Annular component carburizing and quenching technology

A technology of carburizing and quenching, parts, applied in the field of heat treatment, can solve the problems of increasing production cost, uneven carburizing of workpiece surface, poor carburizing effect, etc., achieve full carburizing, speed up carburizing rate, and improve carburizing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

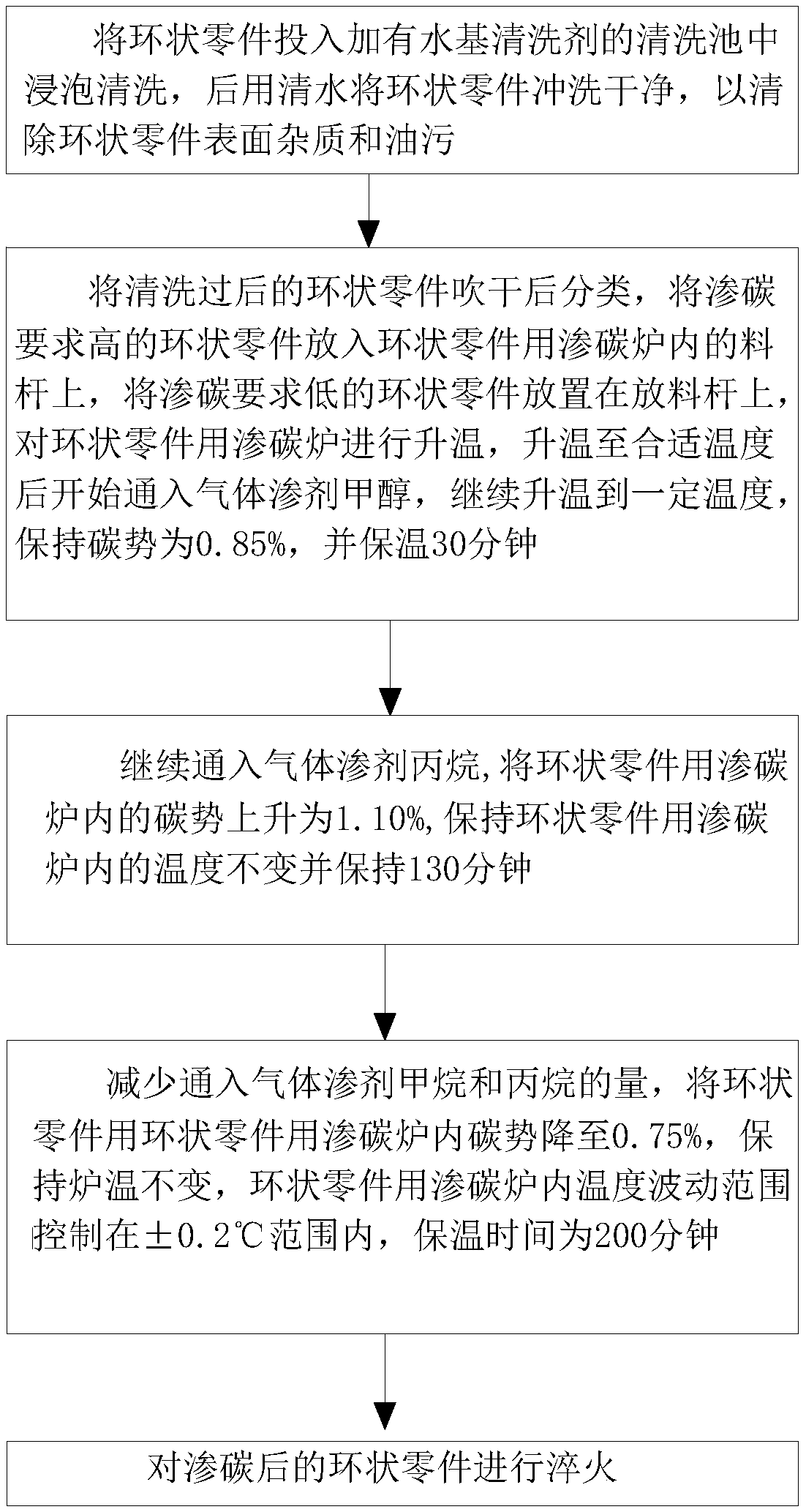

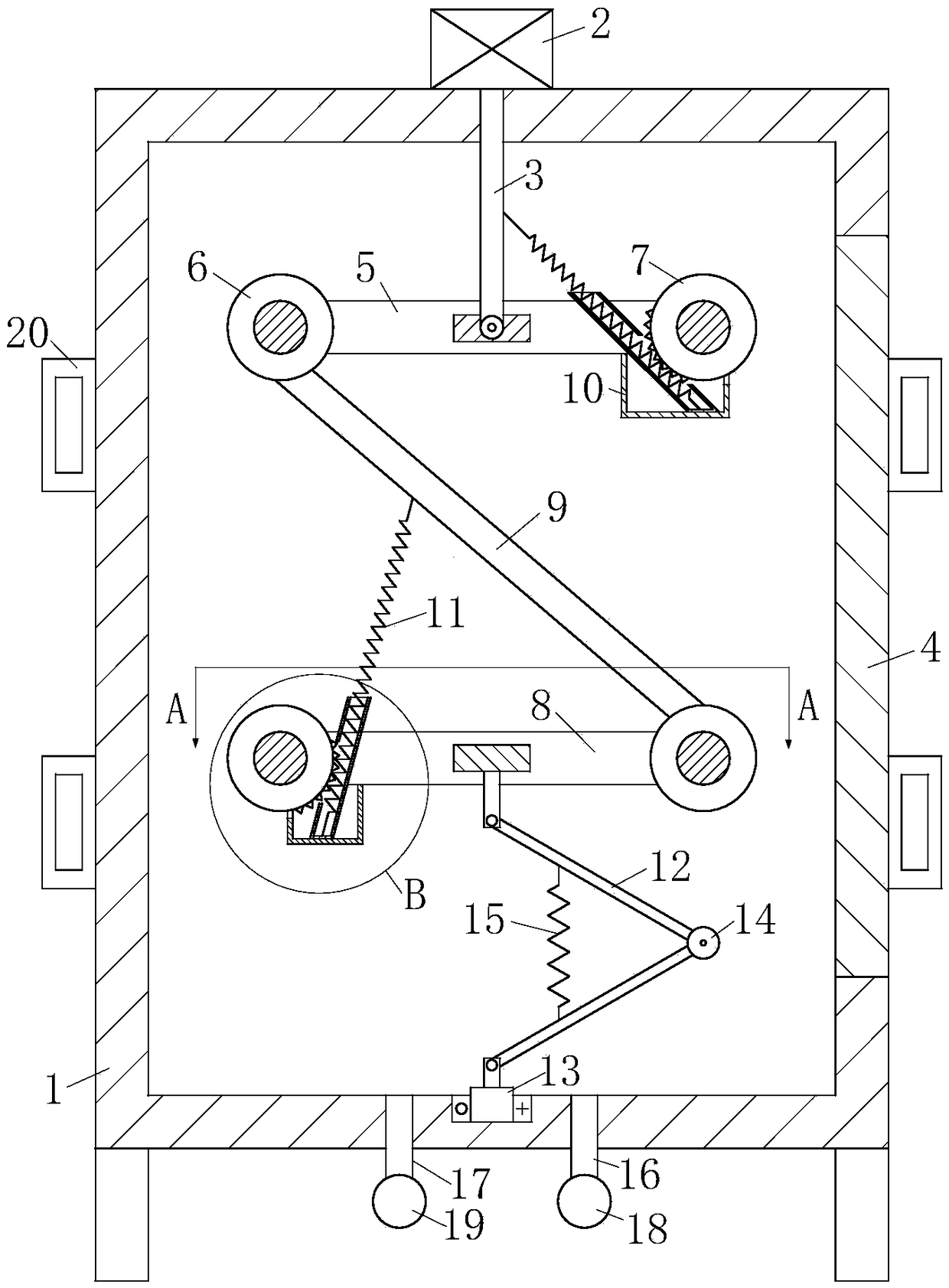

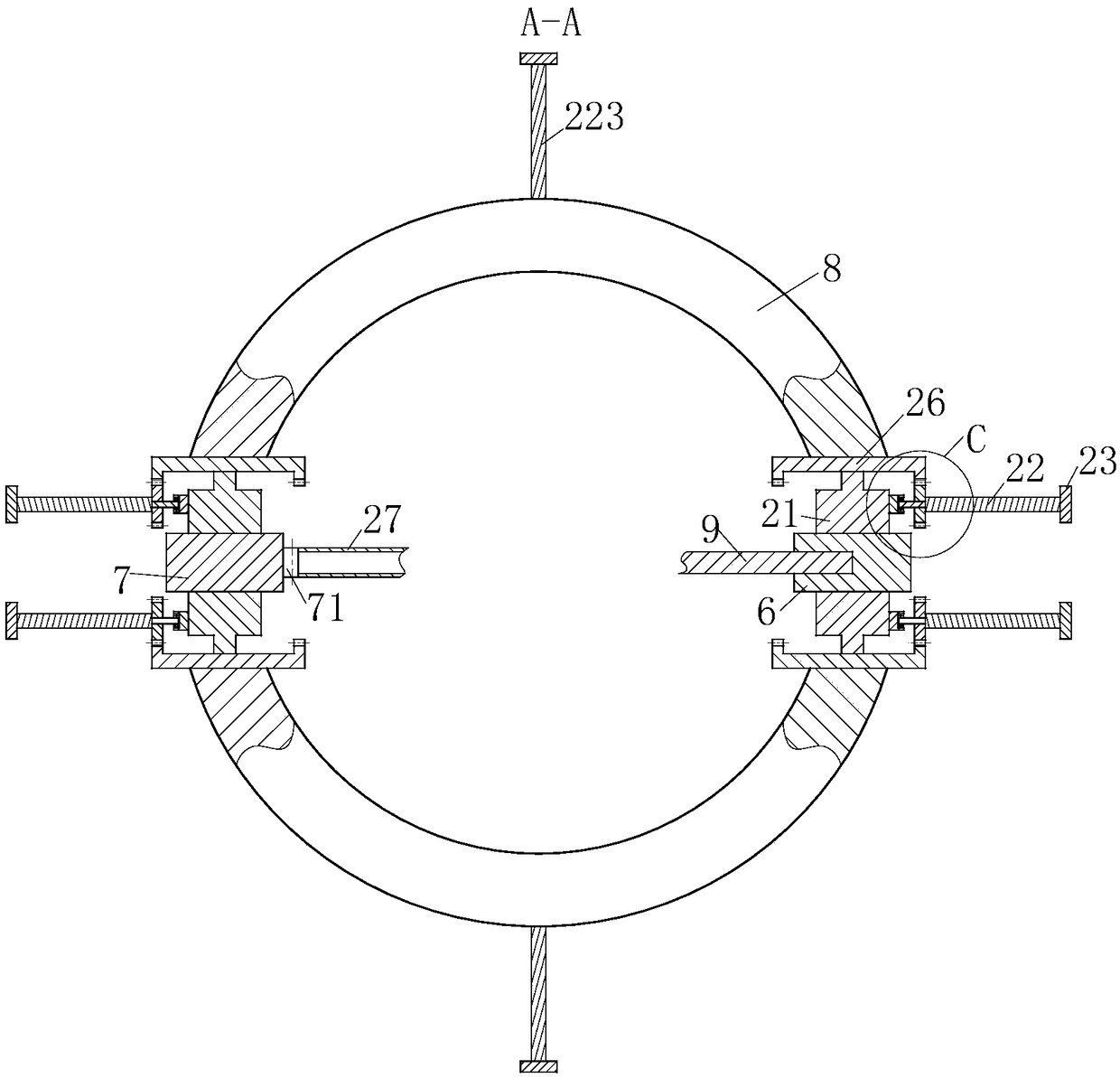

[0030] use Figure 1-7 A carburizing and quenching process for an annular part of the present invention is described as follows.

[0031] Such as Figure 1-7 , a carburizing and quenching process for ring parts according to the present invention, the process comprises the following steps:

[0032] S1: Put the ring-shaped parts into the cleaning pool with water-based cleaning agent for soaking and cleaning, and then rinse the ring-shaped parts with clean water to remove impurities and oil stains on the surface of the ring-shaped parts, and clean the impurities and oil stains on the surface of the ring-shaped parts To ensure the carburizing accuracy of ring parts;

[0033] S2: Dry the ring-shaped parts cleaned in S1 and then sort them. Put the ring-shaped parts with high carburizing requirements on the material rod in the carburizing furnace for ring parts, and place the ring-shaped parts with low carburizing requirements. On the discharge rod, the space in the carburizing fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com