Mineral safe dust removal equipment

A kind of dust removal equipment and safe technology, applied in the direction of using liquid separation agent, dispersed particle filtration, combined device, etc., can solve the problems of poor dust removal effect of dust removal equipment, water can not be recycled and protected performance, etc., to accelerate movement, save resources, enhance effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

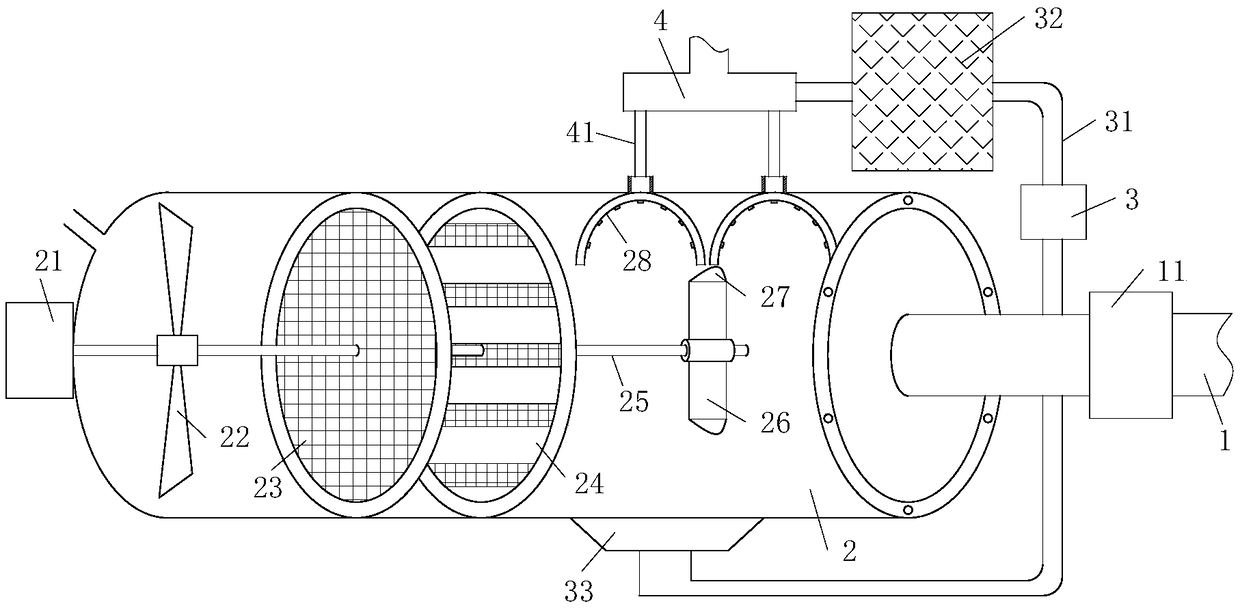

[0016] use Figure 1-Figure 2 A mining safety dust removal equipment according to an embodiment of the present invention is described as follows.

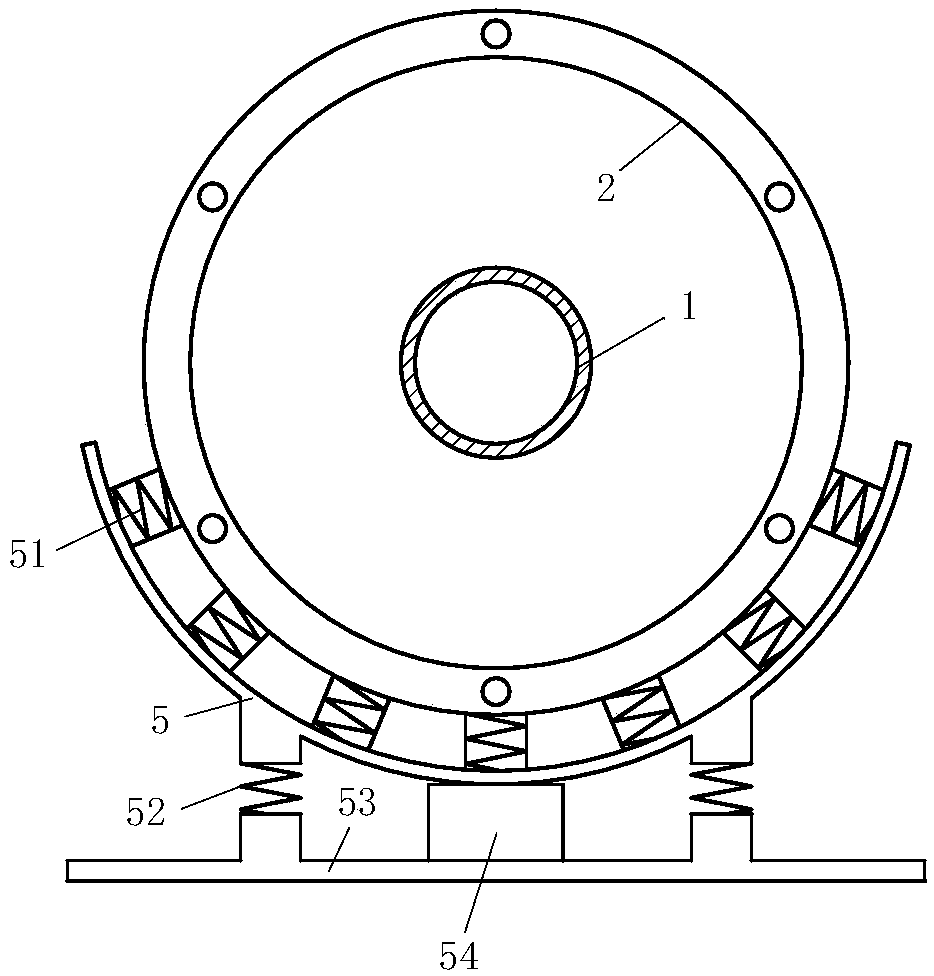

[0017] like Figure 1-Figure 2 As shown, a mine safety dedusting equipment according to the present invention comprises a dust removal box 2, one end of the dust removal box 2 is connected with a dust guide pipe 1, and the dust guide pipe 1 is provided with; the inside of the dust removal box 2 From right to left, two showers 28, an interceptor 24 and a filter screen 23 are arranged in turn. The top of the shower 28 communicates with the water inlet pipe 4 through the connecting pipe 41, and the water inlet pipe 4 is used to deliver the water for spraying. Water; the other end of the dust removal box 2 is provided with a motor 21, and the motor 21 is sequentially connected with the fan 22 and the impeller blade 26 through the rotating shaft 25. The fan 22 is located at the rightmost end of the dust removal box 2, and the outside o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com