Double-sided composite aluminum sheet

A composite aluminum, double-sided technology, used in printed circuit parts, printed circuits, circuit substrate materials, etc., can solve problems such as affecting the quality of holes, scratching the green oil insulating layer, and having to stop to replace the drill needle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

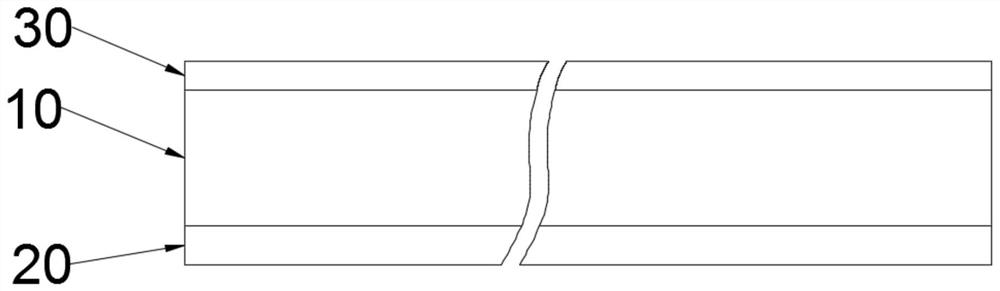

[0028] see figure 1 , the present invention provides a double-sided composite aluminum sheet, comprising: an aluminum sheet body 10, an anti-splash resin coating 20 and a precise alignment resin layer 30 respectively arranged on two sides of the aluminum sheet body 10; The thickness of the top resin coating 20 is 10 μm-60 μm, and the hardness is 4H-9H; the coating thickness of the precise alignment resin layer 30 is 40 μm-140 μm, and the hardness is 2B-H. In this embodiment, the thickness of the aluminum sheet body is 0.1 mm.

[0029] The anti-splash resin coating 20 is formed by drying the paint coated on the aluminum sheet body 10. The raw material composition of the paint is: resin 30wt%, crosslinking agent 10wt%, filler 25wt%, defoamer 0.1 wt%, leveling agent 0.1wt%, the balance is a solvent; the resin is epoxy resin E44; the crosslinking agent is methyl tetrahydrophthalic anhydride; the defoamer is BYK-A535; The agent is BYK-346, and the solvent is a solvent with a boil...

Embodiment 2

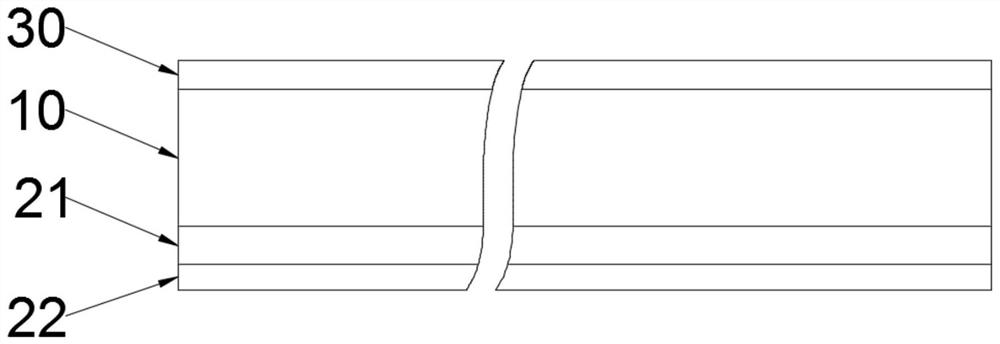

[0041] see figure 2 , the present invention provides a double-sided composite aluminum sheet, comprising: an aluminum sheet body 10, an anti-splash resin coating 20 and a precise alignment resin layer 30 respectively arranged on two sides of the aluminum sheet body 10; The thickness of the top resin coating 20 is 10 μm-60 μm, and the hardness is 4H-9H; the coating thickness of the precise alignment resin layer 30 is 40 μm-140 μm, and the hardness is 2B-H. In this embodiment, the thickness of the aluminum sheet body is 0.25mm.

[0042] The anti-splash resin coating 20 is composed of two layers of sub-coatings: an inner sub-coating 21, an outer sub-coating 22 coated on the inner sub-coating 21; an inner sub-coating 21 close to the aluminum sheet body 10 High hardness. That is, the hardness of the outer sub-coating 22 far away from the aluminum sheet body 10 is slightly smaller, and the outer sub-coating 22 can provide moderate flexibility to the inner sub-coating 21, so as to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com