Electronic winder

A wire winder and electronic technology, applied in the field of sewing, can solve problems such as winding speed, uneven tension, inability to independently wind, and inability to perform winding operations, etc., to achieve compact structure, flexible and convenient use, and increased output The effect of torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

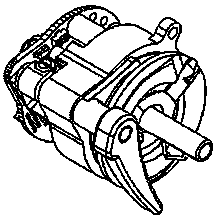

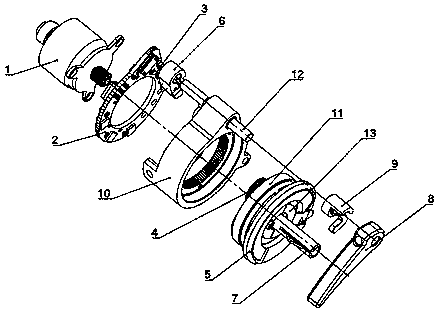

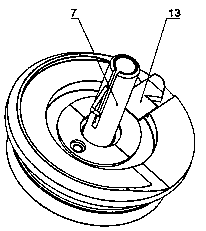

[0022] Below in conjunction with accompanying drawing, structure of the present invention is described in detail:

[0023] The working principle of the present invention is: driven by the winding motor, decelerated by the planetary reduction mechanism, driving the winding base to rotate for winding operation, wherein the winding motor can be divided into starting winding, high-speed winding and low-speed according to different stages of winding operation Winding, the end of the winding automatically adjusts the winding speed. The principle is to sense the different stages of the winding operation through the mechanism composed of its own Hall sensor, induction magnet, winding wrench, and winding wrench shaft, and then transmit the signal to the The motor drive board, the motor drive board controls the speed of the winding motor according to the signal, and realizes the functions of automatic start-stop and speed change.

[0024] The invention provides an electronic wire winder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com