Ballast and ballastless combined track structure laying method

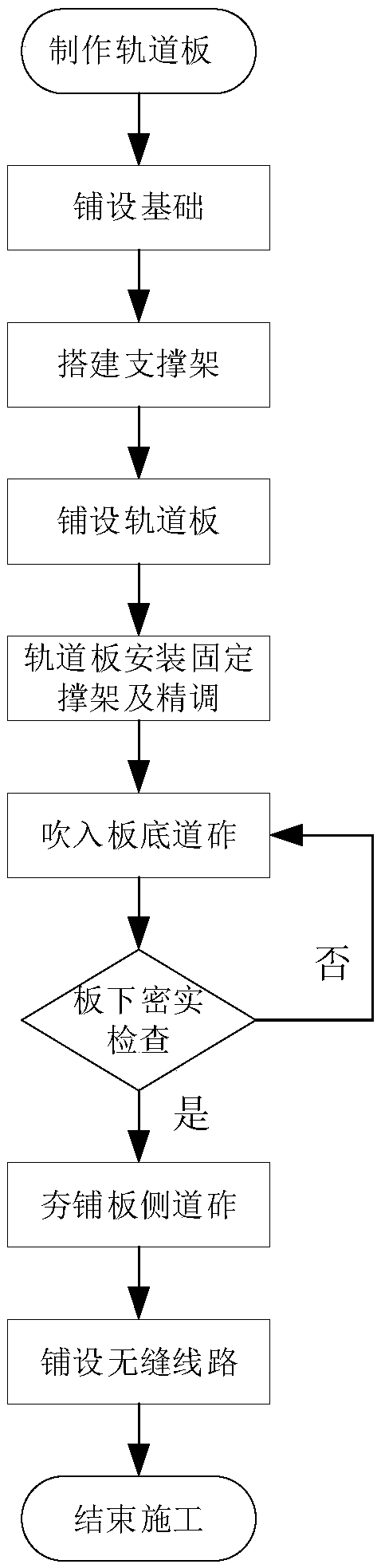

A laying method and track technology, applied in track, track laying, track maintenance, etc., can solve the needs of railway lines that are not suitable for active geological fault zones, concrete does not have the ability to quickly repair and adjust, and there is no laying method for track structures, etc. problems, to achieve the effect of flexible laying method, good compactness and integrity, and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0044] This embodiment is only described for the differences of Embodiment 1, and the similarities are not described again.

[0045] After step 5 is completed, filling materials can be injected into the ballast layer 4, and the filling materials include foaming materials and adhesive materials.

[0046] Foaming materials (such as foamed concrete) fill the gaps between crushed stone particles to increase the compactness of the ballast layer; restrict the movement and rotation of the ballast to improve the integrity of the ballast layer 4; evenly distribute the force of the ballast to protect the ballast Ballast; the filling and hardening process of the filling material can be used to achieve high-precision positioning and adjustment requirements; the low-strength characteristics of the foam material can be used to facilitate demolition and reconstruction of the ballast layer when necessary to meet maintenance needs.

[0047] Adhesive materials (such as ballast glue and asphalt)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com