Cosine fringe field projection module

A cosine and fringe technology, applied in the field of 3D measurement, can solve the problems of troublesome implementation, complicated control, and high production cost, and achieve the effect of simple structure and control, simple structure control, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

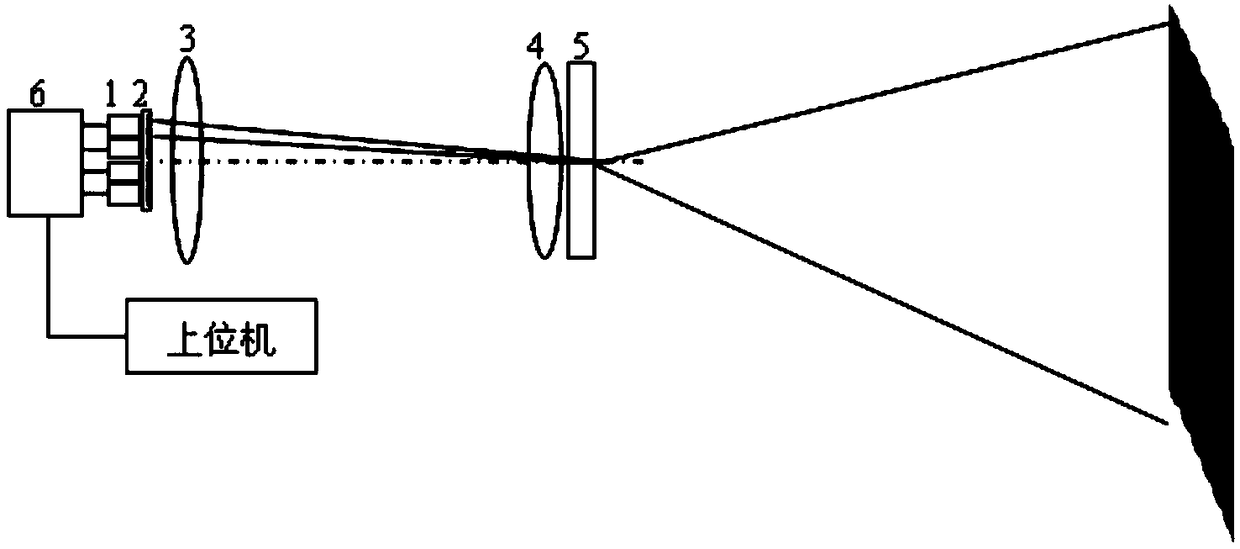

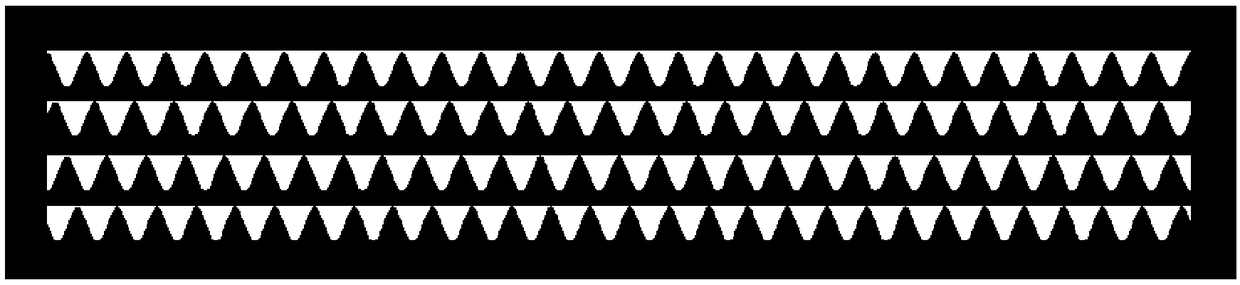

[0022] This embodiment provides a cosine fringe field projection module, its structure is as follows figure 1 As shown, it includes: a backlight source 1, a film 2, a field lens 3, a projection imaging lens 4, an expansion lens 5 and a channel control circuit 6; wherein, there are 4 binarized cosine patterns on the binarized cosine film, such as figure 2 As shown, each cosine pattern corresponds to a backlight, and optical isolation is made between each cosine pattern, so that when each backlight is turned on, only the corresponding cosine pattern can be irradiated; the four cosine patterns are shifted by 90° in sequence, correspondingly The four cosine fringe fields in the target area generated by the projection also meet the requirements of the four-step phase shift method; using the four-step time-sharing operation scheme, the external host computer selects the backlight to be turned on through the channel selection circuit, and the camera correspondingly shoots the cosine ...

