Preparation method of high-impedance iron-silicon material and integrated inductor containing the iron-silicon material

A high-impedance, iron-silicon technology, applied in the field of inductors, can solve the problems of shortening the service life of integrated inductors, easily generating microcracks, poor insulation performance, etc., to improve DC superposition performance, improve coating effect, and good insulation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

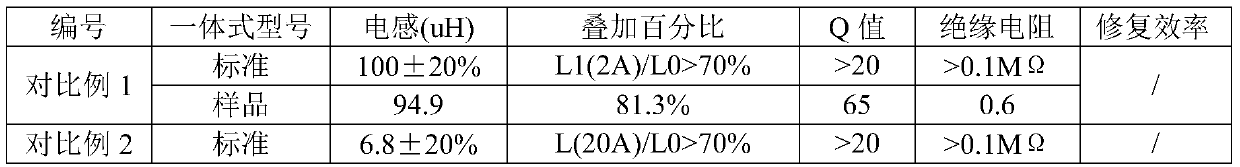

Examples

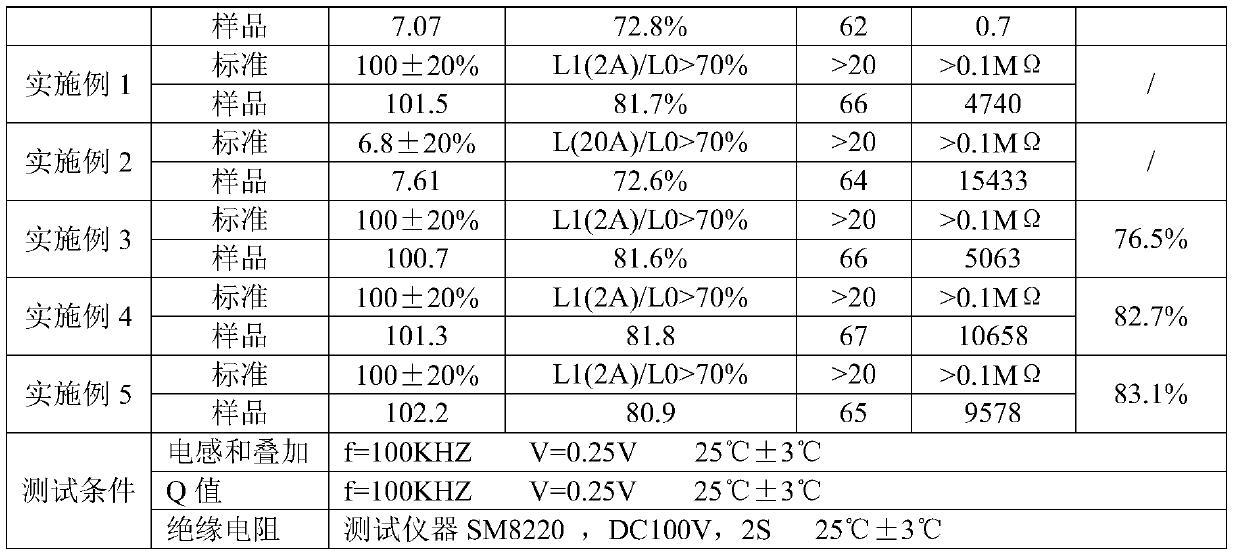

Embodiment 1

[0039] Powder selection and processing: choose water-atomized iron-silicon powder with a particle size of 400 mesh, and perform ball milling for 30 minutes;

[0040]Insulation coating: Slowly pour 30g of phosphoric acid, 5g of aluminum dihydrogen phosphate and 5g of chromic acid into 1.2kg of acetone and stir for more than 1 minute to dilute completely to obtain a coating solution, which is added to 10kg of water atomized iron silicon Stir in the powder evenly, soak for 5 minutes, then stir for 30 minutes, dry the powder in the air for 3 hours in a ventilated environment, sieve through a 50-mesh sieve, and then bake in an oven at 100°C for 1 hour;

[0041] Secondary coating: Mix 200g of silicone resin and 100g of liquid glue evenly, let stand for 5min, stir for 1min, add 1kg of acetone to dilute and stir evenly for 10min, then filter the solution with 200 mesh to remove impurities, and obtain Secondary coating solution, add the secondary coating solution to the water atomized ...

Embodiment 2

[0045] Powder selection and processing: choose water-atomized iron-silicon powder with a particle size of 500 mesh, and perform ball milling for 60 minutes;

[0046] Insulation coating: Slowly pour 15g of phosphoric acid and 5g of potassium water glass into 1.3kg of acetone and stir for more than 1 minute to dilute completely to obtain a coating solution, add the coating solution to 10kg of water atomized iron-silicon powder and stir evenly , soaked for 10 minutes, then stirred for 60 minutes, dried the powder in the air for 4 hours in a ventilated environment, sifted through a 50-mesh screen, and then baked in a 90°C oven for 2 hours;

[0047] Secondary coating: Mix 100g silicone resin and 100g liquid glue evenly, let stand for 15min, stir for 1min, add 1.1kg of acetone to dilute and stir evenly, let stand for 10min, then filter the solution with 200 mesh to remove impurities, and make To obtain the secondary coating solution, add the secondary coating solution into the water...

Embodiment 3

[0051] Powder selection and processing: choose water-atomized iron-silicon powder with a particle size of 400 mesh, and perform ball milling for 30 minutes;

[0052] Insulation coating: Slowly pour 30g of phosphoric acid, 5g of aluminum dihydrogen phosphate and 5g of chromic acid into 1.2kg of acetone and stir for more than 1 minute to dilute completely to obtain a coating solution, which is added to 10kg of water atomized iron silicon Stir in the powder evenly, soak for 5 minutes, then stir for 30 minutes, dry the powder in the air for 3 hours in a ventilated environment, sieve through a 50-mesh sieve, and then bake in an oven at 100°C for 1 hour;

[0053] Preparation of microcapsules: add 0.2g sodium dodecylbenzenesulfonate to 300mL deionized water, stir for 20min; After stirring until dissolved, adjust the pH of the solution to 2.0 with sodium hydroxide and hydrochloric acid solution; add 5g of bisphenol A epoxy resin E-54 and 5g of trimethylolpropane triglycidyl ether to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com