Continuous vacuum insulation double-wall pipe

A technology of vacuum heat insulation and double-wall pipes, applied in the field of double-wall pipes, can solve the problems of difficult detection of pipeline leakage, damage, and easy aging, and achieve the effects of avoiding uncontrollable leakage, avoiding direct contact, and avoiding aging damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

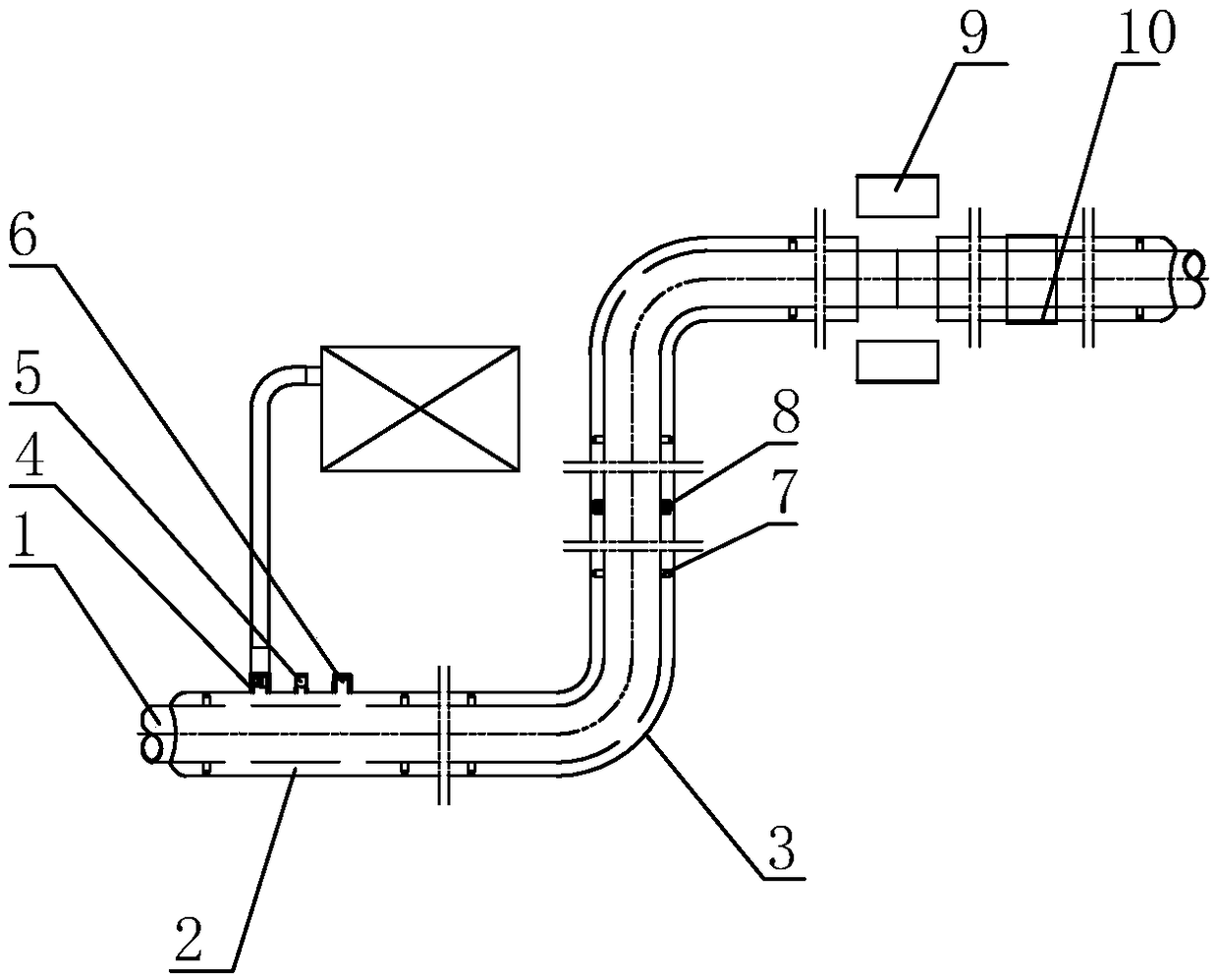

[0017] refer to Figure 1 to Figure 3 The embodiment of the continuous vacuum insulated double-wall pipe of the present invention will be further described.

