Automatic sewing work station for bullet-proof clothes

A technology for bulletproof vests and workstations, which is applied in sewing equipment, sewing machine components, textiles and papermaking, etc. It can solve problems such as broken needles and hard bulletproof cores, and achieve the effect of reducing broken needles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Specific embodiments of the present invention will be further described in detail below.

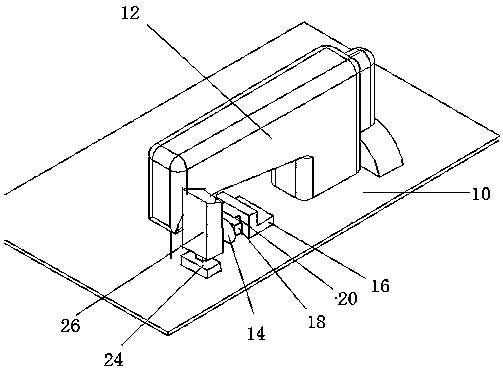

[0013] Such as figure 1 Shown, a kind of body armor automatic sewing workstation of the present invention is special for sewing body armor. The body armor includes multiple layers of fabrics and block-shaped bulletproof cores arranged in rows between the layers of fabrics. A kind of body armor automatic sewing workstation of the present invention comprises machine platform 10, is provided with a sewing machine 12, 2 guide wheels 14 that are rotatably arranged between adjacent two rows of bulletproof cores on the machine platform 10, by sewing machine 12 walking cloth teeth When the cloth of the bullet-proof clothing is driven to advance, the guide wheel 14 walks between the two rows of bullet-proof cores, and the sewing needle sews at a distance from the guide wheel 14 at the width of a bullet-proof core, so that the position can be well limited to avoid sewing Broken needle.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com