Sample sealing device and method for testing active and passive real-time acoustic waves in rock breaking process

A rock sample and rock technology, applied in the field of rock fracture testing, can solve the problems of difficult rock triaxial compressive strength, confining pressure, information difficult to collect in real time, difficult to obtain rock acoustic emission positioning information, etc., to achieve high The effect of laboratory instruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0039] The invention provides an active and passive real-time sound wave testing and sealing device and method in the rock destruction process.

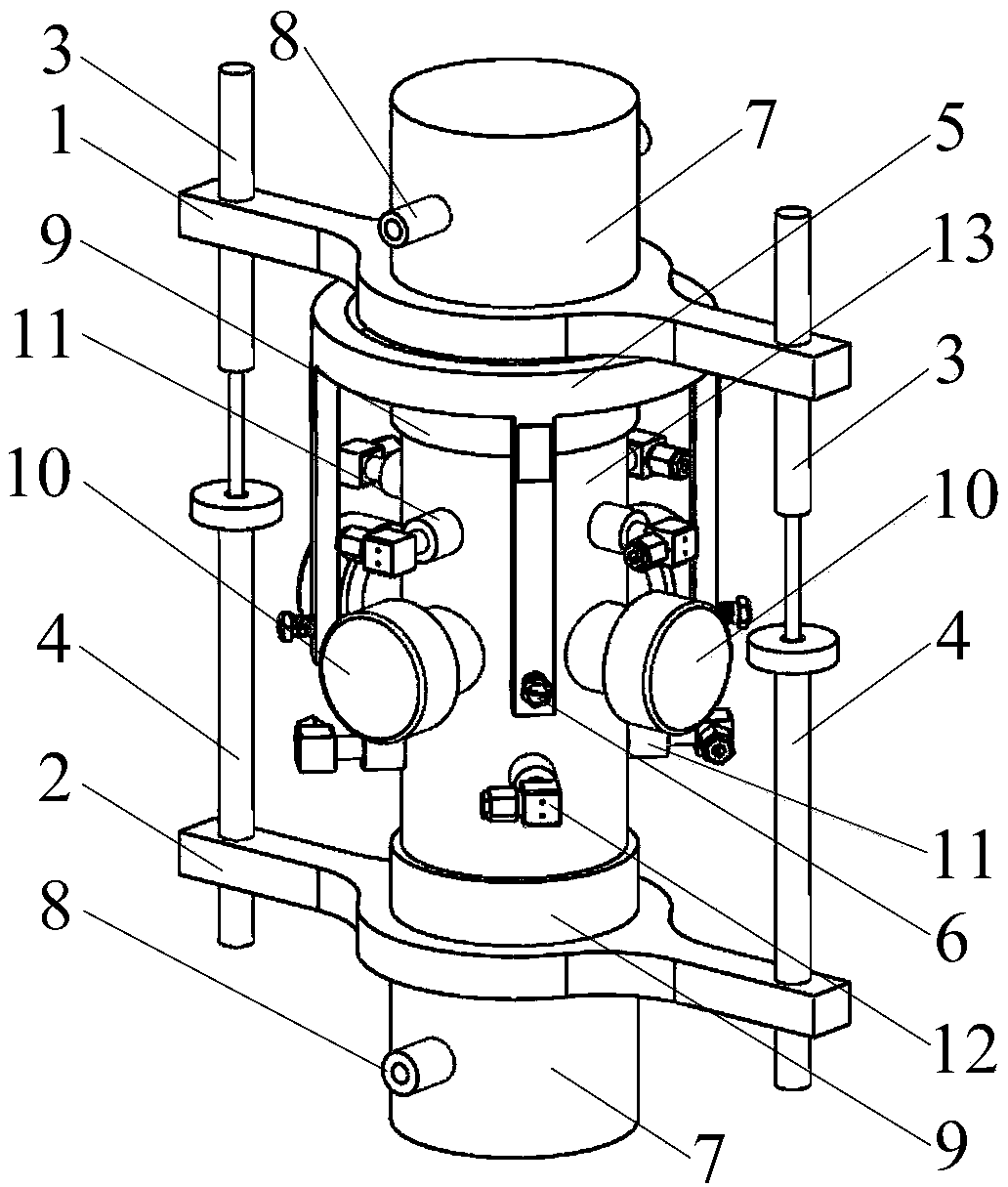

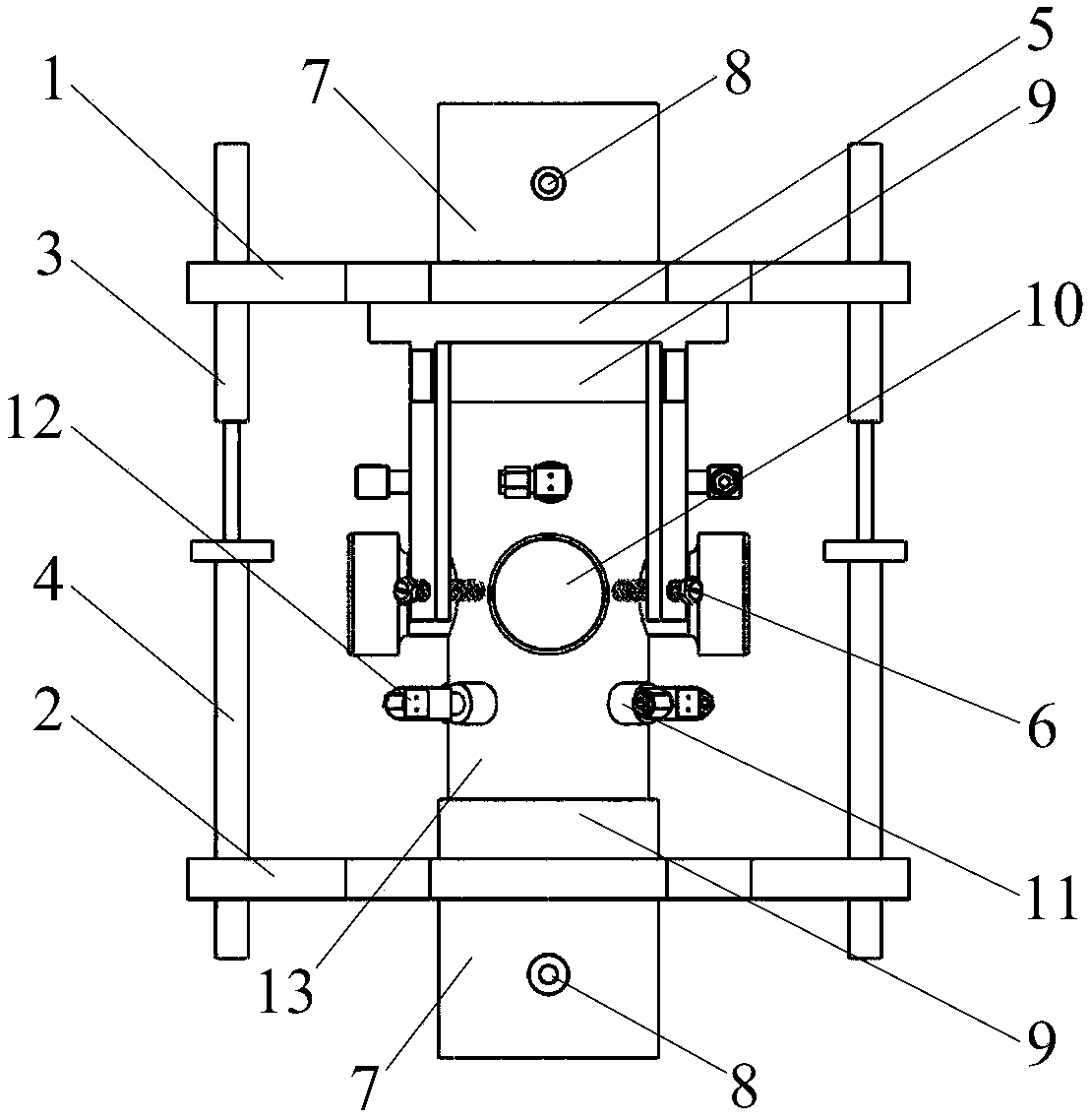

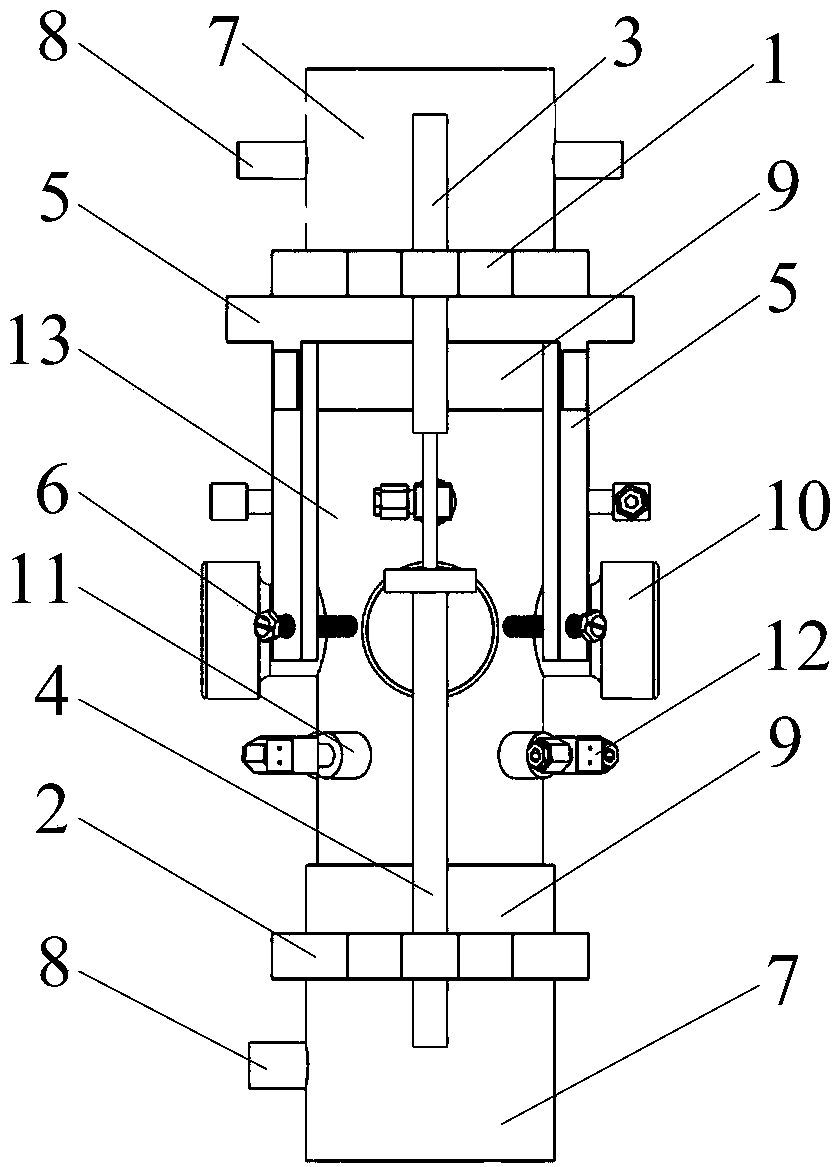

[0040] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the device includes a load application module, a displacement monitoring module, a load ultrasonic monitoring module and an acoustic emission monitoring and positioning module, and the rock sample 13 is placed in the center of the whole device;

[0041] The load application module includes a rigid block 7 and a three-axis electro-hydraulic servo testing machine. The axial pressure provided by the three-axis electro-hydraulic servo testing machine acts directly on the rigid block 7, and the confining pressure provided by the three-axis el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com