Assembled shoes and manufacturing method thereof

A manufacturing method and shoe upper technology, applied in the direction of footwear, shoe soles, shoe-making machinery, etc., can solve problems such as high labor costs, affecting the connection between buttonholes and connecting buckles, and complicated manufacturing processes, so as to reduce the manufacturing process of shoe uppers , The fixing method is simple and firm, and the manufacturing process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

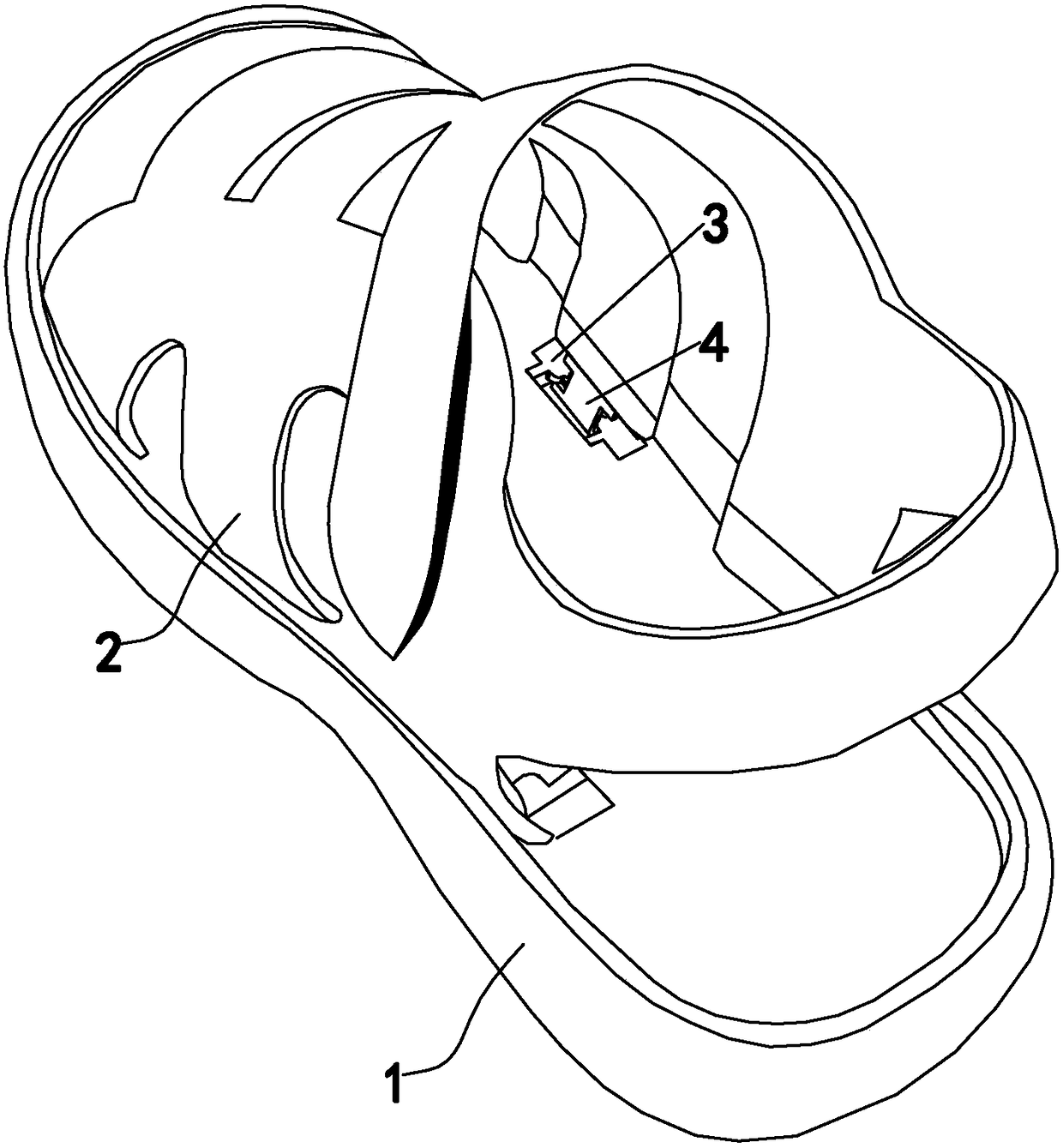

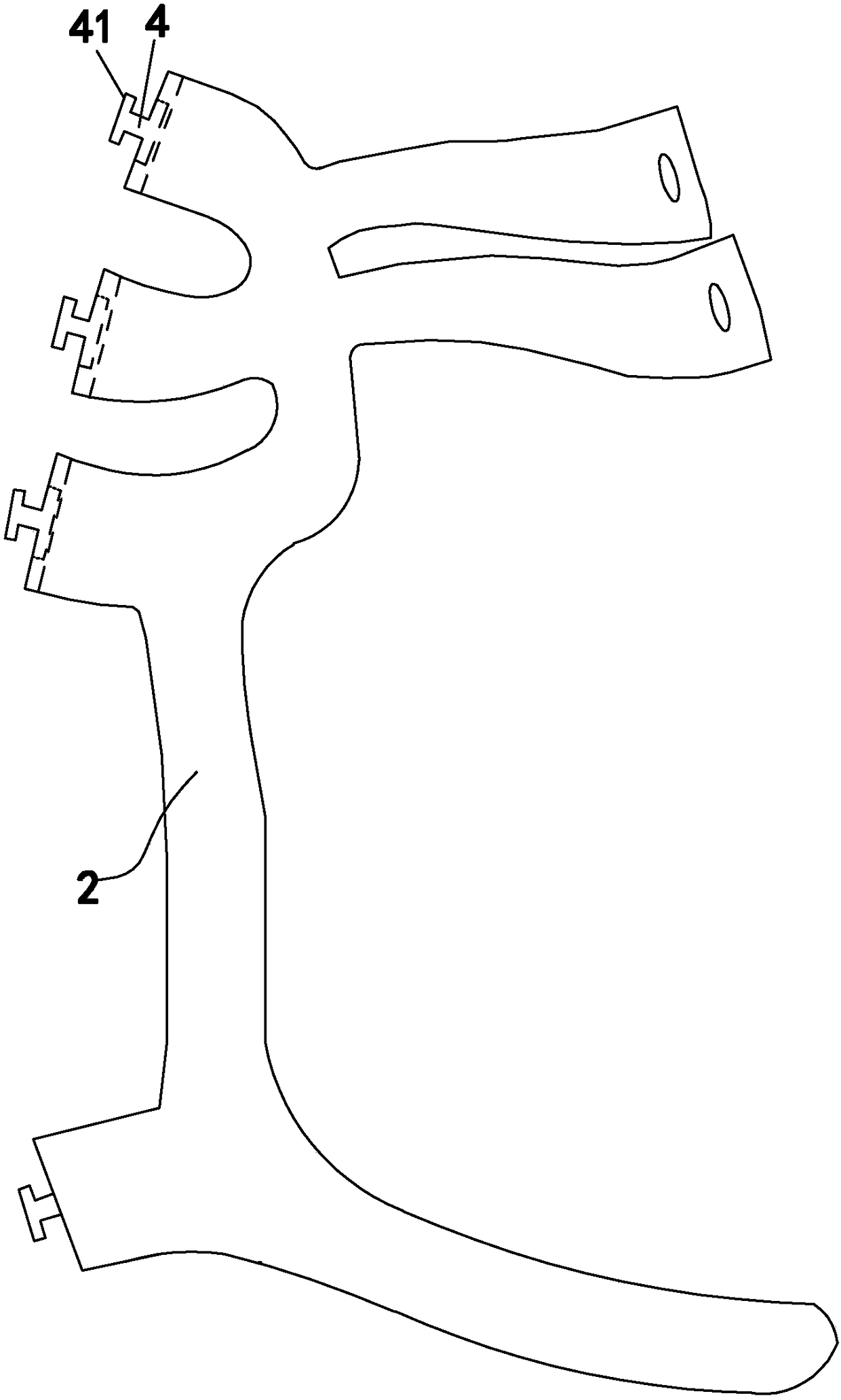

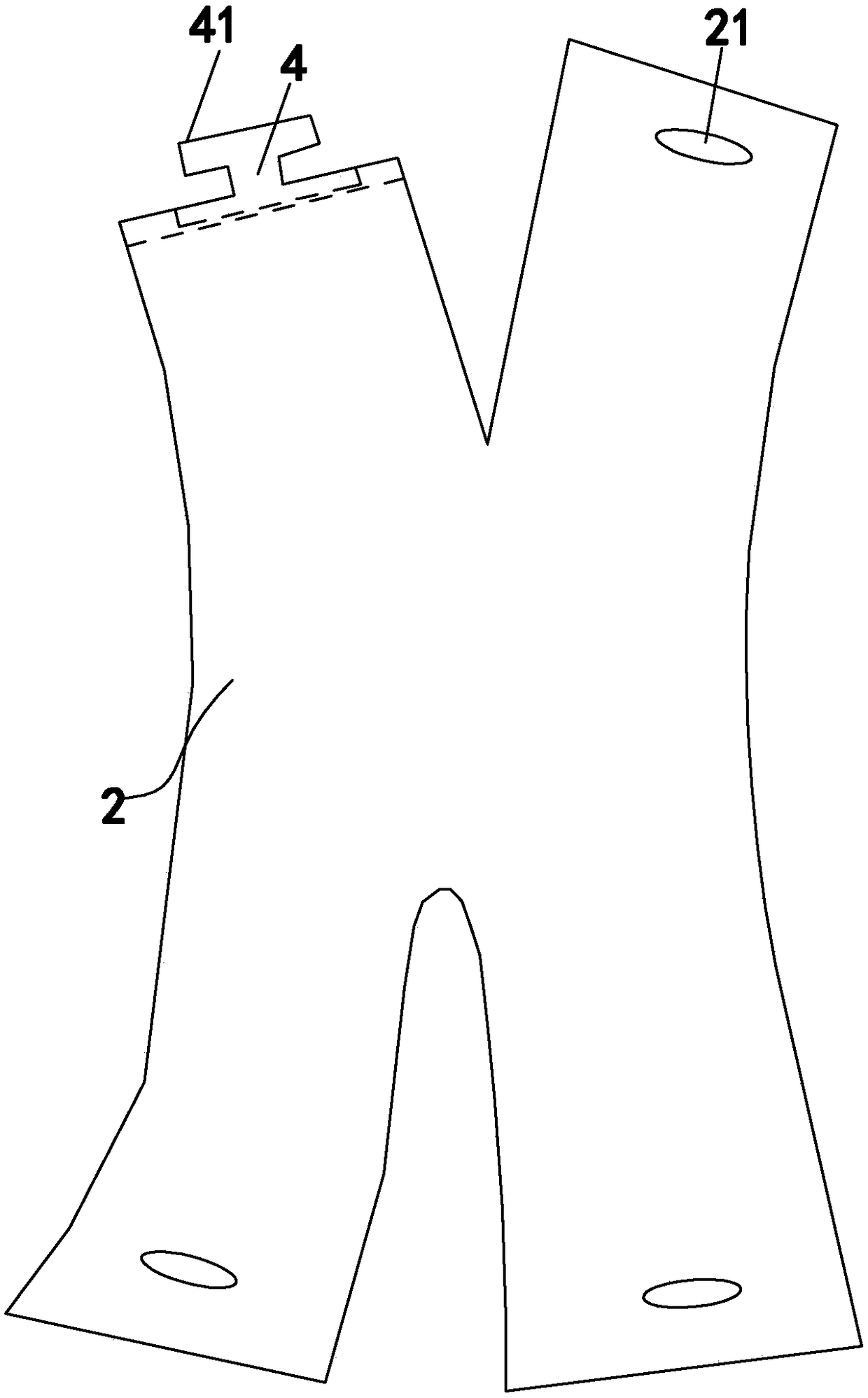

[0024] refer to Figure 1 to Figure 4 , the embodiment of the present invention discloses an assembled shoe, comprising a shoe sole 1 and a detachable shoe upper 2 arranged on the shoe sole 1, a connecting buckle 3 is fixed on the side edge of the surface of the shoe sole 1, and the connecting button 3 is spaced apart from each other. The side edge of the upper surface of the sole 1 is foamed together with the sole and connected as a whole. The upper surface of the connecting buckle 3 is provided with an opening groove 31, and the connecting buckle 3 located on the upper rear and upper side of the two sides of the opening groove 31 is also provided with Block 32, the two sides of the connecting buckle 3 are also provided with a foam sheet inserting groove cavity 33 for the foam sheet to be inserted into, and the vamp 2 is a cut-out integrated soft sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com