A kind of alloy powder preparation method of recycling copper chromium alloy

A kind of alloy powder, copper-chromium alloy technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

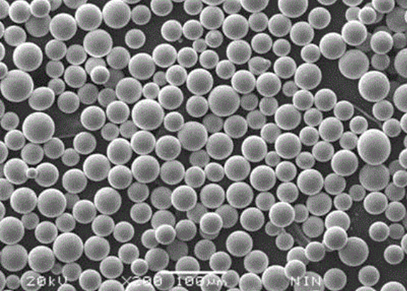

Image

Examples

Embodiment 1

[0026] Embodiment 1: a kind of copper-chromium alloy reclaims the alloy powder preparation method of recycling, comprises the following steps:

[0027] S1: Washing and drying

[0028] First use high-pressure water to wash the impurities adhered to the surface of CuCr alloy scraps, then use ultrasonic cleaning to remove surface oil and oxide layers, and finally dry them;

[0029] S2: vacuum induction melting

[0030] The CuCr alloy scrap that step S1 obtains is put into the crucible of smelting chamber, and wherein crucible material is magnesium oxide; Wait until vacuum degree reaches 10 -1 Pa, start heating; the heating power gradient increases, 40kW for 3 minutes, 60kW for 3 minutes, and finally rise to 80kW. When the CuCr alloy in the crucible starts to melt, turn off the vacuum system, reduce the heating power to 20kW, and then fill it with argon to the standard Atmospheric pressure; preheat the tundish, keep the power of the heating device at 7kW, and then increase the h...

Embodiment 2

[0037] Embodiment 2: a method for preparing copper-chromium alloy reclaimed alloy powder, comprising the following steps:

[0038] S1: Washing and drying

[0039] First use high-pressure water to wash the impurities adhered to the surface of CuCr alloy scraps, then use ultrasonic cleaning to remove surface oil and oxide layers, and finally dry them;

[0040] S2: vacuum induction melting

[0041] Put the CuCr alloy scraps obtained in step S1 into the crucible of the smelting chamber, wherein the material of the crucible is calcium oxide; until the vacuum degree reaches 10 -1 Pa, start heating; the heating power gradient increases, 40kW for 4min, 60kW for 4min, and finally rise to 80kW, when the CuCr alloy in the crucible starts to melt, turn off the vacuum system, reduce the heating power to 20kW, and then fill it with argon to the standard Atmospheric pressure; preheat the tundish, keep the power of the heating device at 18kW, and then increase the heating power to 125kW to ...

Embodiment 3

[0048] Embodiment 3: a kind of alloy powder preparation method of copper-chromium alloy recycling, comprises the following steps:

[0049] S1: Washing and drying

[0050] First use high-pressure water to wash the impurities adhered to the surface of CuCr alloy scraps, then use ultrasonic cleaning to remove surface oil and oxide layers, and finally dry them;

[0051] S2: vacuum induction melting

[0052] Put the CuCr alloy scraps obtained in step S1 into the crucible of the smelting chamber, wherein the material of the crucible is zirconia; until the degree of vacuum reaches 10 -1 Pa, start heating; the heating power gradient increases, 40kW for 5min, 60kW for 5min, and finally rise to 80kW, when the CuCr alloy in the crucible starts to melt, turn off the vacuum system, reduce the heating power to 20kW, and then fill it with argon to the standard Atmospheric pressure; preheat the tundish, keep the power of the heating device at 30kW, and then increase the heating power to 150...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com