Water-cooling electric charger

A technology for electric vehicles and chargers, applied to electric vehicles, current collectors, battery circuit devices, etc., can solve problems such as easy access, short circuit, and potential safety hazards, and achieve the effect of improving heat absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

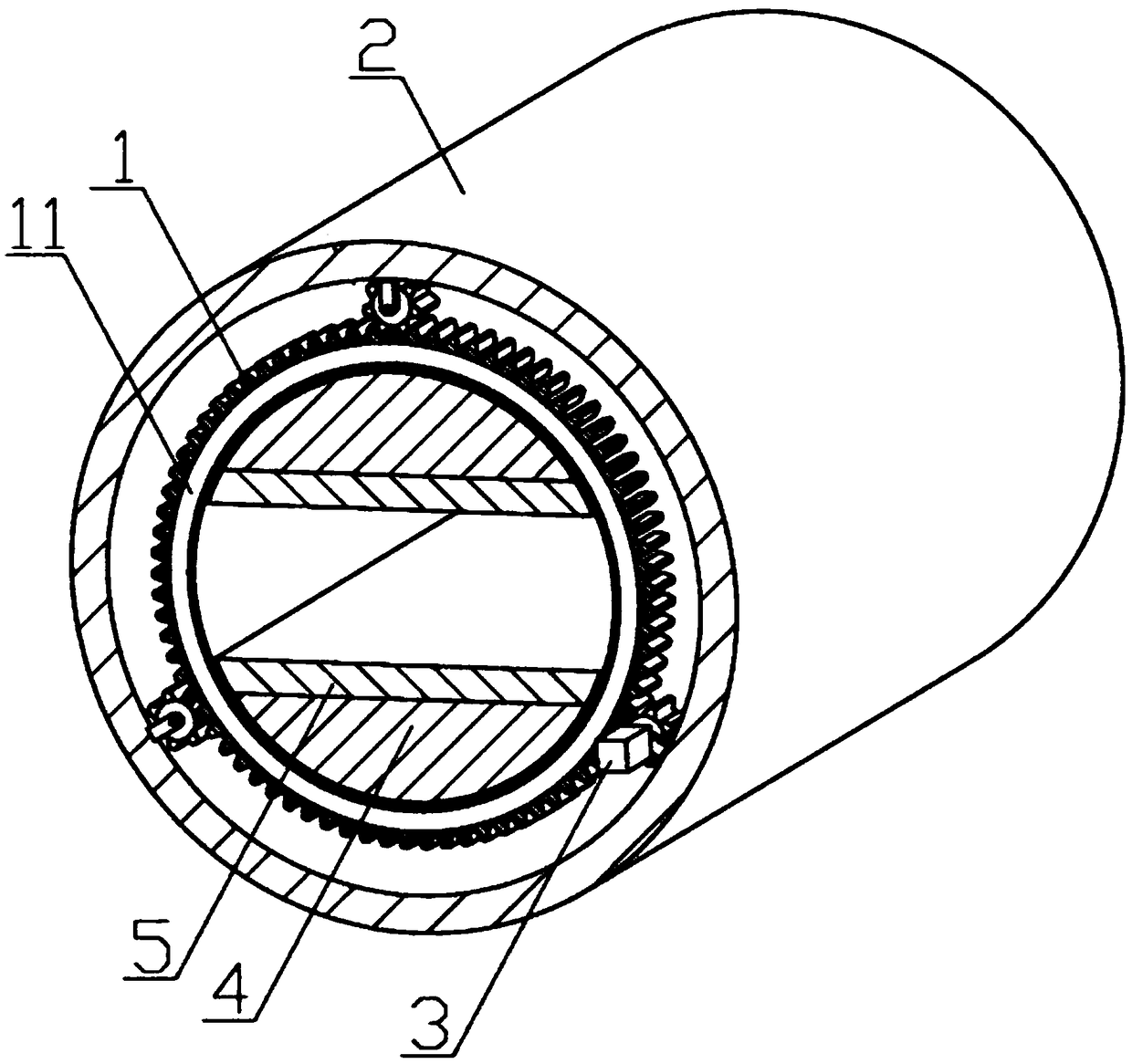

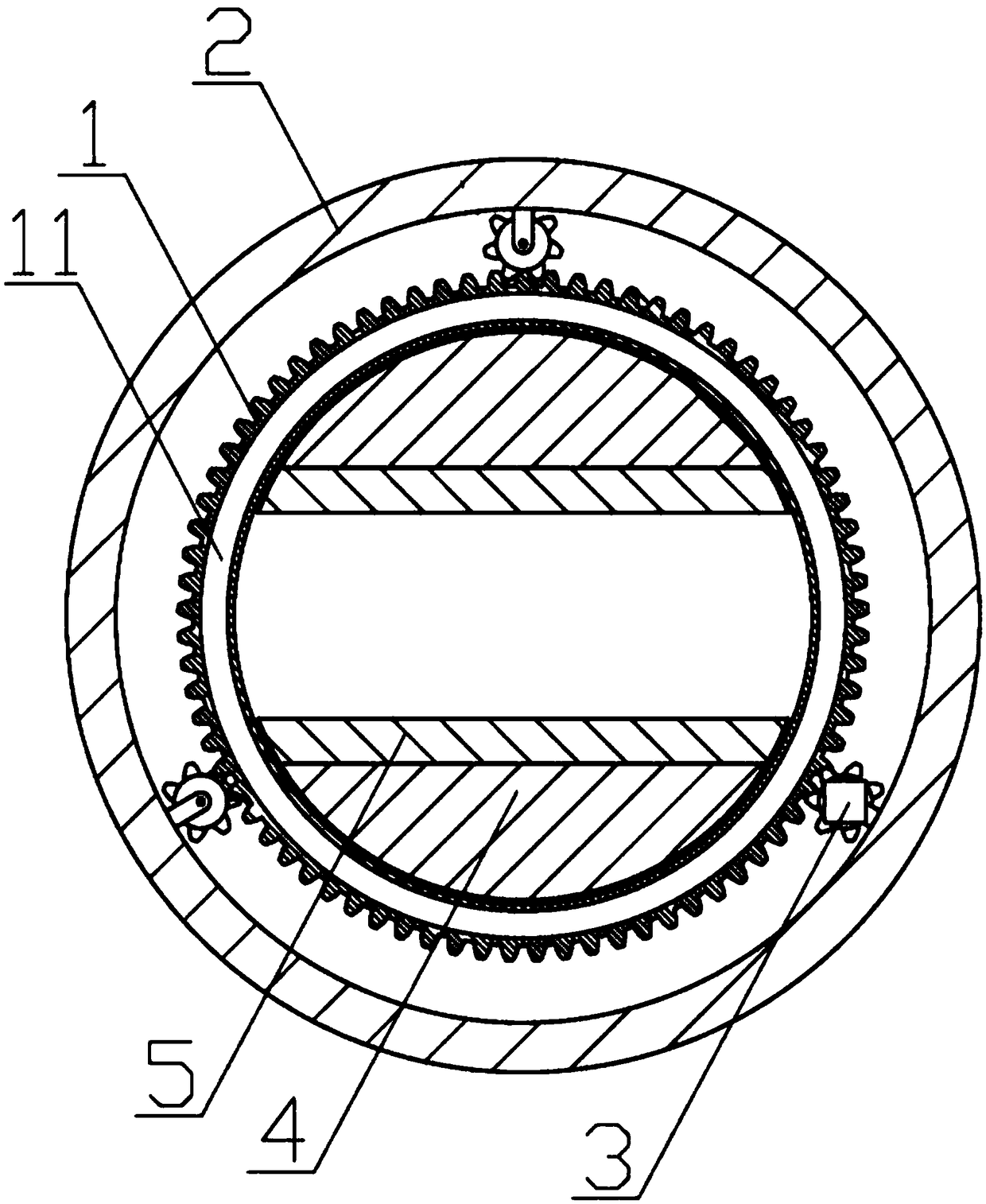

[0017] Such as Figure 1-2 as shown, figure 1 It is an axonometric view of the internal structure of a water-cooled electric vehicle charger proposed by the present invention, figure 2 It is a front view of the internal structure of a water-cooled electric vehicle charger proposed by the present invention.

[0018] refer to Figure 1-2 , a water-cooled electric vehicle charger proposed by the present invention, including a water-cooled part 1, a housing 2, a motor 3, a heat-conducting part 4, a heat-conducting silica gel sheet 5 and electrical components;

[0019] The housing 2 is cylindrical, and one end of the housing 2 is provided with an opening, and an end cover is detachably installed on the opening. After the end cover is installed on the opening, the inside of the housing 2 is sealed, and the housing 2 is not provided with cooling holes; 1 is made of copper material, and the water-cooling part 1 is also in the shape of a cylinder, and both ends of the water-cooling...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap