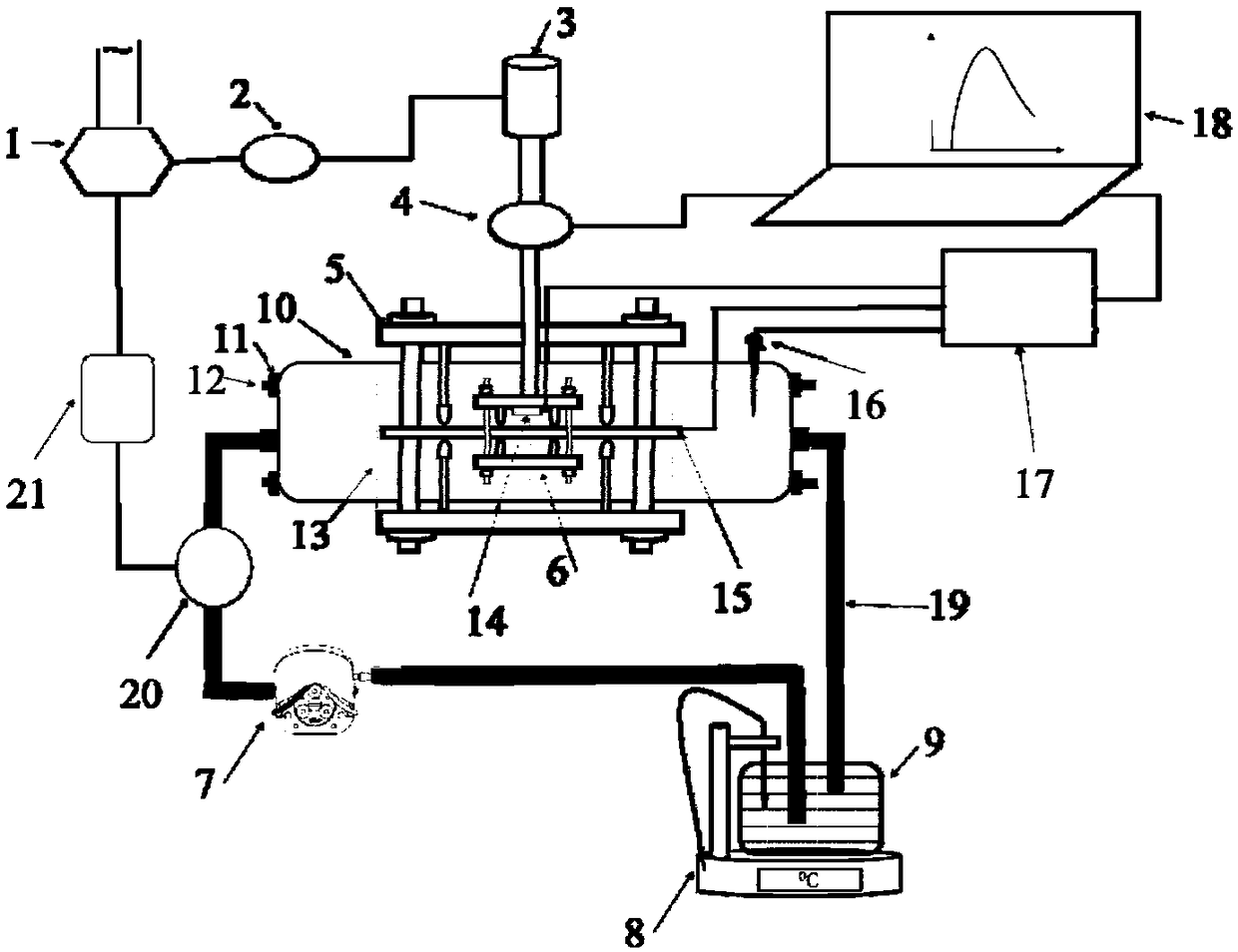

In-situ detection platform simulating multifield coupling environment

An in-situ detection and platform technology, used in measuring devices, using repetitive force/pulse force to test material strength, instruments, etc., can solve the problems of lack of material corrosion behavior research, inability to reflect load status, and high equipment requirements. The effect of simple operation, wide application range and universal applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

