MS-GPPS composite optical diffusing plate and preparation method

An MS-GPPS, optical diffusion technology, applied in the field of MS-GPPS composite optical diffusion sheet and its preparation, can solve the problems of poor PMMA molding flow performance, general light diffusion effect, general frosting effect, etc., to achieve long service life, saving Packaging and transportation costs, the effect of saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

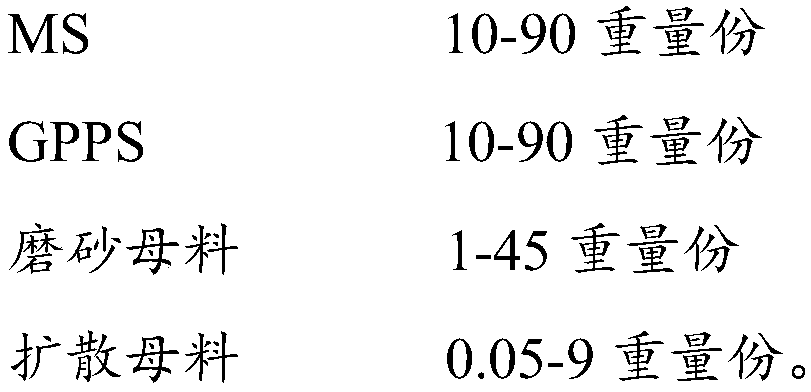

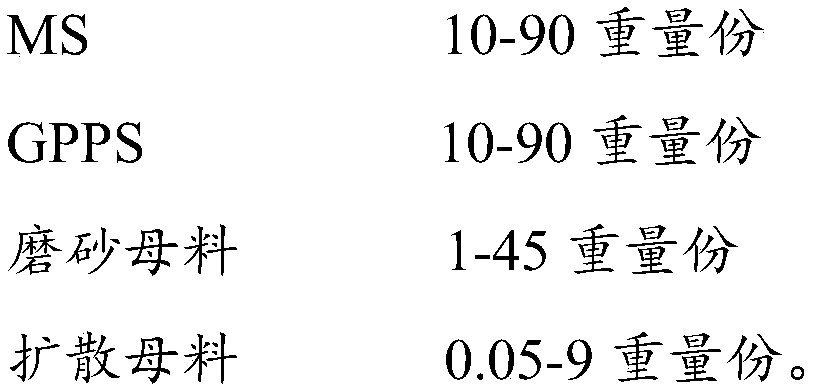

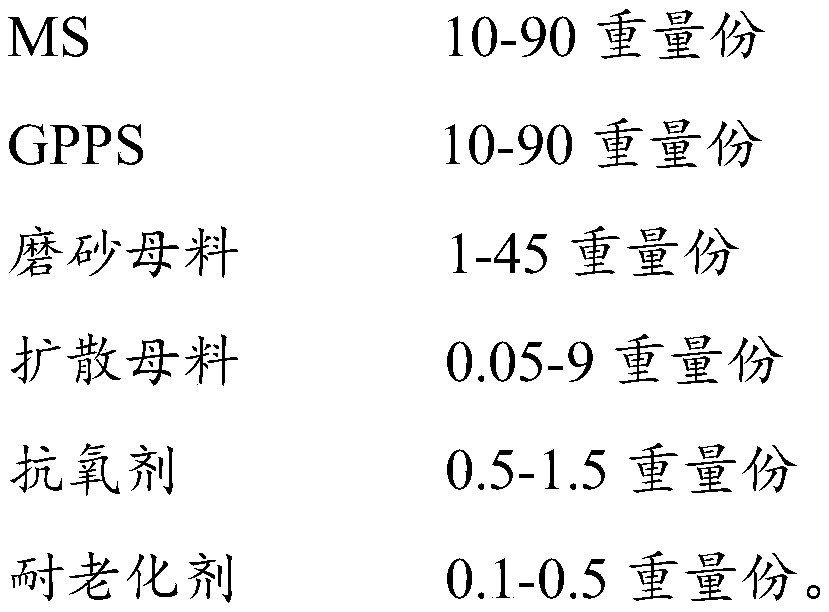

Method used

Image

Examples

preparation example Construction

[0044] The present invention also provides the preparation method of above-mentioned a kind of MS-GPPS composite optical diffusion plate, comprises the steps:

[0045] (1) Automatically mix MS, frosted masterbatch, antioxidant and anti-aging agent according to the set ratio through the compounder to obtain compound A;

[0046] (2) GPPS, diffusion masterbatch, antioxidant and anti-aging agent are automatically mixed uniformly according to the set ratio by the compounding device, and compounded material B is obtained;

[0047] (3) Melting and extruding the compounding material A through an extrusion device to form a layer A material;

[0048] (4) Melting and extruding the compound B through an extrusion device to form a layer B material;

[0049] (5) The A-layer material and the B-layer material are distributed and stacked through a distributor, and then calendered by rolling equipment to obtain a MS-GPPS composite optical diffusion plate

[0050] Among them, the A-layer mater...

Embodiment 1

[0056] After the MS of 20 parts by weight, the matte masterbatch of 2 parts by weight, the antioxidant of 0.5 parts by weight and the aging resistance agent of 0.2 parts by weight are automatically mixed uniformly by a compounding device, compound A is obtained.

[0057] After the GPPS of 80 parts by weight, the diffusion masterbatch of 2 parts by weight, the antioxidant of 0.5 parts by weight and the aging resistance agent of 0.2 parts by weight are automatically mixed by a compounder, compound B is obtained.

[0058] The compound A is melted and extruded through an extrusion device to form a layer A material.

[0059] The compound B is melt-extruded through an extrusion device to form a B-layer material.

[0060] The A-layer material and the B-layer material are distributed and stacked into an ABA structure through a distributor, calendered and compounded by a three-roll calender, cooled and solidified to obtain a MS-GPPS composite optical diffusion plate.

[0061] After te...

Embodiment 2

[0063] After the MS of 80 parts by weight, the matte masterbatch of 2 parts by weight, the antioxidant of 0.5 parts by weight and the antiaging agent of 0.2 parts by weight are automatically mixed uniformly by a compounding device, compound A is obtained.

[0064] After the GPPS of 20 weight parts, the diffusion masterbatch of 2 weight parts, the antioxidant of 0.5 weight part and the aging resistance agent of 0.2 weight part are mixed homogeneously by compounding machine automatically, get compounding material B.

[0065] The compound A is melted and extruded through an extrusion device to form a layer A material.

[0066] The compound B is melt-extruded through an extrusion device to form a B-layer material.

[0067] The A-layer material and the B-layer material are distributed and stacked into an ABA structure through a distributor, calendered and compounded by a three-roll calender, cooled and solidified to obtain a MS-GPPS composite optical diffusion plate.

[0068] Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com