove 6 are consistent with the specifications of the first half-groove 2, and are distributed axially symmetrically about the overlapping line of the first half-groove 2 and the second half-groove 6. The upper end of the diaphragm 4 is provided with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com