Constant-temperature heating platform for vulcanization

A constant temperature heating and platform technology, applied in the field of vulcanization heating, can solve the problems of large temperature difference between the steam inlet and the steam outlet, difficulty in achieving constant temperature heating, and increased temperature difference of the heating platform, so as to reduce maintenance costs, avoid heat loss and temperature fluctuations , maintain a consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

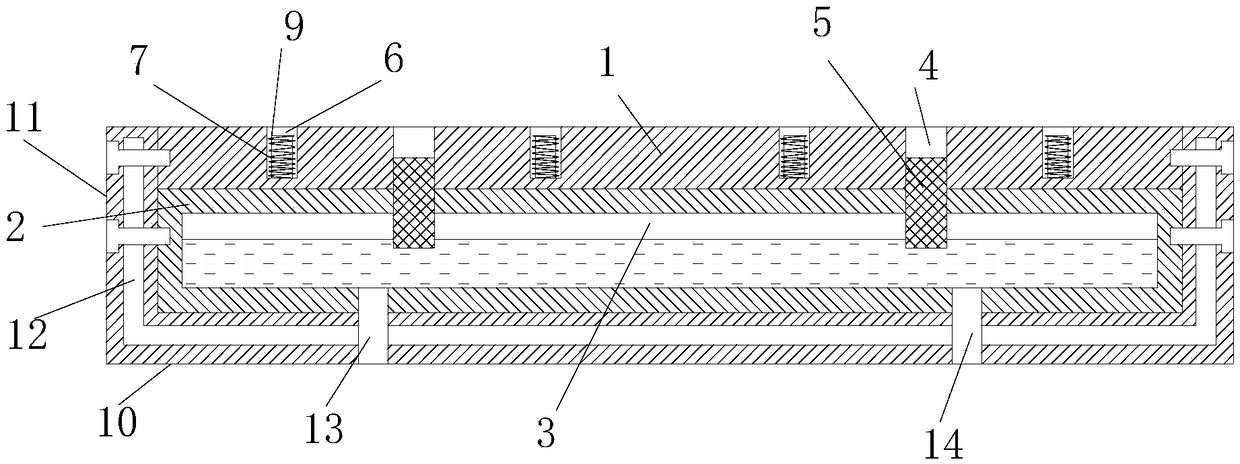

[0017] refer to figure 1 , figure 2 , the present invention proposes a vulcanization constant temperature heating platform, including a heating platform, which includes a first plate 1, a second plate 2 and a third plate 10 arranged in sequence from top to bottom.

[0018] The second plate body 2 is provided with a constant temperature oil chamber 3, and the constant temperature oil chamber 3 is filled with constant temperature hot oil.

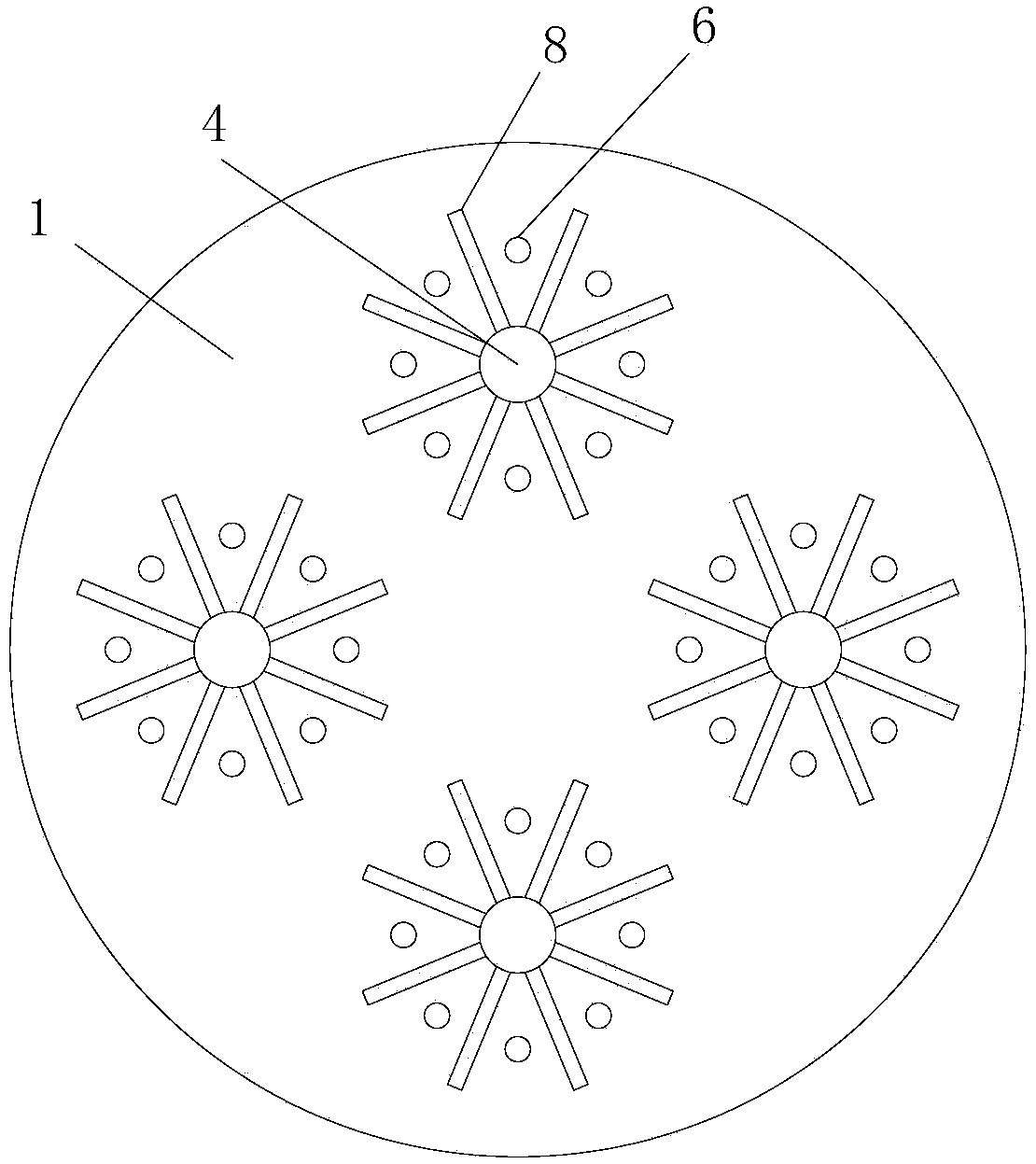

[0019] The first plate body 1 is provided with a plurality of heat conduction holes 4 passing through its upper and lower surfaces and communicating with the constant temperature oil chamber 3. The heat conduction holes 4 are provided with heat conduction columns 5 extending into the constant temperature hot oil, and the heat conduction columns 5 are far away from the second plate. One end of the body 2 does not exceed the first plate body 1, and the heat conduction column 5 is adapted to the heat conduction hole 4 and is sealed and connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com