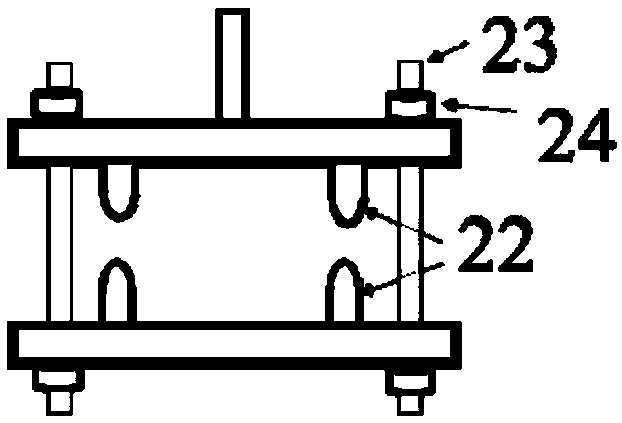

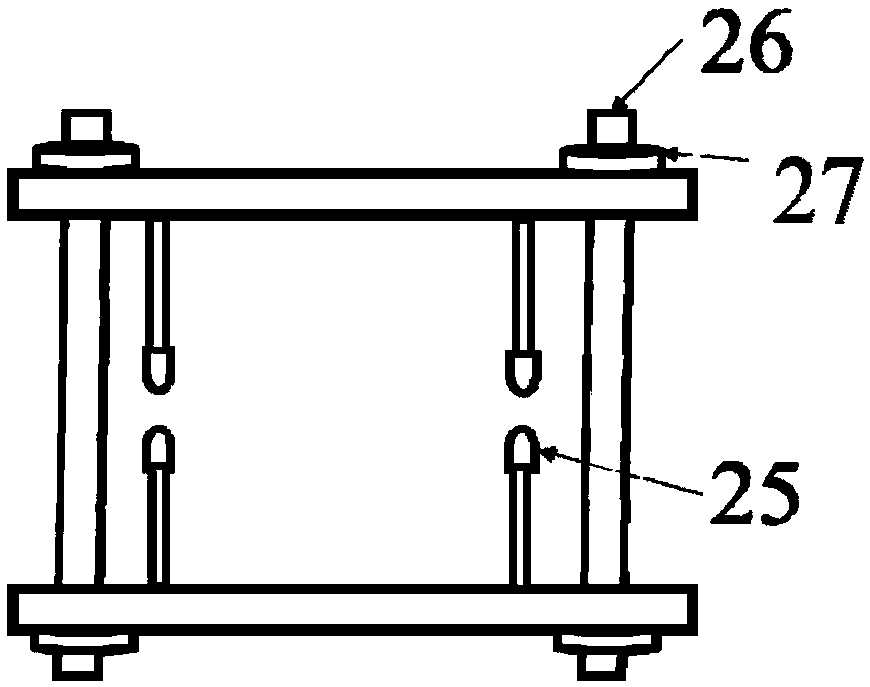

[0031] The selected AZ31B plate specimen 15 has a length of 120mm, a thickness of 2mm, and a width of 12mm. The time relay 2 is a double-cycle time relay; the variable voltage governor 1; the servo motor 3; the corrosive medium used is simulated body fluid, and the temperature is At 37°C, the speed of the flow field is controlled by the speed-adjustable peristaltic pump 7, the current control load is adjusted by the variable voltage governor 1, the load is measured by the stress sensor 4, and the frequency is adjusted by the time relay 2 to simulate the real human body corrosion environment Bending and corrosion fatigue experiments of magnesium alloy implanted devices at high and high temperatures, the indenters 22 and 25 of the loading composite fixture 6 and the supporting composite fixture 5 are polytetrafluoroethylene, and the impedance of the material is measured in real time through the electrochemical workstation 17 and the corrosion is calculated. speed.

Embodiment 2

[0033] The device used is the same as that in Example 1. The selected metal plate test piece 15 is 150mm, 2mm in thickness, and 40 steel in width of 15mm. The corrosion medium used is sodium chloride solution at a temperature of 25°C. The pump 7 controls the flow field speed, the variable voltage governor 1 is used to adjust the current to control the load, the stress sensor 4 is used to measure the load, and the time relay 2 adjusts the frequency to simulate the cyclic bending corrosion of the plate specimen in the 25°C marine environment In the fatigue test, the indenter 22 of the loading assembly 6 is stainless steel coated with polytetrafluoroethylene, and the indenter 25 of the supporting composite fixture 5 is polytetrafluoroethylene. The impedance of the material is measured in real time by the electrochemical workstation 17 and calculated Get the corrosion rate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com