Bypass valve of engine oil filter

An oil filter and bypass valve technology, which is applied in the direction of machine/engine, mechanical equipment, engine components, etc., can solve the problems of non-adjustable bypass valve pressure and large pressure tolerance, so as to improve accuracy, prolong service life, Adjustable opening pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

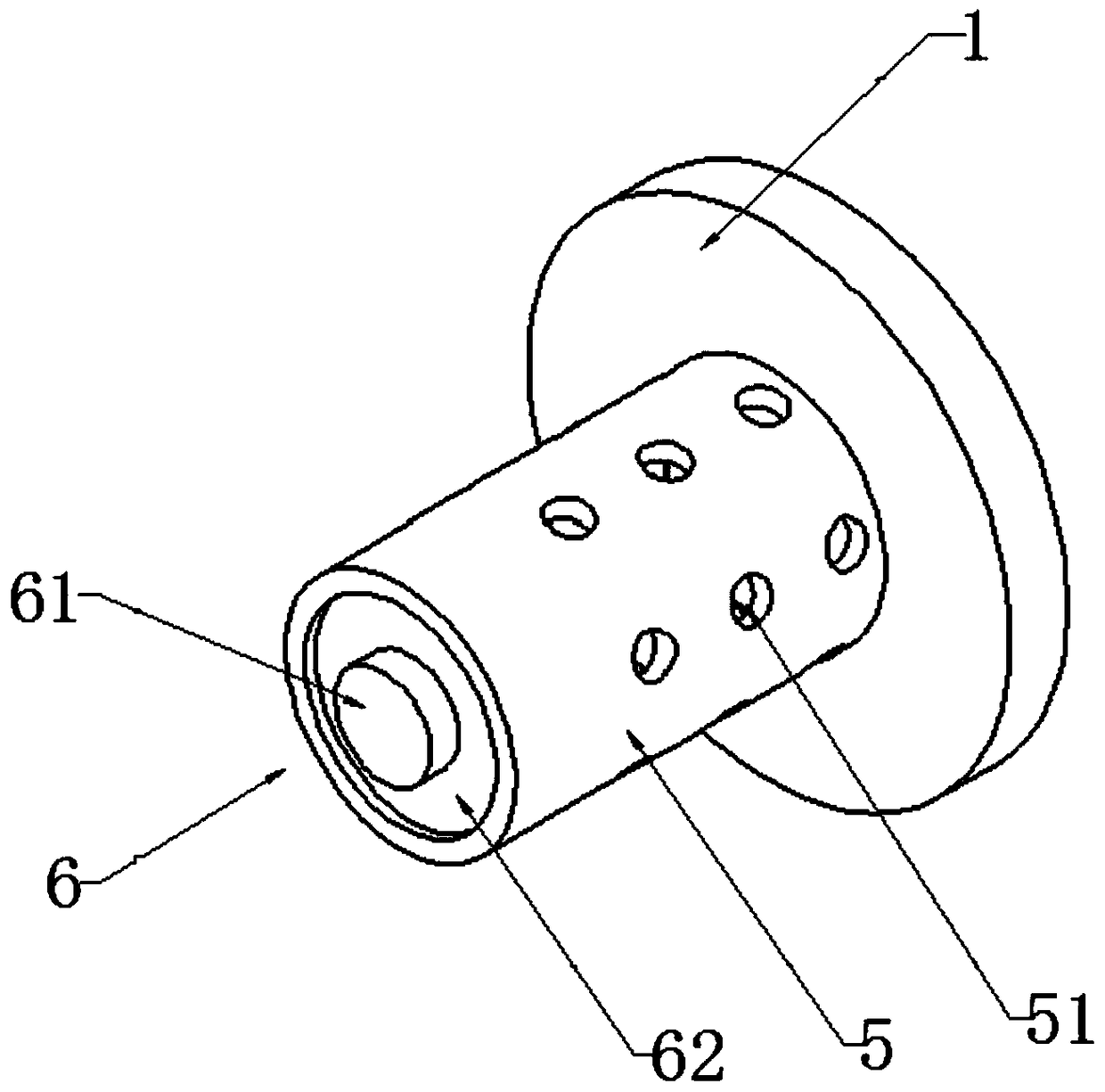

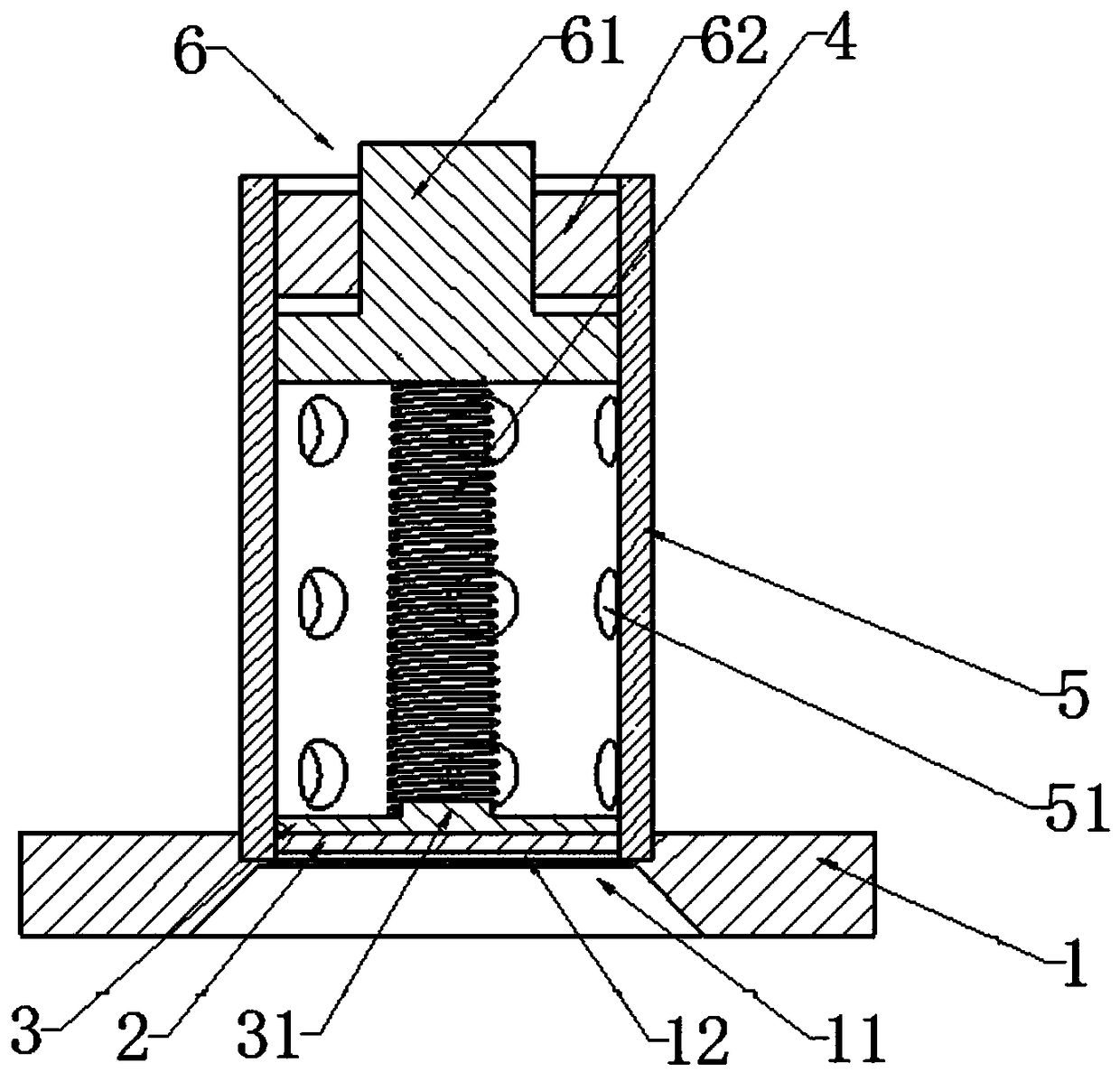

[0023] Embodiment 1 discloses an oil filter bypass valve, such as figure 1 and figure 2 As shown, it includes an end cover 1, a gasket 2, a gasket 3, a spring 4, a valve body 5 with a circular tube structure, and a pressure adjustment unit 6. The end cover 1 is riveted with the valve body 5, and the gasket 2 is placed on the valve body 1. At the bottom, the thickness of the gasket 2 is set to 2mm, and the diameter of the gasket 2 is larger than the diameter of the oil inlet 11 of the end cover 1. The oil inlet 11 is also fixedly covered with a layer of nylon cloth 12, and the nylon cloth 12 is uniformly staggered with The first filter hole (not marked in the figure) and the second filter hole (not marked in the figure), the aperture of the first filter hole (not marked in the figure) is set to 0.05mm, the second filter hole (not marked in the figure) The aperture was set to 0.8mm.

[0024] The gasket 3 is installed on the top of the gasket 2, the gasket 3 is made of stainle...

