Long-acting slow-release polycarboxylic acid slump retaining agent and preparation method thereof

A slow-release polycarboxylic acid and slump-retaining agent technology, applied in the field of building materials, can solve the problems of long transportation time of concrete mixer trucks, unable to fully meet market demand, insufficient slump-preserving performance, etc., and achieve good effect and slump-preserving performance. The effect of improving and good adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

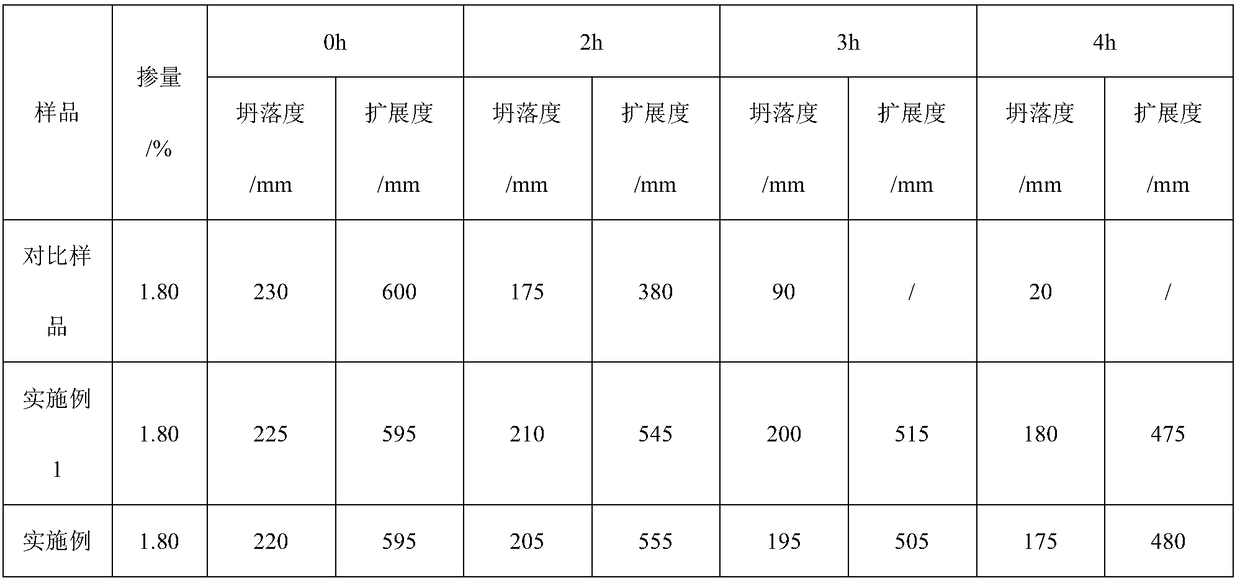

Examples

Embodiment 1

[0038] (1) Preparation of unsaturated esterified small monomers:

[0039] Under normal pressure, 41 parts of methacrylic acid, 71 parts of propionic acid, 130 parts of 3-bis(2-hydroxyethyl)amino-2-hydroxypropanesulfonic acid (DIPSO) were added to the reactor, and 0.25 1 part of copper chloride, 0.13 part of benzyltributylammonium chloride and 13 parts of chloroform, carry out esterification reaction, the esterification reaction temperature is 100 ℃, and the reaction time is 3 hours, after the reaction is finished, it is down to room temperature, that is to say, Saturated esterified small monomers.

[0040] (2) Copolymerization reaction:

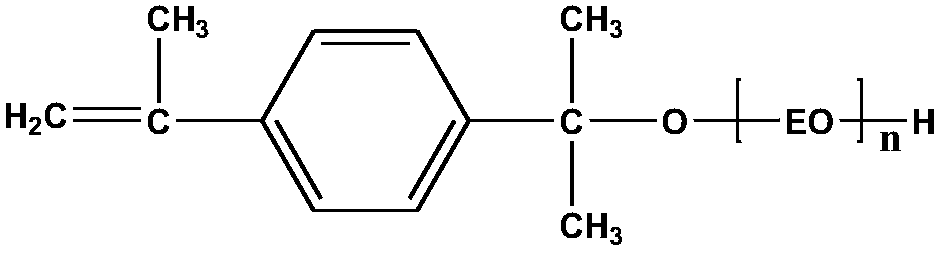

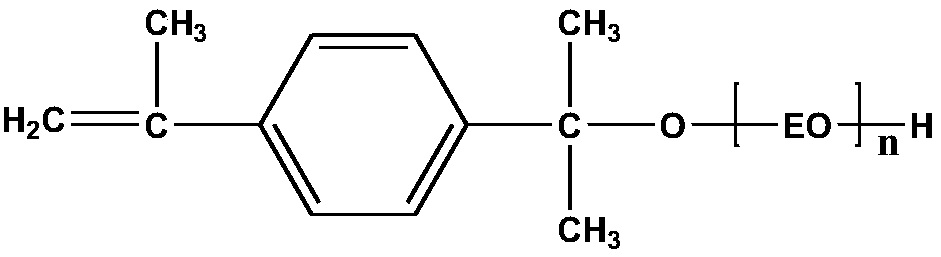

[0041] At room temperature, 100 parts of cumenyl polyoxyethylene ether P-1, 1 part of ethyl 3-butenyl phosphocarboxylate and 0.5 part of azodiimidazolinyl propane dihydrochloride were dissolved in an appropriate amount of deionized water as For the primer, adjust the pH of the primer to 5-6 with 1 part of acrylic acid.

[0042] Dissolve 3 ...

Embodiment 2

[0047] (1) Preparation of unsaturated esterified small monomers:

[0048] Under normal pressure, 60 parts of methacrylic acid, 162 parts of butyric acid, 130 parts of 3-bis(2-hydroxyethyl)amino-2-hydroxypropanesulfonic acid (DIPSO) were added to the reactor, and 0.55 Part of zinc chloride, 0.45 part of three (N-nitroso-N-phenylhydroxylamine) aluminum and 18 parts of carbon tetrachloride, carry out esterification reaction, the esterification reaction temperature is 110 ℃, and the reaction time is 4 hours, After the reaction is completed, the temperature is lowered to room temperature, and the unsaturated esterified small monomer is obtained.

[0049] (2) Copolymerization reaction:

[0050] At room temperature, 100 parts of cumenyl polyoxyethylene ether P-2, 2 parts of ethyl 3-butenyl phosphocarboxylate and 1.5 parts of azodiimidazolinyl propane dihydrochloride were dissolved in an appropriate amount of deionized water as For the primer, use 2 parts of acrylic acid to adjust the...

Embodiment 3

[0056] (1) Preparation of unsaturated esterified small monomers:

[0057] Under normal pressure, 90 parts of methacrylic acid, 85 parts of butyric acid, 130 parts of 3-bis(2-hydroxyethyl)amino-2-hydroxypropanesulfonic acid (DIPSO) were added to the reactor, and 0.6 1 part of copper chloride, 0.35 part of benzyltributylammonium chloride and 40 parts of chloroform, carry out esterification reaction, the esterification reaction temperature is 120 ℃, and the reaction time is 5 hours, and after the reaction is finished, it is down to room temperature, that is, no Saturated esterified small monomers.

[0058] (2) Copolymerization reaction:

[0059] At room temperature, 100 parts of cumenyl polyoxyethylene ether P-3, 3 parts of ethyl 3-butenyl phosphocarboxylate and 1 part of azodiimidazolinyl propane dihydrochloride were dissolved in an appropriate amount of deionized water as For the primer, adjust the pH of the primer to 5-6 with 3 parts of methacrylic acid.

[0060] Dissolve 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com