A kind of petg-as composite optical diffusion plate and its preparation method

A PETG-AS, optical diffusion technology, applied in the field of PETG-AS composite optical diffusion sheet and its preparation, can solve the problems of general frosting effect, cumbersome process, bad and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

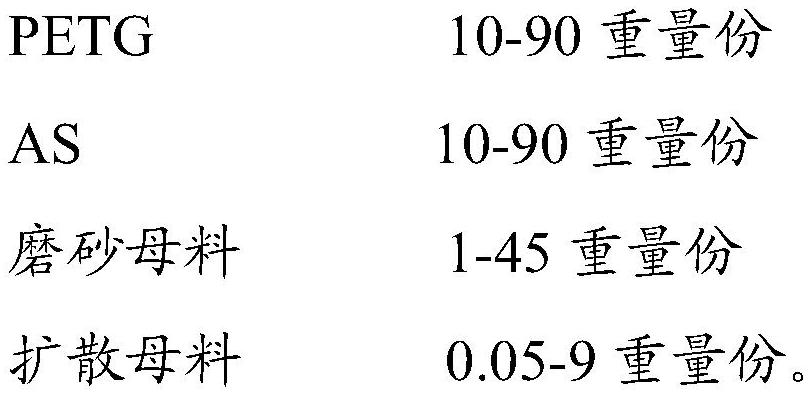

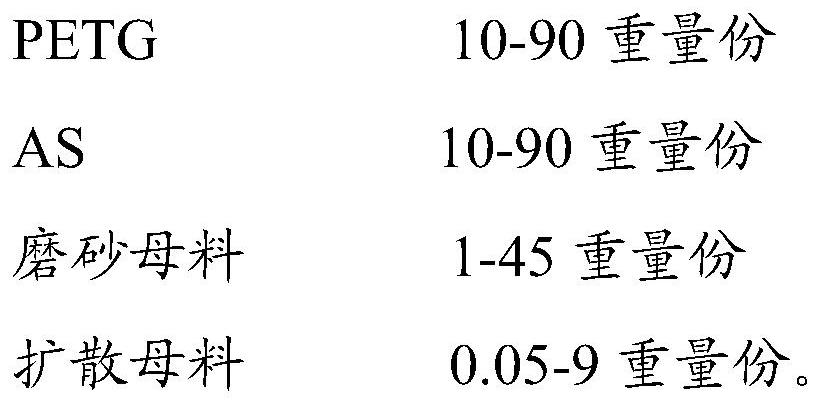

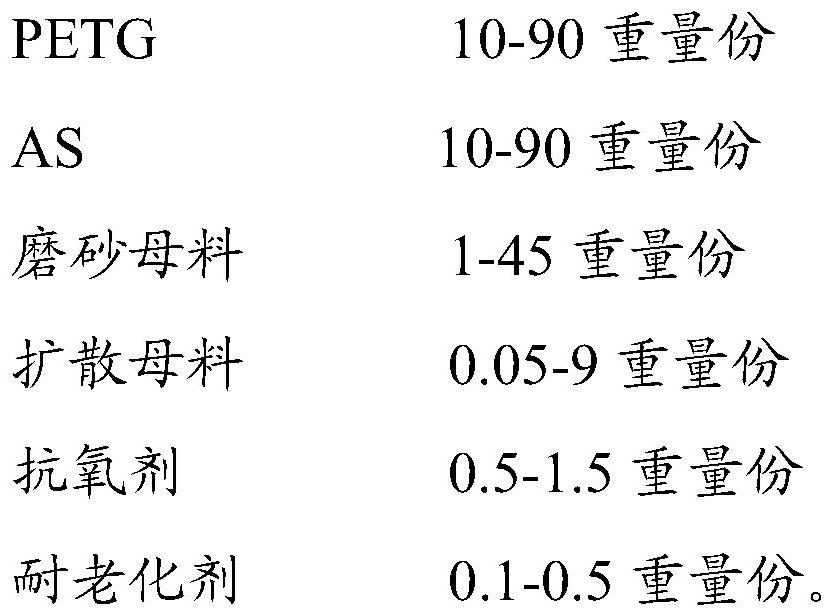

[0042] The present invention also provides a method for preparing the above-mentioned PETG-AS composite optical diffusion plate, comprising the following steps:

[0043](1) Automatically mix PETG, frosted masterbatch, antioxidant and anti-aging agent according to the set ratio through the compounder to obtain compound A;

[0044] (2) Automatically mix AS, diffusion masterbatch, antioxidant and anti-aging agent through the compounder according to the set ratio to obtain compound B;

[0045] (3) Melting and extruding the compounding material A through an extrusion device to form a layer A material;

[0046] (4) Melting and extruding the compound B through an extrusion device to form a layer B material;

[0047] (5) The A-layer material and the B-layer material are distributed and stacked by a distributor, and then calendered by rolling equipment to obtain a PETG-AS composite optical diffusion sheet.

[0048] Among them, the A-layer material and the B-layer material are distrib...

Embodiment 1

[0054] Compound A was obtained by automatically mixing 90 parts by weight of PETG, 2 parts by weight of frosting masterbatch, 0.5 parts by weight of antioxidant and 0.2 parts by weight of anti-aging agent through a compounding machine.

[0055] Compound B was obtained by automatically mixing 90 parts by weight of AS, 2 parts by weight of diffusion masterbatch, 0.5 parts by weight of antioxidant and 0.2 parts by weight of anti-aging agent through a compounding machine.

[0056] The compound A is melted and extruded through an extrusion device to form a layer A material.

[0057] The compound B is melt-extruded through an extrusion device to form a B-layer material.

[0058] The A-layer material and the B-layer material are distributed and laminated by a distributor to form an ABA structure, calendered and compounded by a three-roll calender, cooled and solidified to obtain the PETG-AS composite optical diffusion plate.

[0059] After testing, the PETG-AS composite optical diff...

Embodiment 2

[0061] Compound A was obtained by automatically mixing 10 parts by weight of PETG, 2 parts by weight of frosted masterbatch, 0.5 parts by weight of antioxidant and 0.2 parts by weight of anti-aging agent through a compounding machine.

[0062] Compound B was obtained by automatically mixing 90 parts by weight of AS, 2 parts by weight of diffusion masterbatch, 0.5 parts by weight of antioxidant and 0.2 parts by weight of anti-aging agent through a compounding machine.

[0063] The compound A is melted and extruded through an extrusion device to form a layer A material.

[0064] The compound B is melt-extruded through an extrusion device to form a B-layer material.

[0065] The A-layer material and the B-layer material are distributed and laminated by a distributor to form an ABA structure, calendered and compounded by a three-roll calender, cooled and solidified to obtain the PETG-AS composite optical diffusion plate.

[0066] After testing, the PETG-AS composite optical diffu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com