A high-pressure liquid remover for removing debris

A high-pressure liquid and debris removal technology, which is applied in the field of high-pressure liquid debris remover, can solve the problems of power equipment, wires, etc., and achieve the effects of high efficiency of debris removal, simple operation, and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

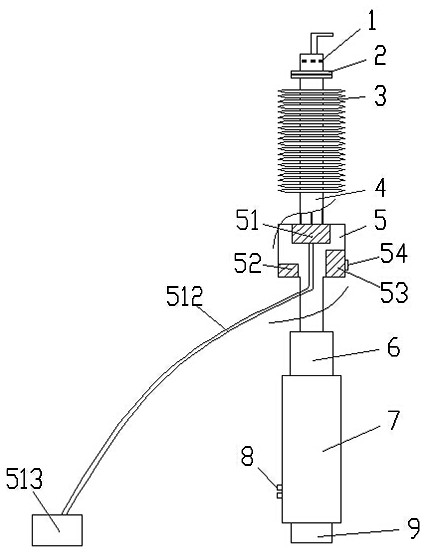

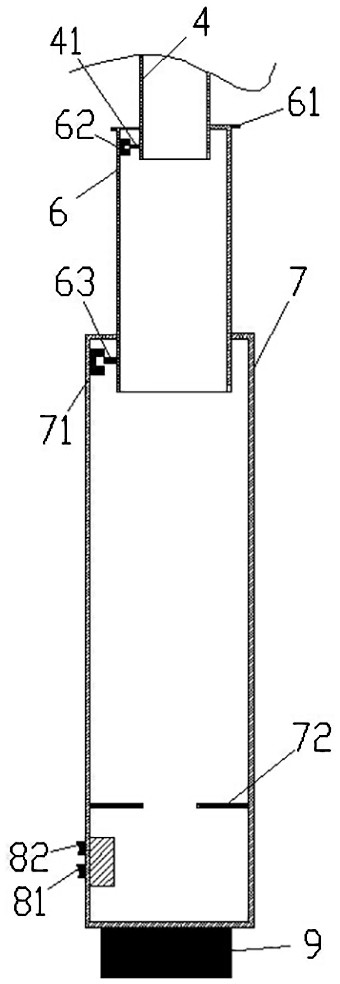

[0019] as attached Figures 1 to 2 As shown, a high-pressure liquid remover for removing debris includes a hand-held rod 7, an extension rod 6, and a working rod 4. The upper end of the working rod 4 is provided with a lighting lamp 1, and a cutting device 2 is provided below the lighting lamp 1. The middle part of the working rod 4 is provided with an insulator 3, and the working chamber 5 is arranged below the insulator 3, and a controller 52, a power pack 53 and a power unit 51 are arranged in the said studio 5, and the controller 52 is connected to the power pack 53, The power device 51 and the lighting lamp 1, the power device 51 is connected to the cutting device 2, the inside of the extension rod 6 is hollow, one end of the extension rod 6 is provided with a semicircular block I41, and the other end of the extension rod 6 is provided with a semicircular chute inside Ⅱ62, a blocking block 61 is provided on the outside, a control switch 8 is provided at the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com