Sewing machine used for making dustproof clothes

A technology for sewing machines and dust clothes, which is applied in the direction of sewing machine components, machine needles, cloth feeding mechanisms, etc., which can solve the problems of low manual sewing efficiency, increased production costs, and different sewing effects, so as to improve sewing efficiency and accuracy , the effect of increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail,

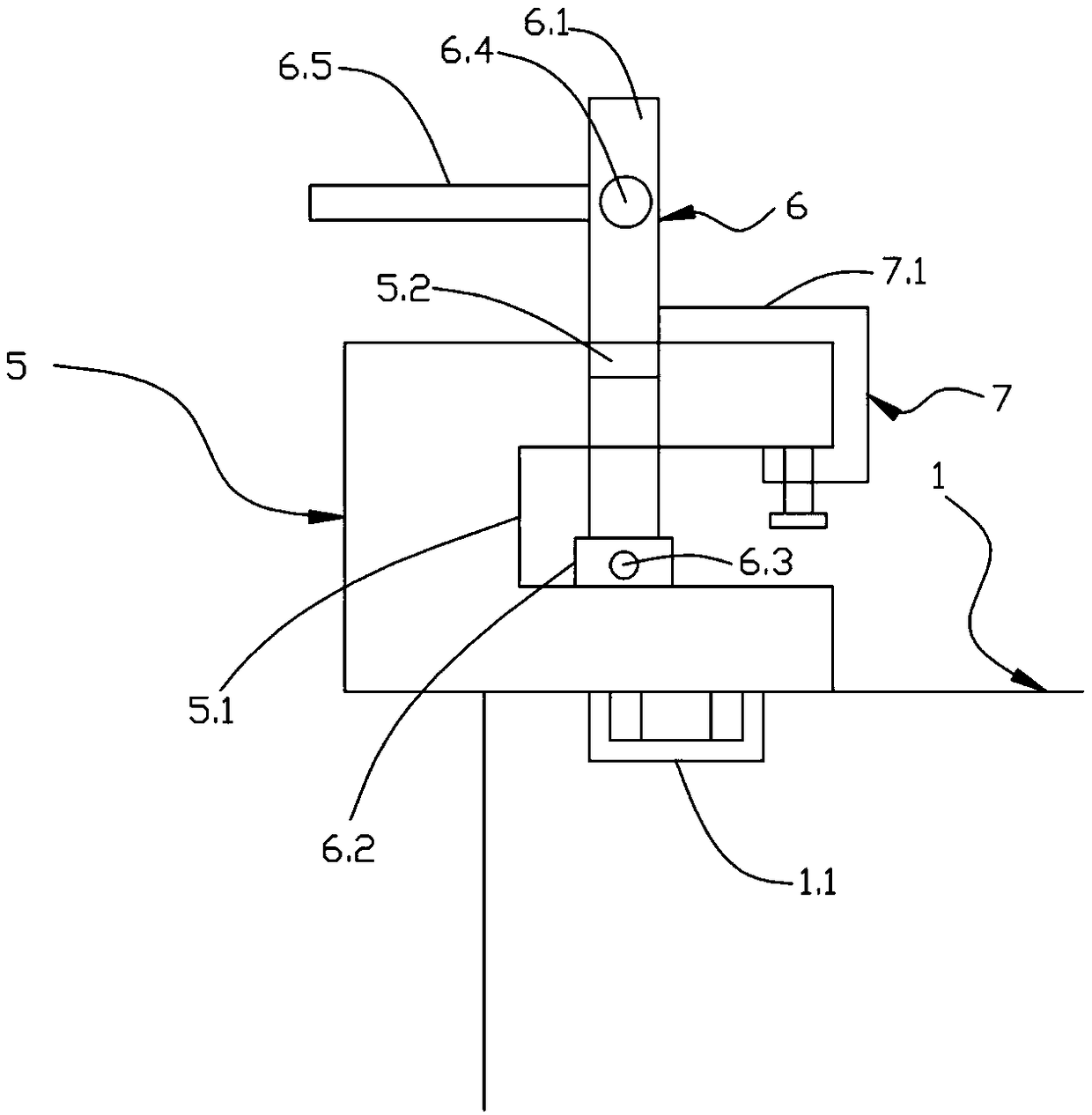

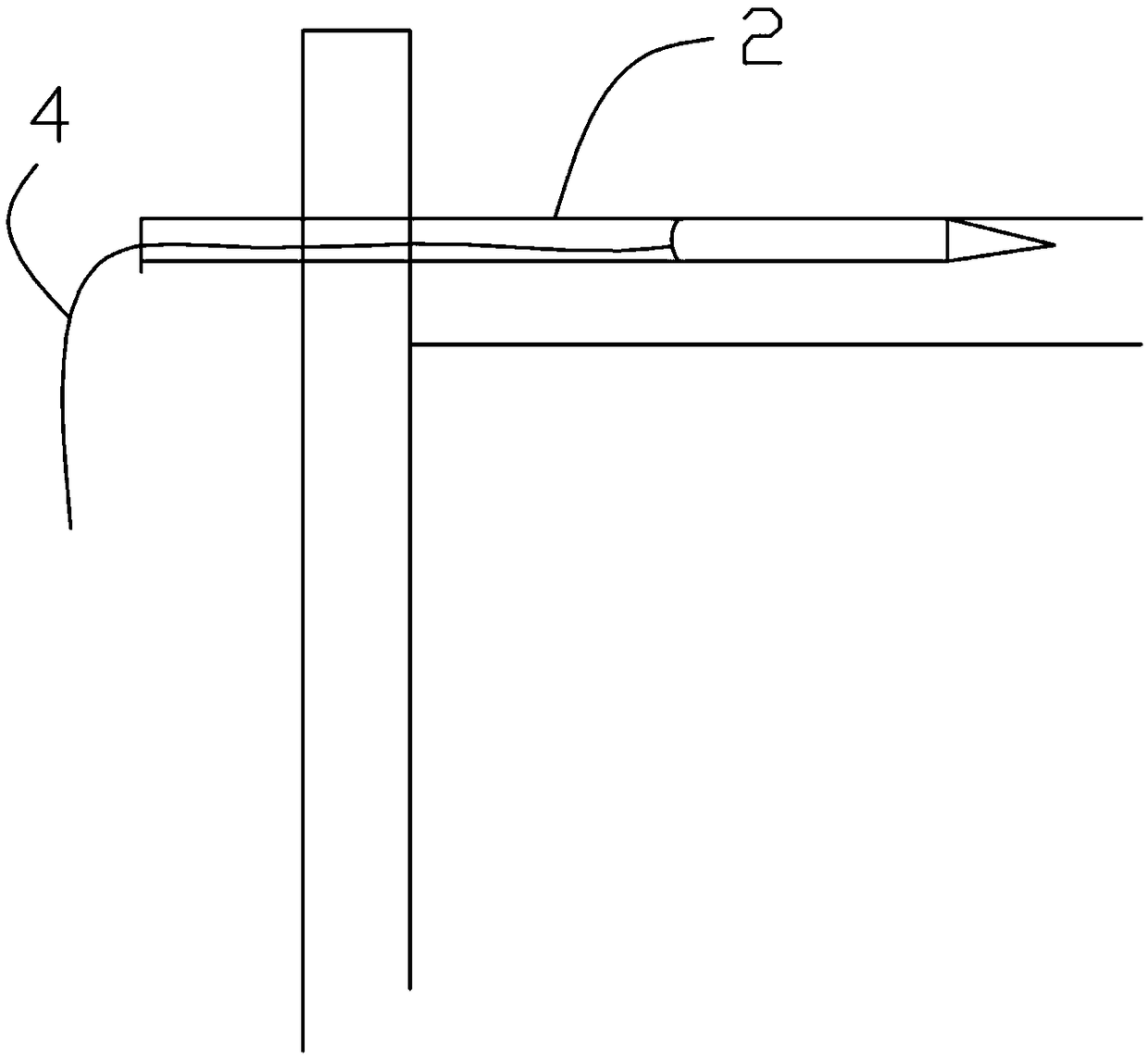

[0031] Such as Figure 1 to Figure 3 Shown, a kind of sewing machine for making dustproof clothes, it comprises: frame 1, casing 5, pressing device 6 and lead wire 4, wherein,

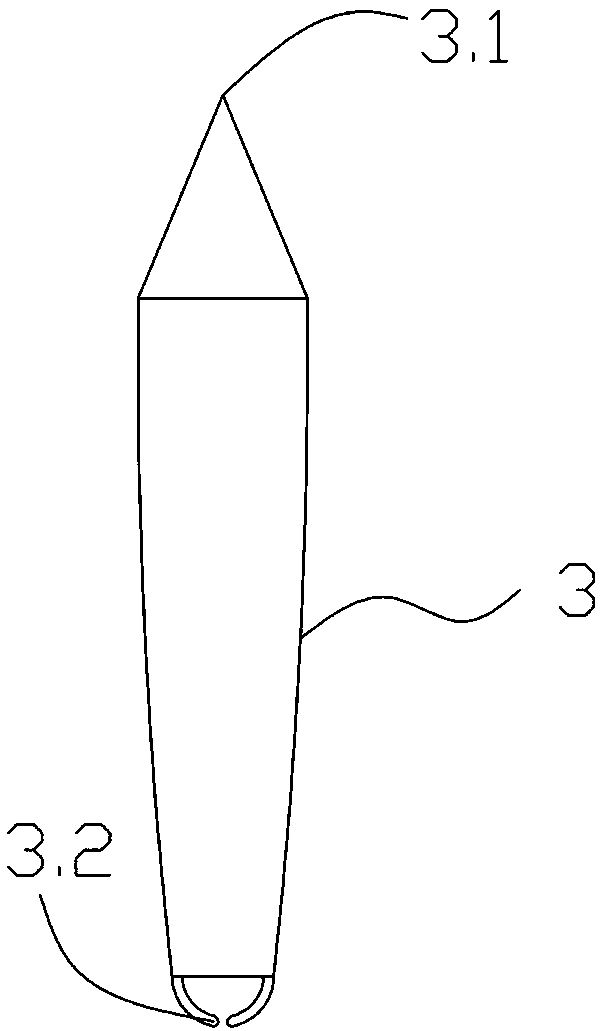

[0032] A guide rail 1.1 is arranged on the table of the frame 1 along its length direction, and a hollow tubular insertion rod 2 is installed on one side of the frame 1, and the end of the insertion rod 2 facing away from the frame 1 is detachably connected with a threading needle 3 ;

[0033] Wherein, the threading needle 3 includes a threading needle body, needle heads 3.1 located at both ends of the threading needle body, and a connection part 3.2. The lead wire 4 can be passed through the connection part 3.2. limit strip,

[0034] Wherein, the distance between the limit strips of the wiring part 3.2 is 0.2 mm to 0.3 mm, so that the threading needle 3 can be separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com