Full-rotation automatic positioning processing equipment and method for simultaneous drilling and reaming of crankshaft flywheel

A technology for automatic positioning and processing equipment, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., to simplify operation methods, improve three-dimensional operation efficiency and equipment utilization, and ensure the same drilling and reaming processing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

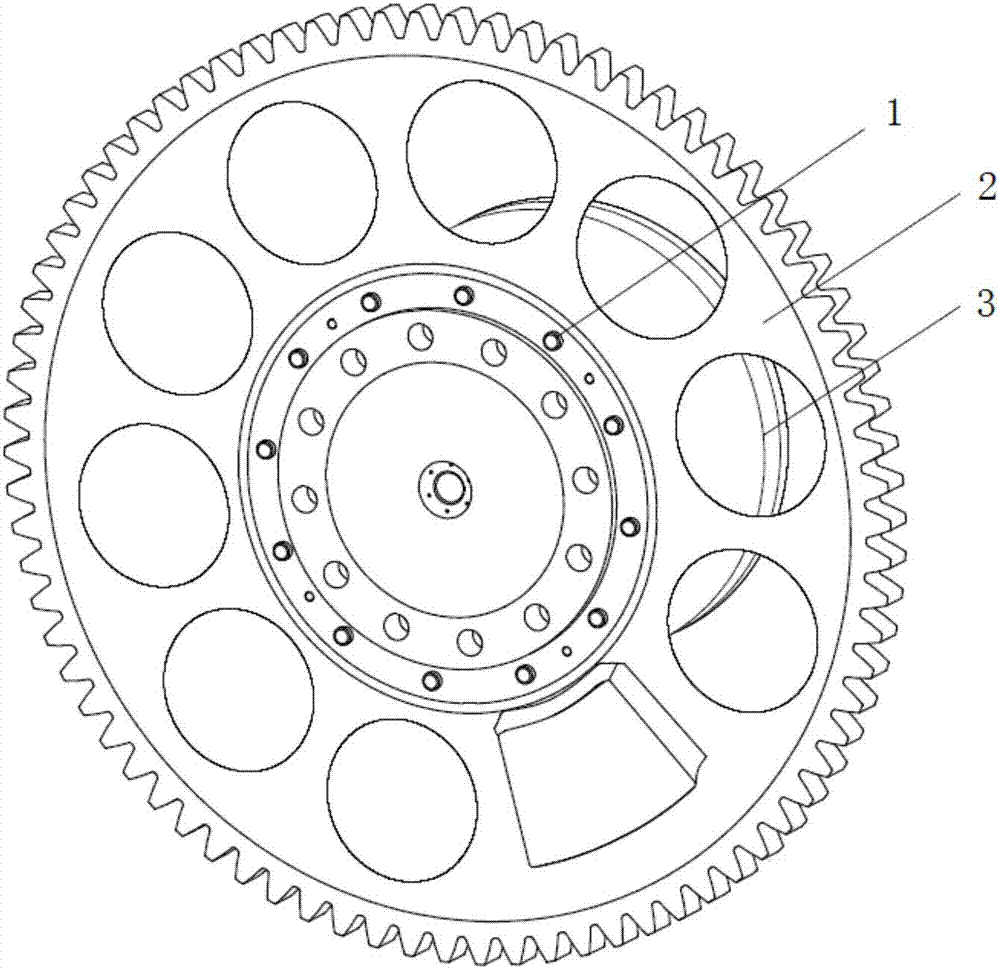

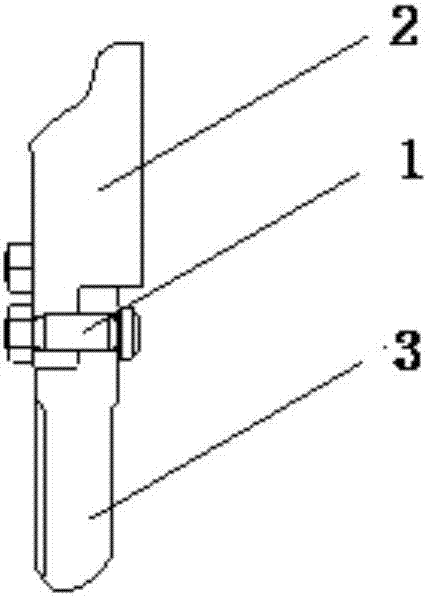

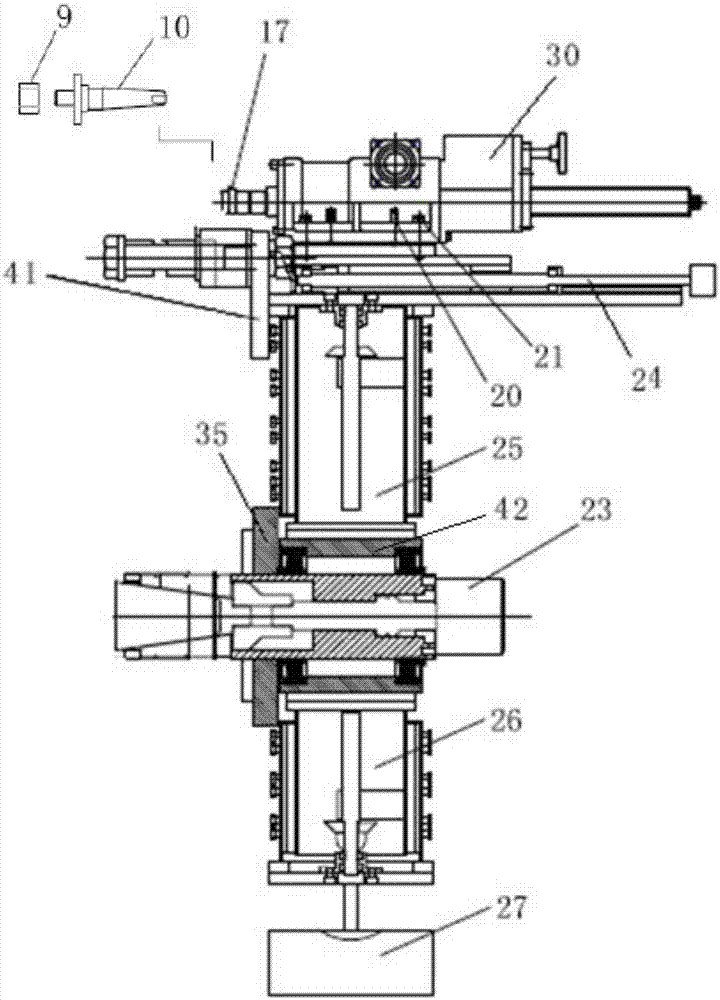

[0084] Aiming at the situation that the crankshaft of the marine low-speed diesel engine is supplied in the form of pre-drilled holes, the invention proposes a method for co-drilling and reaming the crankshaft and flywheel by using full-rotation automatic positioning processing equipment. see figure 1 and figure 2 , usually the crankshaft 3 is connected with the flywheel 2 equivalent hinge parts through tight fitting bolts 1 according to the different diesel engine models to form the crankshaft flywheel assembly. The size and position of the connecting holes need to be accurately guaranteed by co-drilling and reaming, and the present invention solves the processing problems of these co-drilling and reaming.

[0085] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention cannot be limited thereby.

[0086] It should be noted that, in the followin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com