Polycarbonate film applied to speaker network for electronic appliances and manufacturing method thereof

A polycarbonate and manufacturing method technology, applied in electrical components, sensors, sensor parts and other directions, can solve problems such as the production process affecting the surface quality of the speaker mesh, improve the appearance and surface quality, reduce the scrap rate, and reduce the impact resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

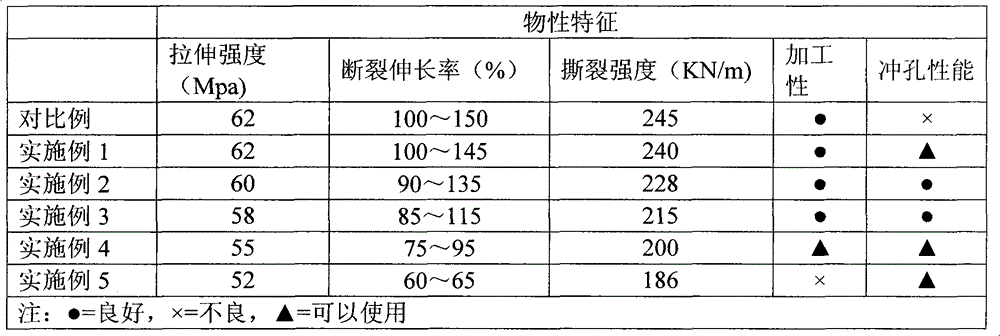

Examples

Embodiment 1

[0029] Embodiment 1: by weight percentage, the polycarbonate material of the present embodiment comprises following composition and content:

[0030] Powdered Polycarbonate 100

[0032] Dispersant 0.2

[0033] Heat stabilizer 0.25

[0034] Release agent 0.25

Embodiment 2

[0035] Embodiment 2: by weight percentage, the polycarbonate material of the present embodiment comprises following composition and content:

[0036] Powdered Polycarbonate 100

[0038] Dispersant 0.2

[0039] Heat stabilizer 0.25

[0040] Release agent 0.25

Embodiment 3

[0041] Embodiment 3: by weight percentage, the polycarbonate material of the present embodiment comprises following composition and content:

[0042] Powdered Polycarbonate 100

[0043] Talc powder 1

[0044] Dispersant 0.2

[0045] Heat stabilizer 0.25

[0046] Release agent 0.25

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com