Embodiment 2

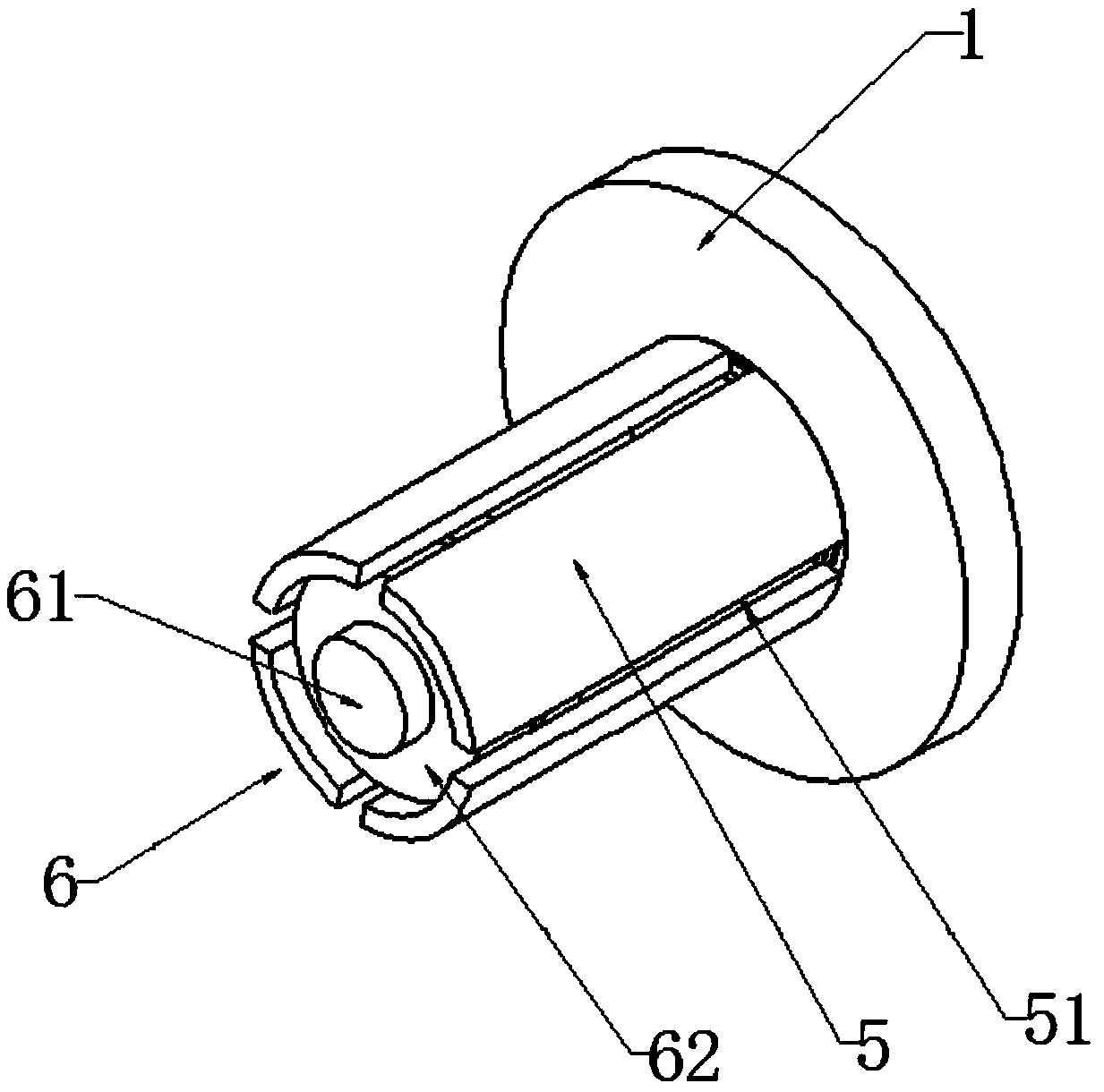

[0028] Embodiment 2 discloses an oil filter bypass valve, such as image 3 and Figure 4 As shown, it includes an end cover 1, a gasket 2, a gasket 3, a spring 4, a valve body 5 with a circular tube structure, and a pressure adjustment unit 6. The end cover 1 is riveted with the valve body 5, and the gasket 2 is placed on the valve body 1. At the bottom, the thickness of the gasket 2 is set to 3mm, the diameter of the gasket 2 is greater than the diameter of the oil inlet 11 of the end cover 1, and the oil inlet 11 is fixedly covered with a layer of nylon cloth 12, and the nylon cloth 12 is evenly staggered with The first filter hole (not marked in the figure) and the second filter hole (not marked in the figure), the aperture of the first filter hole (not marked in the figure) is set to 0.1mm, the second filter hole (not marked in the figure) The aperture is set to 1.2mm.

[0029] The gasket 3 is installed on the top of the gasket 2, the gasket 3 is made of stainless steel ...

Embodiment 3

[0033] Embodiment 3 discloses an oil filter bypass valve, which includes an end cover 1, a gasket 2, a gasket 3, a spring 4, a valve body 5 with a circular tube structure, and a pressure adjustment unit 6. The end cover 1 and the valve body 5 Riveting, the gasket 2 is placed on the bottom of the valve body 1, the thickness of the gasket 2 is set to 2-3mm, and the diameter of the gasket 2 is larger than the diameter of the oil inlet 11 of the end cover 1. The gasket 3 is installed on the top of the gasket 2, the gasket 3 is made of stainless steel or electro-galvanized sheet material, the spring 4 is installed on the top of the gasket 3, the bottom of the pressure adjustment unit 6 is pressed against the spring 4 and the pressure adjustment unit 6 and the inner circumference of the valve body 5 are pressed and fixed, and the valve body 5 is evenly provided with an oil outlet mechanism 51, and the oil outlet mechanism 51 is an oil outlet hole with a diameter of 1 mm; the pressure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com