Double-layer roll crusher device

A roller crusher and double-layer roller technology, which is applied in the field of hard material equipment and particle crushing equipment, can solve the problems of not being able to meet various specifications of raw materials, uncontrollable feeding volume, poor synchronization of crushing rollers, etc., to achieve Meet the particle size requirements of finished products, low power consumption, and good feeding uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment

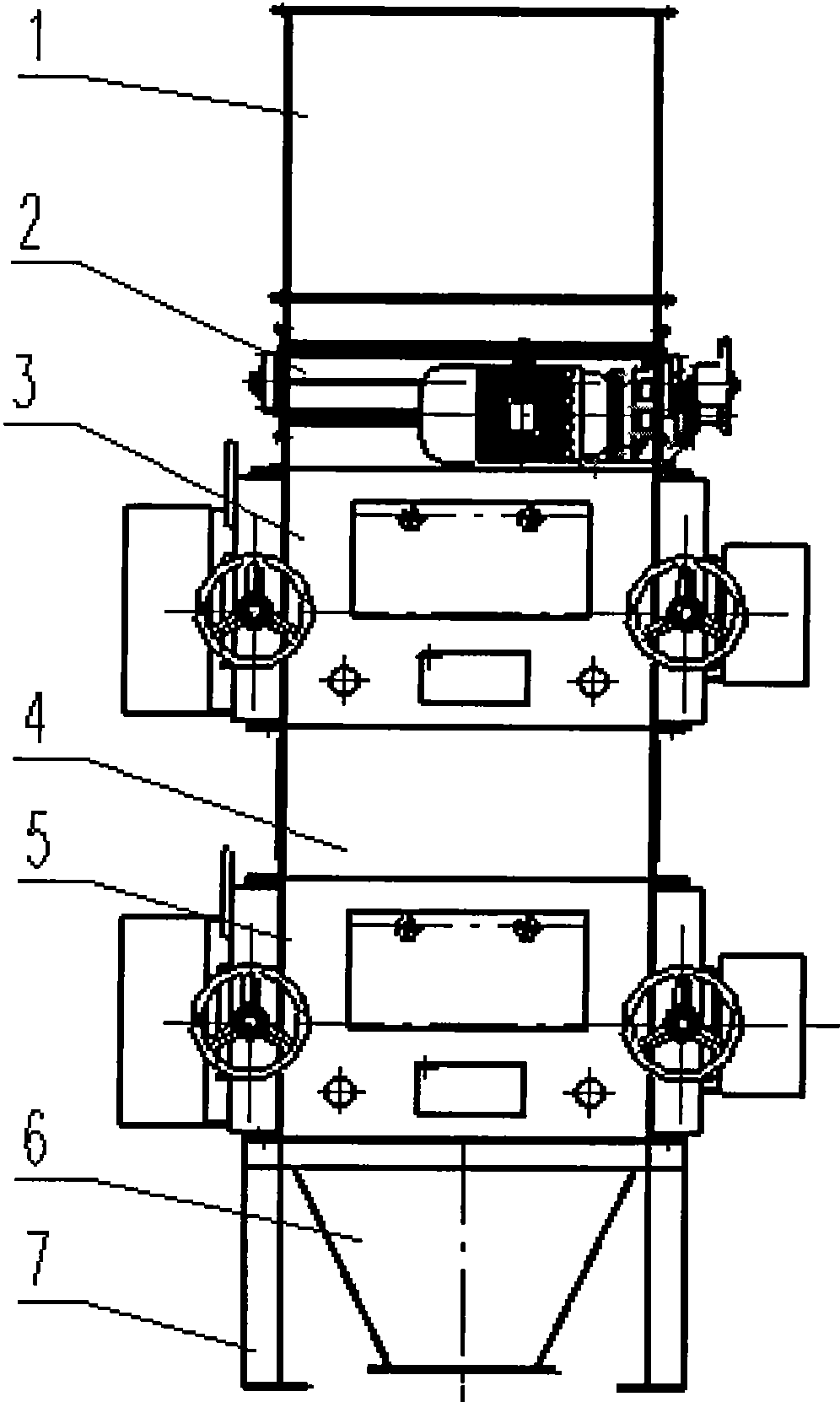

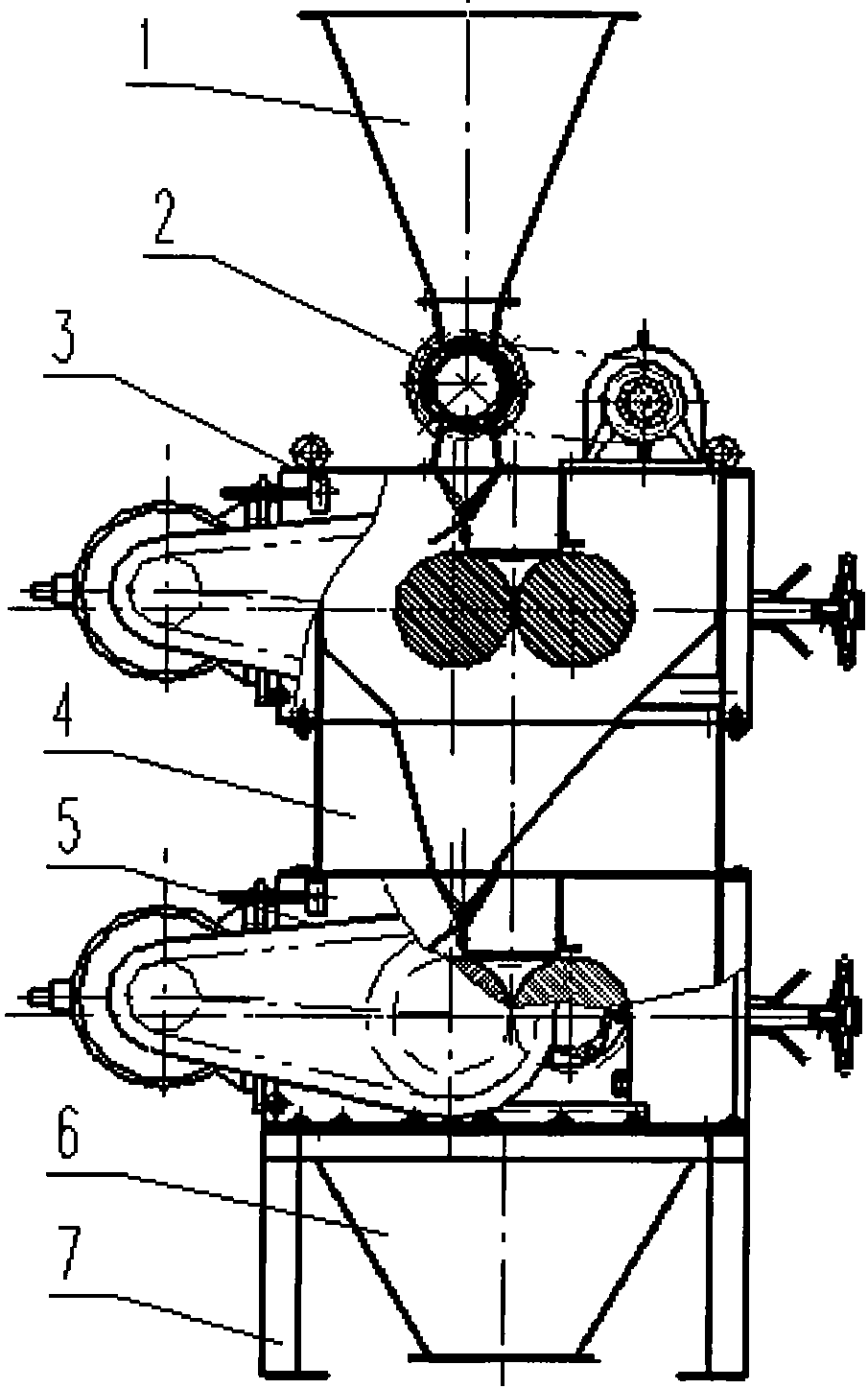

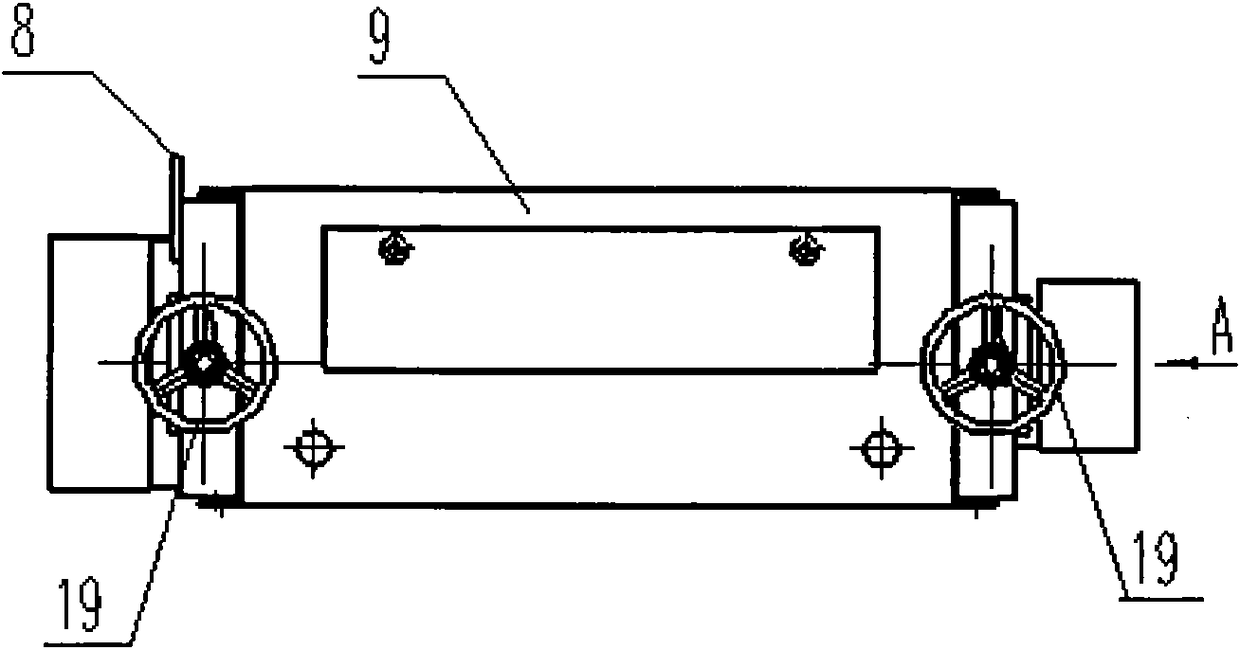

[0028] With reference to the accompanying drawings, a double-layer roller crusher device includes a feed hopper 1, a feeder 2, an upper roller crusher 3, a connecting frame 4, a lower roller crusher 5, a discharge hopper 6, and a frame 7. The feeding hopper 1 is installed above the inlet of the feeder 2, and the lower outlet is connected to the inlet of the upper roller crusher 3, and then connected with the inlet of the lower roller crusher 5 by the connecting frame 4, and then supported on the frame 7, and the outlet The hopper 6 is connected to the outlet of the lower roller crusher 5 .

[0029] The feeder 2 is composed of a speed regulating motor 29, a sprocket 28, a chain 32, a feeding casing 30, and a feeding roller 31. The feeding roller 31 is installed on the feeding casing 30, and the sprocket 28 is installed on the feeding roller. One end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com