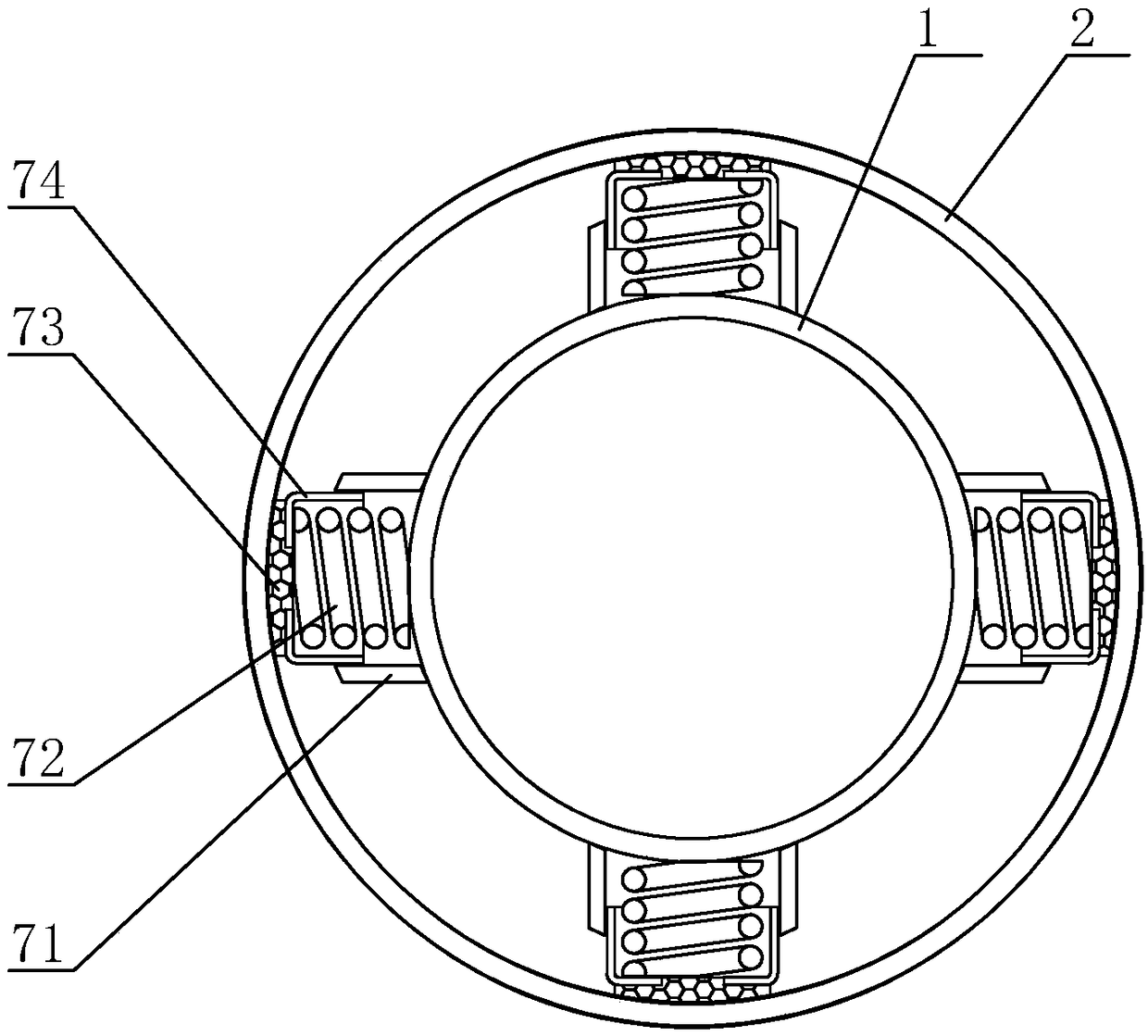

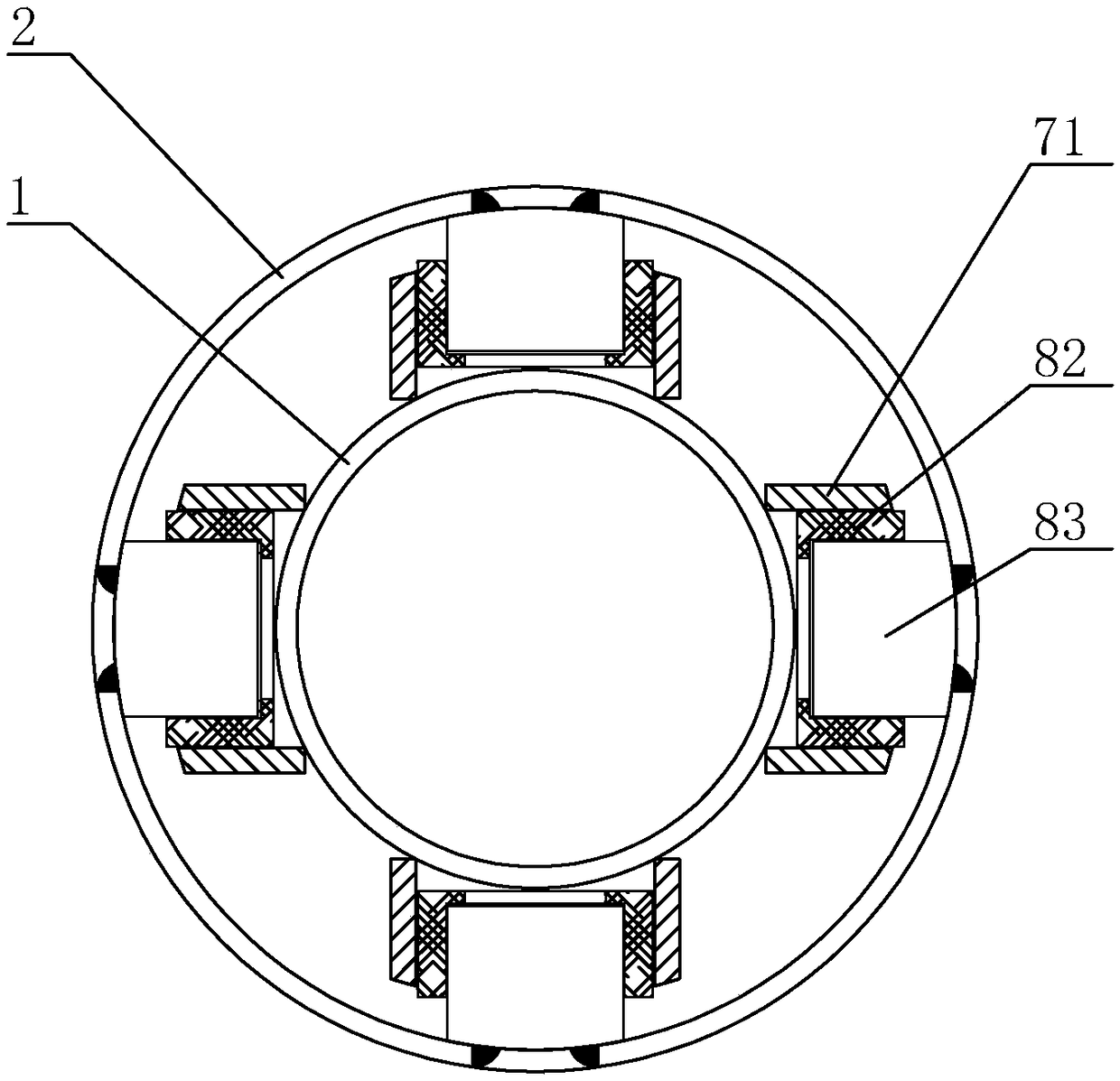

[0018] A continuous vacuum insulated double-walled pipe, comprising several sections of inner pipe 1 and several sections of outer pipe 2, the outer pipes 2 are sheathed on the outside of the inner pipe 1, and the two adjacent inner pipes 1 are welded, the A Huff tube 9 is welded between two adjacent outer tubes 2 , and several sets of heat-insulating sliding supports 7 and several sets of heat-insulating fixed supports 8 are arranged between the inner tube 1 and the outer tube 2 .

[0019] Such as figure 1 As shown, in the actual installation, the double-wall pipe includes 3 elbows and straight lines. At the same time, in order to ensure the smooth welding of the inner pipe 1, a certain space is reserved between two adjacent outer pipes 2. After the welding of the inner pipe 1 is completed , the two outer tubes 2 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com