Embodiment 2

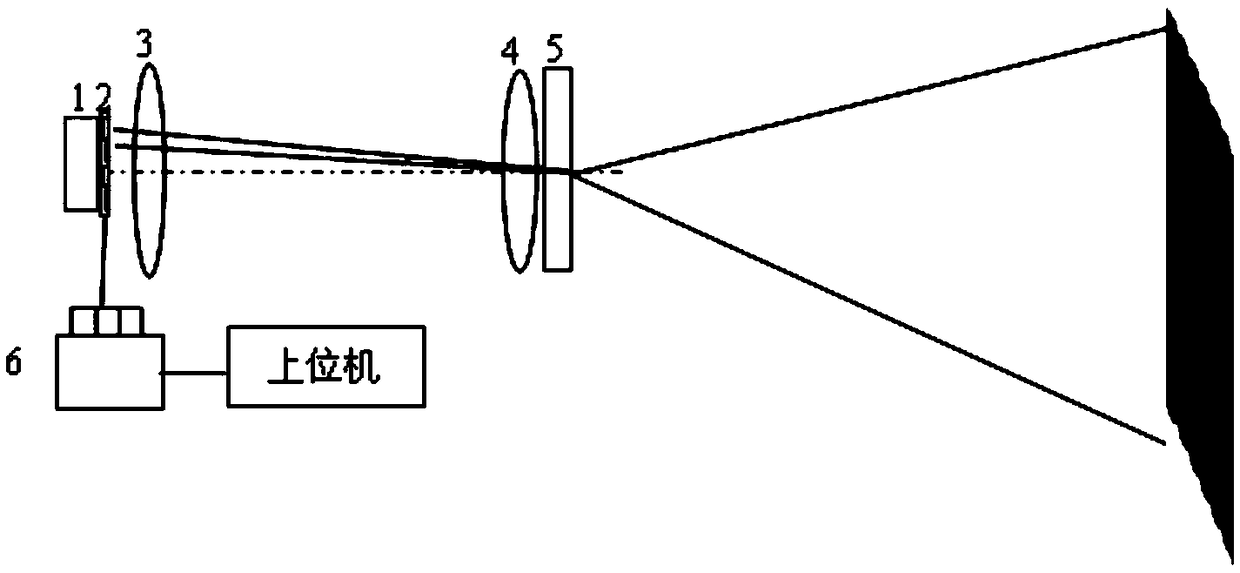

[0026] This embodiment provides a cosine fringe field projection module, its structure is as follows image 3 As shown, it comprises: backlight source 1, negative film (liquid crystal sheet) 2, field lens 3, projection imaging lens 4, expansion lens 5 and channel control circuit 6; its difference with embodiment 1 is: adopt liquid crystal sheet in the present embodiment As a negative, only one backlight source is needed; its working principle is the same as that of Embodiment 1.

[0027] The liquid crystal panel is a custom-made liquid crystal panel, and 4 binarized cosine patterns are obtained by making patterns of ITO electrodes. The liquid crystal panel has a common electrode and four control electrodes, and each control electrode corresponds to a cosine pattern, which is normally opaque. Pass through, after power on; there is only one backlight, which is shared by four cosine patterns. The binarized cosine pattern on the liquid crystal, such as Figure 4 As shown, consid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com